Honeycomb core panels are revolutionizing industries with their lightweight yet durable construction. From aerospace applications to the construction industry, these panels offer a high strength-to-weight ratio that makes them an ideal choice for a wide range of projects. Made from sustainable building materials, honeycomb core panels provide not only structural integrity but also excellent thermal insulation and acoustic properties. They are widely used in interior design and furniture manufacturing, adding versatility to their list of attributes.

With their lightweight nature and sustainable properties, honeycomb core panels are an innovative solution for various industries. Whether it’s for aerospace engineering, the construction industry, or interior design, these panels offer a reliable and durable option for any project.

Key Takeaways:

- Honeycomb core panels are lightweight yet durable, making them ideal for various applications.

- They have a high strength-to-weight ratio, providing structural integrity in aerospace and construction projects.

- These panels are made from sustainable building materials, contributing to environmentally friendly practices.

- Honeycomb core panels offer excellent thermal insulation and acoustic properties, enhancing the comfort and functionality of spaces.

- They are widely utilized in interior design and furniture manufacturing due to their versatility and aesthetic appeal.

Types of Honeycomb Core Panels

Honeycomb core panels are available in various types, each with its own unique characteristics and applications. Understanding the different types can help you choose the right honeycomb core panel for your specific needs.

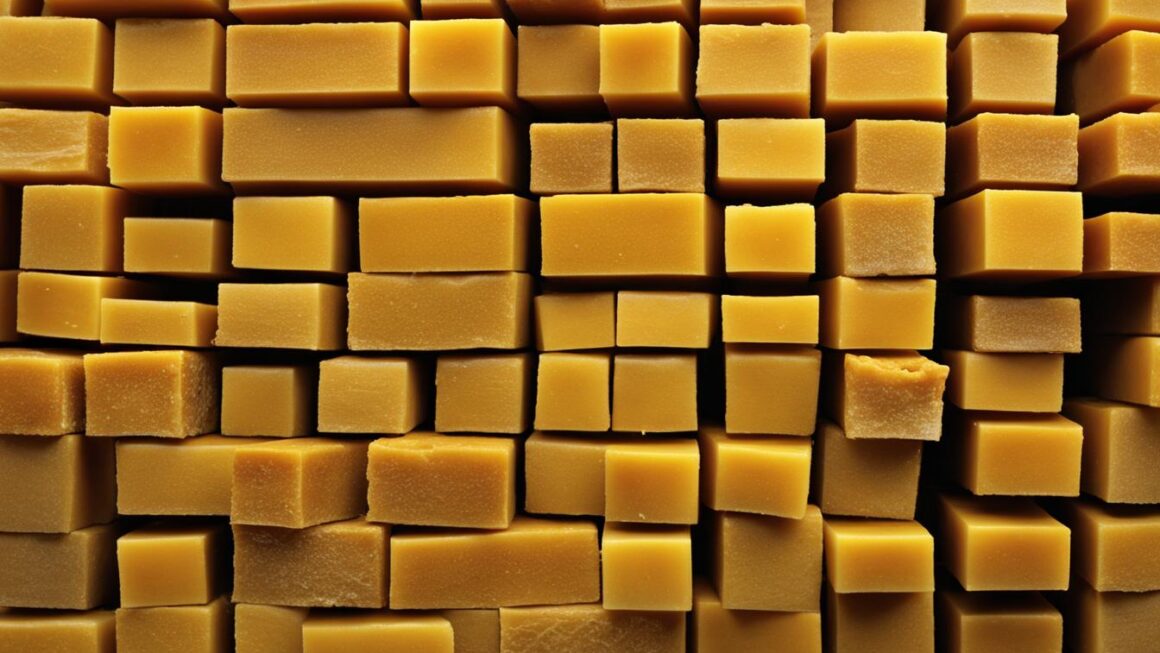

1. Aluminum Honeycomb Core Panels

Aluminum honeycomb core panels are widely used in aerospace applications and the construction industry. These panels are made with aerospace-grade adhesive for bonding and feature micro-aperture cells. They can be purchased in raw blocks or slices and are available in fully expanded form. Aluminum honeycomb core panels provide excellent strength-to-weight ratio and are known for their durability and lightweight properties.

