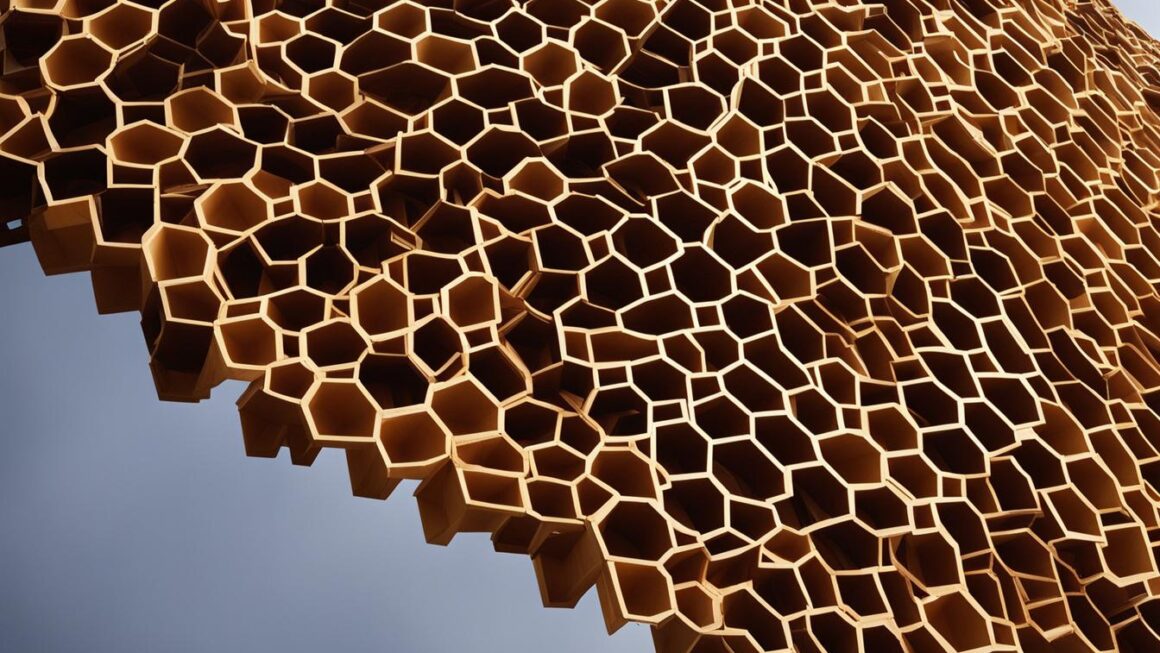

Honeycomb construction is a revolutionary building technique that offers lightweight and efficient solutions for both residential and commercial projects. These structures consist of an array of hollow cells formed between thin vertical walls, providing minimal density and high strength properties. Honeycomb structures are widely used in the aerospace industry and have applications in various fields such as packaging materials and sporting goods. Inspired by the efficient geometry of natural honeycombs found in beehives, honeycomb construction has become a preferred choice for architects and builders.

Key Takeaways:

- Honeycomb construction is a lightweight and efficient building technique.

- It consists of hollow cells formed between thin vertical walls.

- Honeycomb structures have applications in aerospace, packaging, and sporting goods.

- The geometry of natural honeycombs inspires honeycomb construction.

- Honeycomb construction offers high strength properties with minimal density.

The History of Honeycomb Structures

Honeycomb structures have a rich history that dates back centuries. In Greek mythology, the legendary craftsman Daedalus is said to have created the first man-made honeycomb using lost wax casting, using gold as the material. This early example of ancient honeycomb manufacturing showcases the ingenuity and geometric efficiency that have been associated with honeycomb structures throughout history.

Ancient Greek mathematicians Euclid and Zenodorus also recognized the geometric efficiency of the hexagonal shape, which is the primary shape found in honeycombs. This recognition of the hexagonal shape’s strength and efficiency has been influential in the design of honeycomb structures. One notable example of the use of honeycomb structures in ancient times is the Pantheon in Rome, known for its impressive dome that features honeycomb-like patterns in its construction.