2. Thermoplastic Film Honeycomb Panels

Thermoplastic film honeycomb panels are another type of honeycomb core panel. These panels offer better weather performance and are commonly used in applications where weather resistance is crucial. They are made with a thermoplastic film and provide excellent strength and durability.

3. Stone Honeycomb Panels

Stone honeycomb panels are a popular choice for interior design and architectural projects. These panels feature proven epoxy adhesive and come with different surface options, such as stone, porcelain, and ceramic. Stone honeycomb panels provide a beautiful aesthetic and offer the benefits of lightweight construction and easy installation.

4. Fiberglass Honeycomb Panels

Fiberglass honeycomb panels utilize single-layer fiberglass sheets for enhanced bonding properties. These panels have a rough surface finish, making them suitable for stone veneer lamination. Fiberglass honeycomb panels are commonly used in applications that require high strength and durability.

Overall, the different types of honeycomb core panels offer a wide range of options for various applications. By understanding the specific characteristics of each type, you can select the most suitable honeycomb core panel for your project.

Applications of Honeycomb Core Panels

Honeycomb core panels are highly versatile and find applications in various industries. Let’s explore some of the key areas where these panels are commonly used:

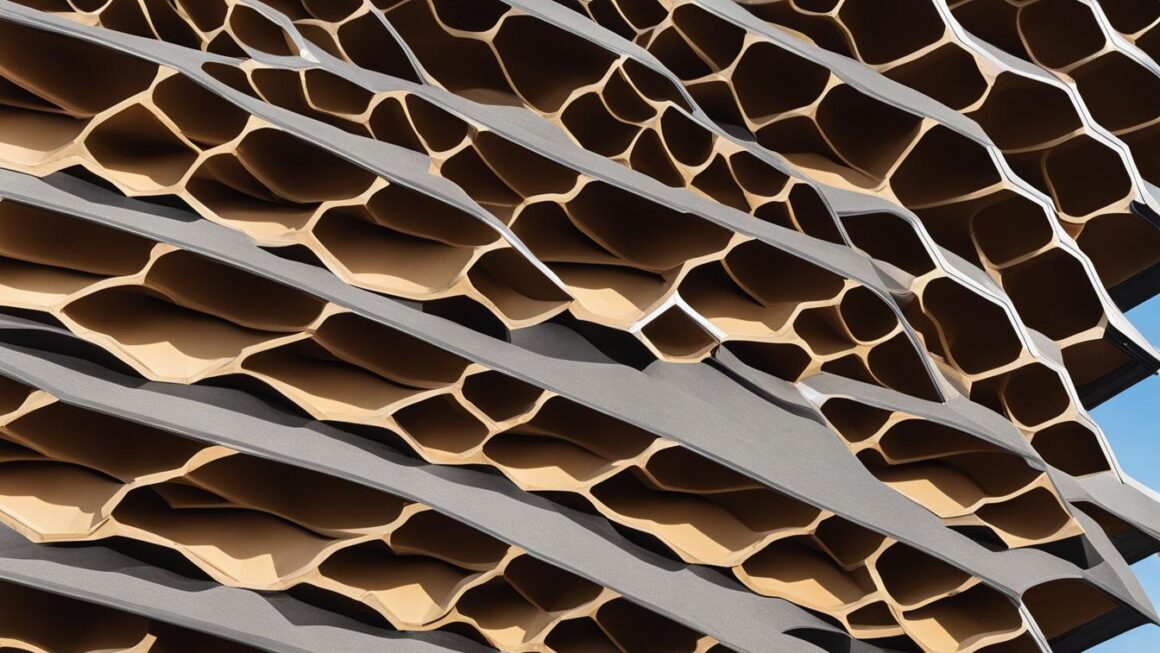

Exterior Cladding

One of the primary applications of honeycomb core panels is in exterior cladding for buildings. These lightweight panels provide a durable and visually appealing solution for enhancing the aesthetics and energy efficiency of structures. The honeycomb structure offers excellent strength-to-weight ratio, enabling architects and builders to create innovative designs while ensuring structural integrity.

Interior Use

In addition to exterior cladding, honeycomb core panels are also widely utilized for interior applications. The panels can be used for wall partitions, ceilings, and flooring, providing a lightweight alternative to traditional construction materials. Their versatility allows for easy integration with various architectural styles, making them a popular choice in interior design projects.

Aerospace Applications

Honeycomb core panels have long been favored in the aerospace industry due to their exceptional strength and light weight. These panels are utilized in aircraft construction to reduce weight and improve fuel efficiency. They provide structural stability, impact resistance, and thermal insulation, making them ideal for aerospace applications where weight reduction is critical.

Automotive Industry

The automotive industry also benefits from the use of honeycomb core panels. These panels are incorporated into vehicle components such as floorboards, interior panels, and body structures. The lightweight nature of honeycomb core panels helps to reduce the overall weight of vehicles, contributing to increased fuel efficiency and improved performance.

Architectural Projects

Honeycomb core panels offer architects and designers a versatile solution for various architectural projects. Whether used for creating unique facades, decorative elements, or structural components, these panels provide a balance of aesthetics, performance, and sustainability. The ability to customize the panels to meet specific project requirements further enhances their appeal in architectural applications.

Furniture Manufacturing

The furniture manufacturing industry also relies on honeycomb core panels for their lightweight and sustainable properties. These panels are used for crafting lightweight yet sturdy furniture pieces with modern designs. Honeycomb core panels provide an excellent foundation for creating functional and aesthetically pleasing furniture that can withstand daily use and transportation.

In summary, honeycomb core panels have a wide range of applications that extend beyond traditional construction. Whether it’s for exterior cladding, interior use, aerospace applications, automotive industry, architectural projects, or furniture manufacturing, these panels offer lightweight, durable, and versatile solutions for various industries.

Benefits of Honeycomb Core Panels

Honeycomb core panels offer numerous benefits that make them a popular choice for various applications. The lightweight nature of these panels makes them easy to handle and install, reducing the time and effort required for installation. Despite their lightweight, honeycomb core panels have a high strength-to-weight ratio, providing excellent durability and structural integrity. This makes them suitable for both interior and exterior applications, where strength and durability are essential.

In addition to their strength and durability, honeycomb core panels offer excellent thermal insulation and acoustic properties. The honeycomb structure of these panels creates air pockets, which act as a barrier against heat transfer, providing effective thermal insulation for buildings and structures. The acoustic properties of honeycomb core panels make them ideal for applications where sound insulation is crucial, such as recording studios or concert halls.

Furthermore, honeycomb core panels are weather-resistant and can withstand extreme conditions without losing their structural integrity. They are resistant to moisture, UV rays, and temperature changes, making them suitable for outdoor applications. Whether it’s extreme heat, heavy rain, or freezing temperatures, honeycomb core panels can withstand the elements, making them a reliable solution for long-lasting performance.

Case Studies: Honeycomb Core Panel Projects

Several notable projects have utilized honeycomb core panels, showcasing their versatility and durability. These projects include:

- Kings Domain Residential Tower: This project in Melbourne, Australia, incorporated stone honeycomb panels with travertine veneer, creating an elegant and sustainable exterior finish.

- CTF Tower Guangzhou: The CTF Tower in Guangzhou, China, also utilized stone honeycomb panels with travertine veneer, adding a touch of luxury and durability to the building’s design.

- Shenzhen Airport: Shenzhen Airport opted for PVDF coated aluminum honeycomb panels, taking advantage of their lightweight nature and superior weather resistance.

- Xi’an Airport: Similar to Shenzhen Airport, Xi’an Airport also utilized PVDF coated aluminum honeycomb panels but in a larger area, showcasing the panels’ adaptability and structural integrity.

- Zhuhai Library: Zhuhai Library utilized PVDF coated aluminum honeycomb panels, highlighting their aesthetic appeal and ability to withstand harsh weather conditions.

- The Parisian Macau: The Parisian Macau project incorporated stone honeycomb panels, adding a touch of elegance and durability to the luxurious resort.

- Bantian International School: Bantian International School used stone honeycomb panels with sandstone veneer, providing a visually appealing and sustainable solution for the construction of their educational facility.