“The use of honeycomb structures in ancient times and the recognition of their geometric efficiency have laid the foundation for the development and application of honeycomb construction techniques throughout history.” – Honeycomb Construction Expert

Throughout the centuries, notable scientists and thinkers have also discussed the advantages of honeycomb structures. Renowned figures such as Galileo Galilei, Robert Hooke, and Charles Darwin have all recognized the strength and efficiency of honeycomb structures and their potential applications in various fields. As scientific understanding and materials technology advanced, honeycomb construction techniques for structural applications were proposed and developed in the early 20th century, leading to further advancements in materials and manufacturing processes that continue to this day.

| Historical Figures | Contributions to Honeycomb Structures |

|---|---|

| Daedalus | Created the first man-made honeycomb using lost wax casting |

| Euclid and Zenodorus | Recognized the geometric efficiency of the hexagonal shape |

| Galileo Galilei, Robert Hooke, Charles Darwin | Discussed the advantages of honeycomb structures |

The history of honeycomb structures reveals the long-standing fascination with their geometric efficiency and strength. From ancient civilizations to the advancements of modern science and technology, honeycomb construction techniques have left an indelible mark on the world of architecture and engineering.

Honeycomb Construction Lightweight and Efficient Building Technique

Manufacturing honeycomb structures involves various production techniques, each suited to different materials and applications. The three traditional techniques used are expansion, corrugation, and molding. In the expansion process, honeycombs are folded from a single sheet of material. The corrugation process involves cutting and bending metal sheets to create honeycomb cells. The molding process utilizes a paper paste glue mixture to create honeycombs. These techniques have evolved over time with advancements in materials and manufacturing processes.

Materials commonly used for honeycomb cores include fiberglass, carbon fiber reinforced plastic, and metal, such as aluminum. Extrusion processes are also employed for thermoplastic honeycomb core production. These versatile honeycomb structures find applications in industries such as aerospace, automotive, furniture, and packaging. They offer lightweight and high-strength solutions, making them ideal for various structural needs.

To highlight the diverse applications of honeycomb construction, here is a table showcasing different honeycomb production techniques and their advantages:

| Honeycomb Production Technique | Advantages |

|---|---|

| Expansion | Efficient use of materials, ease of production |

| Corrugation | High strength, suitable for metal honeycombs |

| Molding | Versatile, cost-effective |

The table illustrates the benefits of each technique, highlighting the unique advantages of expansion, corrugation, and molding in honeycomb production. These techniques contribute to the lightweight, efficient, and sustainable nature of honeycomb construction.

Honeycomb Construction Applications

Honeycomb structures have a wide range of applications across various industries. Let’s explore how honeycomb construction is utilized in the aerospace, automotive, furniture, and packaging industries.

Aerospace Industry

The aerospace industry extensively uses honeycomb structures for manufacturing lightweight and high-performance products. Honeycomb materials are used in the construction of racing shells, gliders, helicopters, and jet aircraft. The honeycomb’s combination of high strength and low weight makes it an ideal choice for achieving optimal performance in aerospace applications.

Automotive Industry

In the automotive industry, honeycomb structures are utilized for both interior and exterior finishes. They provide lightweight solutions without compromising strength and durability. The use of honeycomb panels in automotive construction contributes to fuel efficiency and improved performance. Additionally, honeycomb structures are used in vehicle crash zones to enhance safety by absorbing impact energy.

Furniture Industry

The furniture industry benefits from honeycomb structures due to their lightweight and durable properties. Honeycomb construction allows for the creation of furniture pieces that are easy to transport and install. The furniture industry utilizes honeycomb structures for various applications such as tabletops, countertops, and cabinets. These structures provide strength and stability while reducing the overall weight of the furniture.

Packaging Industry

Honeycomb structures are widely used in the packaging industry for their strength and energy absorption capabilities. They provide excellent protection for fragile and valuable goods during transit. Honeycomb packaging materials are lightweight, cost-effective, and environmentally friendly. They offer superior cushioning and shock resistance, ensuring the safe transportation of products.

With their lightweight design, high strength-to-weight ratio, and versatility, honeycomb structures continue to revolutionize various industries. Their applications in the aerospace, automotive, furniture, and packaging industries highlight the numerous advantages and benefits they offer. The future of honeycomb construction looks promising, as advancements in materials and manufacturing processes drive further innovation in this efficient building technique.

Advancements in Honeycomb Core Technology

Honeycomb core technology is constantly advancing, leading to improved performance and expanded applications. Manufacturers are continuously developing new and innovative honeycomb core products to meet the evolving needs of various industries. These advancements focus on enhancing surface quality, increasing strength-to-weight ratios, and promoting sustainable production practices.

One significant advancement in honeycomb core technology is the development of cores with smaller cell sizes. Companies like ThermHex Waben have introduced honeycomb cores with finer cell structures, resulting in improved surface quality. These cores are particularly beneficial for applications that require “Class A” surface finishes, such as automotive panels and high-end architectural elements.