Table: Summary of Honeycomb Core Panel Projects

| Project | Panel Type | Material | Finish |

|---|---|---|---|

| Kings Domain Residential Tower | Stone Honeycomb Panels | Travertine Veneer | Elegant and Sustainable |

| CTF Tower Guangzhou | Stone Honeycomb Panels | Travertine Veneer | Luxurious and Durable |

| Shenzhen Airport | PVDF Coated Aluminum Honeycomb Panels | Aluminum | Lightweight and Weather Resistant |

| Xi’an Airport | PVDF Coated Aluminum Honeycomb Panels | Aluminum | Adaptable and Structurally Sound |

| Zhuhai Library | PVDF Coated Aluminum Honeycomb Panels | Aluminum | Aesthetically Pleasing and Weatherproof |

| The Parisian Macau | Stone Honeycomb Panels | Various Stone Options | Luxurious and Durable |

| Bantian International School | Stone Honeycomb Panels | Sandstone Veneer | Visually Appealing and Sustainable |

These case studies highlight the wide range of applications for honeycomb core panels and their ability to enhance the aesthetics, durability, and sustainability of various projects.

Quality Control of Honeycomb Core Panels

Honeycomb core panel manufacturers prioritize quality control to ensure the durability and performance of their products. They adhere to ISO 9001 standards, which establish rigorous production standards to maintain the highest level of quality. To achieve this, manufacturers employ experienced QC staff who are responsible for monitoring the manufacturing process and conducting thorough inspections.

An essential aspect of quality control is the utilization of in-house laboratories. These facilities allow manufacturers to perform bonding performance tests, ensuring that the panels meet the required standards. By conducting these tests, any potential defects or issues can be identified and addressed promptly, guaranteeing that only high-quality honeycomb core panels are delivered to customers.

Through ISO 9001 standards, experienced QC staff, and in-house laboratories, honeycomb core panel manufacturers maintain stringent quality control measures. This commitment to quality ensures that the panels meet the necessary bonding performances and are free from defects, delivering reliable and durable products to meet the diverse needs of various industries.

Quality Control Measures for Honeycomb Core Panels

Quality control measures for honeycomb core panels include adhering to ISO 9001 standards, employing experienced QC staff, and maintaining in-house laboratories. These measures are crucial to ensuring the panels’ manufacturing process meets the required production standards and that the final products are of the highest quality.

- ISO 9001 standards: Honeycomb core panel manufacturers follow ISO 9001 standards, which set guidelines for quality management systems. These standards ensure consistent quality and help manufacturers meet customer expectations.

- Experienced QC staff: Manufacturers assign experienced quality control staff to monitor the production process and conduct inspections. These staff members are responsible for ensuring that every honeycomb core panel meets the required standards and specifications.

- In-house laboratories: In-house laboratories allow manufacturers to perform bonding performance tests. These tests assess the panels’ strength, durability, and bonding capabilities, ensuring they meet the necessary standards and specifications.

By implementing these quality control measures, honeycomb core panel manufacturers guarantee that their products meet the highest industry standards, providing customers with reliable and durable solutions for their applications.