“The use of advanced materials in honeycomb core production has also contributed to significant improvements in performance.”

Another area of advancement is the use of advanced materials in honeycomb core production. Materials such as polypropylene have been introduced, offering enhanced strength and durability. These advanced materials provide manufacturers with the ability to tailor honeycomb cores to specific requirements, such as aerospace applications that demand high strength-to-weight ratios.

Additionally, there is a growing focus on carbon neutral production in the honeycomb core industry. Manufacturers are implementing sustainable practices and exploring renewable energy sources to reduce the environmental impact of production processes. By prioritizing carbon neutrality, the industry aims to contribute to global sustainability efforts and create eco-friendly honeycomb core solutions.

| Advancements in Honeycomb Core Technology | Benefits |

|---|---|

| Development of smaller cell sizes | Improved surface quality |

| Use of advanced materials | Enhanced strength-to-weight ratios |

| Focus on carbon neutral production | Sustainability and environmental responsibility |

Benefits of Honeycomb Cladding Systems

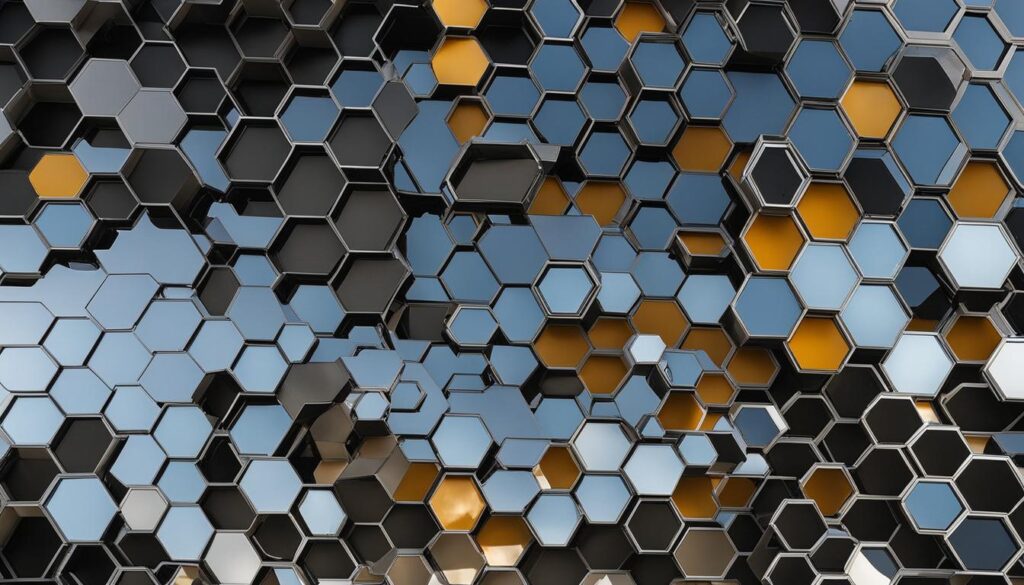

Honeycomb cladding systems offer numerous benefits in the realm of building and construction. One of the key advantages is the use of honeycomb foam building materials, which are versatile and suitable for various applications such as doors, countertops, and cabinets. These foam materials are lightweight, yet provide excellent structural integrity, making them a preferred choice for architects and designers.

Another advantage is the availability of aluminum honeycomb panels, which are highly durable and provide exceptional strength. These panels are commonly used for wall cladding systems, both for interior and exterior use. The lightweight nature of aluminum, combined with the honeycomb structure, results in panels that are not only strong, but also easy to install and transport.

In addition, fiberglass stone honeycomb structural panels offer unique benefits for both interior and exterior purposes. These panels are lightweight, weatherproof, moldproof, and fireproof, making them ideal for a wide range of applications. They provide an excellent combination of durability and aesthetic appeal, allowing architects and designers to create visually stunning and functional structures.

| Advantages of Honeycomb Cladding Systems |

|---|

| Versatile and lightweight honeycomb foam building materials |

| Durable and strong aluminum honeycomb panels for wall cladding systems |

| Lightweight, weatherproof, moldproof, and fireproof fiberglass stone honeycomb structural panels |

Overall, honeycomb cladding systems provide a range of benefits including durability, functionality, and aesthetic appeal. They offer architects and designers the flexibility to create innovative and sustainable designs while meeting the demands of modern construction. As advancements in honeycomb construction continue to evolve, these cladding systems will play a crucial role in shaping the buildings of the future.

Honeycomb Cladding Systems in Building and Construction

Honeycomb cladding systems have become increasingly popular in the building and construction industry due to their numerous advantages and versatility. These systems offer a wide range of cladding materials, including copper and bronze, that provide enhanced protection against environmental damage, while also adding an aesthetic appeal to buildings.

One example of a honeycomb cladding system is the copper cladding system. Copper is a durable and corrosion-resistant material that not only protects the building against weathering but also develops a unique patina over time, adding character to the structure. The use of honeycomb structural designs in copper cladding systems further enhances their efficiency and functionality, allowing for lightweight yet stiff core materials that reduce the weight of the overall structure.

“Honeycomb cladding systems offer durability, functionality, and aesthetic appeal to building projects.”

Another popular option is the bronze cladding system. Bronze is known for its strength and durability, making it an ideal choice for external cladding applications. The combination of bronze with honeycomb structural designs creates a lightweight yet robust cladding system that offers long-term performance and visual appeal.

Table:

| Cladding Material | Key Features |

|---|---|

| Copper | Durable, corrosion-resistant, develops patina |

| Bronze | Strong, durable, visually appealing |

These honeycomb cladding systems provide several advantages in terms of durability, functionality, and aesthetic appeal. They offer enhanced protection against environmental damage, ensuring the longevity of the building. The use of honeycomb structural designs improves the efficiency and functionality of the cladding system, resulting in a lightweight yet strong structure. Additionally, honeycomb cladding systems contribute to the overall sustainability of the building by reducing the weight of materials used and minimizing the environmental impact.

The combination of cladding materials, such as copper and bronze, with honeycomb structural designs makes honeycomb cladding systems an excellent choice for both interior and exterior applications in the building and construction industry.

Advantages of Honeycomb Construction

Honeycomb construction offers several advantages compared to traditional building techniques. One of the key benefits is its lightweight design. The use of honeycomb structures significantly reduces the amount of materials needed, resulting in cost savings and easier transportation and installation. This makes honeycomb construction ideal for projects where weight plays a significant role, such as in aerospace and automotive applications.

Another advantage of honeycomb construction is its cost-efficiency. With reduced material usage and streamlined production processes, honeycomb structures offer a cost-effective solution for both residential and commercial projects. The high strength-to-weight ratio of honeycomb structures provides structural integrity while minimizing the overall weight of the building, resulting in long-term cost savings.

Honeycomb construction also contributes to sustainability efforts. By reducing energy consumption and environmental impact during production and operation, honeycomb structures align with green building practices. Additionally, the use of advanced materials, such as recycled composites, further enhances the sustainability of honeycomb construction. These eco-friendly properties make honeycomb construction a preferred choice for environmentally-conscious builders.

The Benefits of Honeycomb Construction:

- Lightweight design

- Cost-efficiency

- Sustainability

Overall, honeycomb construction offers a range of advantages that make it a desirable building technique. Its lightweight design, cost-efficiency, and sustainability contribute to its growing popularity in various industries. Whether it’s for aerospace, automotive, or residential construction, honeycomb structures provide a strong and efficient solution.

| Advantages of Honeycomb Construction |

|---|

| Lightweight design |

| Cost-efficiency |

| Sustainability |

Future Trends in Honeycomb Construction

The field of honeycomb construction is constantly evolving, with ongoing advancements in materials and manufacturing processes driving innovation and opening up new possibilities. As the demand for lightweight and efficient building techniques continues to grow, researchers and engineers are exploring advanced materials and innovative manufacturing methods to enhance the performance and sustainability of honeycomb structures.

One of the key future trends in honeycomb construction is the development of advanced materials. These materials offer improved strength, durability, and sustainability, making them ideal for a wide range of applications. Advanced composites and nanomaterials, for example, are being investigated for their potential to enhance the properties of honeycomb structures and provide even greater structural integrity.

In addition to advanced materials, innovative manufacturing processes are also shaping the future of honeycomb construction. Technologies such as 3D printing and automated production techniques show promise in streamlining the manufacturing of honeycomb components, reducing costs, and increasing efficiency.