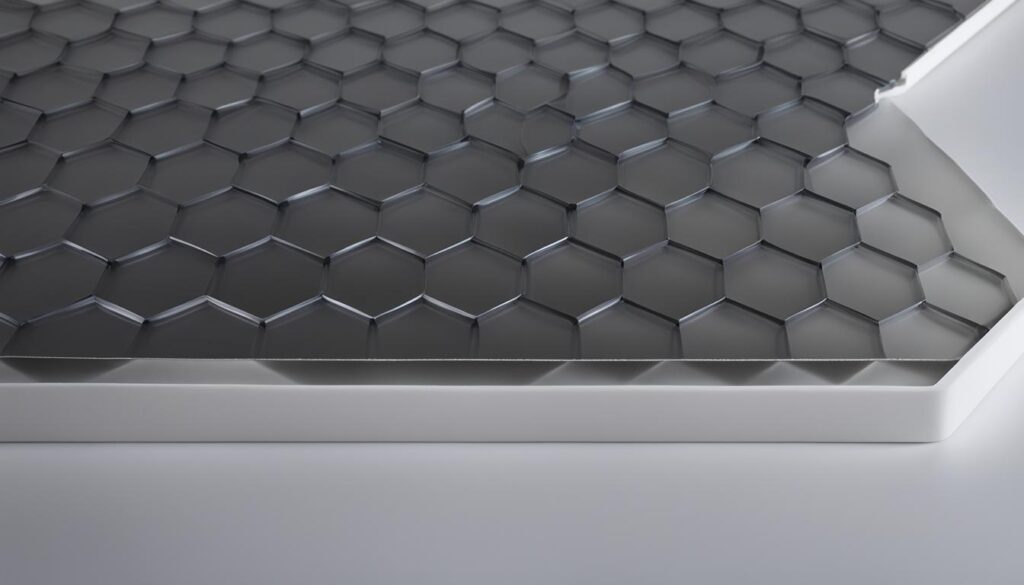

Fiberglass PP Honeycomb Panels

Fiberglass PP honeycomb panels are a lightweight composite material that combines the strength of fiberglass sheets with the structural integrity of a polypropylene honeycomb core. These panels are designed to provide a durable and versatile solution for various applications. With their unique properties, fiberglass PP honeycomb panels offer several advantages.

Corrosion resistance is one of the key benefits of fiberglass PP honeycomb panels. The fiberglass sheets and polypropylene core are impervious to the effects of moisture and chemicals, making them suitable for use in environments where corrosion is a concern. This characteristic ensures the longevity of the panels, allowing them to withstand harsh conditions.

Another advantage of fiberglass PP honeycomb panels is their anti-vibration effects. The combination of fiberglass and the honeycomb structure absorbs vibrations, reducing the impact on the surrounding environment. This feature is particularly valuable in applications where vibration control is crucial, such as in the automotive and aerospace industries.

Fiberglass PP honeycomb panels are lightweight yet offer high strength properties. This makes them easy to handle and install, while still providing excellent structural support. The lightweight nature of these panels also contributes to their versatility, as they can be used in various applications that require a lightweight and durable solution.

Applications and Advantages of Fiberglass PP Honeycomb Panels

Below is a summary of the key applications and advantages of fiberglass PP honeycomb panels:

- Lightweight and high strength, offering structural support without adding excessive weight

- Corrosion resistance, making them suitable for use in environments with moisture and chemicals

- Anti-vibration effects, reducing vibrations in applications where vibration control is crucial

- Easy installation, thanks to their lightweight nature

- Wide range of applications, including vehicle production, home renovation, sporting tools, and building materials

Fiberglass PP honeycomb panels have proven to be a reliable solution for industries that require a lightweight yet durable material. From automotive and aerospace applications to home renovation and sporting tool manufacturing, these panels offer a combination of strength, corrosion resistance, and ease of installation. With their numerous advantages, fiberglass PP honeycomb panels continue to find new applications in various industries.

Applications and Advantages of Fiberglass PP Honeycomb Panels

Fiberglass PP honeycomb panels offer numerous advantages and find applications in a wide range of industries. These lightweight panels provide high strength properties, making them suitable for various purposes. Let’s explore some of the key applications and advantages of fiberglass PP honeycomb panels:

Applications of Fiberglass PP Honeycomb Panels

Fiberglass PP honeycomb panels are widely used in vehicle production for their lightweight nature and durability. They are commonly utilized in the automotive industry for interior panels, roof liners, trunk covers, and door panels. Due to their high strength properties, these panels contribute to the overall safety and efficiency of vehicles.

In the field of home renovation, fiberglass PP honeycomb panels offer a versatile solution. They can be used for wall cladding, furniture, partition walls, and ceilings. These panels provide a lightweight alternative to traditional building materials, making them ideal for residential projects.

Sporting tools and equipment also benefit from the use of fiberglass PP honeycomb panels. From racquets to hockey sticks, these lightweight panels enhance performance by providing strength and durability. Their resistance to weather conditions and chemicals makes them suitable for outdoor sporting applications.

In the construction industry, fiberglass PP honeycomb panels are utilized for building materials such as façade cladding, roofing, and flooring. These panels offer weather resistance, waterproof properties, and high strength, making them a reliable choice for architectural projects.

Advantages of Fiberglass PP Honeycomb Panels

- Lightweight: Fiberglass PP honeycomb panels are incredibly lightweight, making them easy to handle and install. They reduce the overall weight of applications without compromising strength or durability.

- High Strength: Despite their lightweight nature, fiberglass PP honeycomb panels exhibit exceptional strength properties. They can withstand high loads and provide structural integrity.

- Waterproof: These panels are resistant to water and moisture, making them suitable for indoor and outdoor applications where water resistance is crucial.

- Weather Resistance: Fiberglass PP honeycomb panels can withstand extreme weather conditions, including UV radiation, temperature fluctuations, and humidity.

- Chemical Resistance: These panels offer excellent resistance to chemicals, including solvents and acids, making them suitable for applications exposed to harsh chemical environments.

- Recyclable: Fiberglass PP honeycomb panels are recyclable, contributing to sustainable practices and reducing environmental impact.

With their lightweight, high strength, and various advantages such as waterproof and weather resistance, fiberglass PP honeycomb panels are an ideal choice for applications in vehicle production, home renovation, sporting tools, and building materials. These versatile panels offer durability and performance while meeting the specific needs of different industries.

| Application | Advantages |

|---|---|

| Vehicle Production | Lightweight, high strength, durability |

| Home Renovation | Lightweight, versatility, waterproof |

| Sporting Tools | Lightweight, high strength, weather resistance |

| Building Materials | Lightweight, weather resistance, chemical resistance |

As seen in the table, fiberglass PP honeycomb panels offer significant advantages across various applications. Their lightweight nature, high strength, waterproof and weather resistance properties, as well as chemical resistance, make them a reliable choice for industries seeking durable, versatile, and efficient solutions.

Conclusion

Honeycomb core panels are a lightweight and durable solution that offers a high strength-to-weight ratio, making them ideal for various applications. Whether it’s in aerospace, construction, interior design, or furniture manufacturing, these panels prove to be versatile and reliable.

With their lightweight properties, honeycomb core panels are easy to handle and install, providing convenience in various industries. Despite their lightness, they are highly durable, ensuring long-lasting performance in different environments.

These panels also offer additional benefits such as thermal insulation and acoustic properties, making them suitable for a wide range of applications. Their sustainability and customizable nature further enhance their versatility, making honeycomb core panels an excellent choice for architects, designers, and manufacturers.

FAQ

What are honeycomb core panels?

Honeycomb core panels are versatile and lightweight sandwich panels that offer a high strength-to-weight ratio. They are made from sustainable building materials and provide excellent thermal insulation and acoustic properties.

What types of honeycomb core panels are available?

There are different types of honeycomb core panels available, including aluminum honeycomb core panels, thermoplastic film honeycomb panels, stone honeycomb panels, and fiberglass honeycomb panels.

Where are honeycomb core panels commonly used?

Honeycomb core panels are commonly used in aerospace applications, the construction industry, interior design, and furniture manufacturing. They are also used for exterior cladding in buildings and in the automotive industry.

What are the benefits of honeycomb core panels?

Honeycomb core panels are lightweight, durable, and offer good thermal insulation and acoustic properties. They are weather-resistant and can be easily installed. Additionally, they can be customized to meet specific requirements.

Can you provide examples of projects that have utilized honeycomb core panels?

Yes, notable projects that have used honeycomb core panels include the Kings domain residential tower in Melbourne, the CTF Tower in Guangzhou, Shenzhen Airport, Xi’an Airport, Zhuhai Library, The Parisian Macau, and Bantian International School.

How do honeycomb core panel manufacturers ensure quality control?

Honeycomb core panel manufacturers follow ISO 9001 standards, have experienced quality control staff, and utilize in-house laboratories to conduct bonding performance tests and address any potential defects or issues.

What are fiberglass PP honeycomb panels?

Fiberglass PP honeycomb panels are a lightweight composite material that consists of fiberglass sheets and a polypropylene honeycomb core. They offer high strength, corrosion resistance, and anti-vibration effects.

Where are fiberglass PP honeycomb panels used?

Fiberglass PP honeycomb panels are used in various industries, including vehicle production, home renovation, sporting tools, and as building materials. They are suitable for environments that require a lightweight and durable solution.

In summary, what are the key features of honeycomb core panels?

Honeycomb core panels are a lightweight and durable solution with a high strength-to-weight ratio. They offer thermal insulation, acoustic properties, and can be customized for specific applications.