Table: Future Trends in Honeycomb Construction

| Future Trends | Description |

|---|---|

| Advanced Materials | Researchers are exploring the use of advanced composites and nanomaterials to enhance the strength, durability, and sustainability of honeycomb structures. |

| Innovative Manufacturing Processes | Technologies like 3D printing and automated production techniques are being developed to streamline the manufacturing of honeycomb components, improving efficiency and reducing costs. |

| Increased Customization | Advancements in manufacturing processes will allow for greater customization of honeycomb structures, meeting specific design requirements and optimizing performance. |

| Integration of Smart Technologies | The integration of smart technologies, such as sensors and adaptive materials, will enable honeycomb structures to respond to changes in their environment and enhance their functionality. |

These future trends in honeycomb construction hold great potential for advancing the field and expanding its applications. By leveraging advanced materials and innovative manufacturing processes, engineers and designers can push the boundaries of what is possible in terms of lightweight, efficient, and sustainable construction.

Honeycomb Construction Case Studies and Real-World Examples

Honeycomb construction has been successfully implemented in numerous real-world projects, showcasing its effectiveness and versatility in various industries. Let’s explore some notable case studies and examples that highlight the practical applications and benefits of honeycomb structures.

Case Study: North American XB-70 Valkyrie

“The North American XB-70 Valkyrie, an iconic supersonic bomber aircraft, utilized honeycomb construction in its design to achieve optimal strength and lightweight performance.”

One of the most prominent examples of honeycomb construction is the North American XB-70 Valkyrie, an iconic supersonic bomber aircraft developed in the 1960s. The XB-70 Valkyrie incorporated honeycomb structures in its wings and tail sections to achieve optimal strength while keeping the overall weight of the aircraft low. This allowed the XB-70 Valkyrie to reach high speeds and carry heavy payloads, showcasing the superior strength-to-weight ratio of honeycomb structures in aerospace applications.

Case Study: The Pantheon, Rome

“The Pantheon, a marvel of ancient Roman architecture, features a honeycomb dome that has stood the test of time for over two millennia.”

The Pantheon in Rome is another remarkable example of honeycomb construction. Built in the 2nd century AD, the Pantheon showcases the architectural brilliance of the ancient Romans. Its dome, made of concrete and featuring a honeycomb structure, has been standing for over two thousand years. The honeycomb cells in the dome’s construction provide exceptional strength and structural integrity, allowing the Pantheon to withstand the test of time and remain an architectural marvel to this day.

Real-World Example: Modern Architectural Cladding

Modern architectural designs often utilize honeycomb cladding systems to enhance durability and aesthetic appeal. One notable example is the use of honeycomb panels in contemporary skyscrapers. These panels, made from materials such as aluminum or fiberglass, offer lightweight construction, high strength, and weather resistance. They provide both functional and decorative elements to the building’s exterior, showcasing the adaptability and versatility of honeycomb construction in modern construction.

These case studies and real-world examples demonstrate the wide-ranging applications of honeycomb construction in various industries, including aerospace, architecture, and infrastructure. The strength, lightweight design, and longevity offered by honeycomb structures make them an invaluable solution for projects that require optimal structural integrity and efficiency.

Conclusion

In conclusion, honeycomb construction offers a lightweight and efficient building technique that has revolutionized various industries. The honeycomb structures provide high strength properties while minimizing weight and material usage, making them ideal for aerospace, automotive, furniture, packaging, and construction applications.

Honeycomb cladding systems offer numerous advantages, including durability, functionality, and aesthetic appeal. These systems have become integral in modern architectural designs, providing long-lasting protection and enhancing the overall visual appeal of buildings.

Advancements in materials, manufacturing processes, and sustainability practices continue to drive the evolution of honeycomb construction. The future of honeycomb construction holds promise with the development of advanced materials and innovative manufacturing techniques, which will further enhance the strength, durability, and sustainability of honeycomb structures.

Overall, honeycomb construction offers a cost-effective, sustainable, and design-flexible approach to building and construction. Its lightweight nature, high strength-to-weight ratio, and versatility make it a valuable choice for various projects, contributing to the advancement and progress of the construction industry.

FAQ

What is honeycomb construction?

Honeycomb construction is a lightweight and efficient building technique that utilizes an array of hollow cells formed between thin vertical walls, providing minimal density and high strength properties.

What are the traditional production techniques for honeycomb structures?

The three traditional production techniques for honeycomb structures are expansion, corrugation, and moulding. These techniques involve folding honeycombs from a single sheet of material, cutting and bending metal sheets, or utilizing a paper paste glue mixture to create honeycombs, respectively.

What are the applications of honeycomb structures?

Honeycomb structures find applications in various industries, including the aerospace industry for manufacturing aircraft and rockets, the automotive industry for interior and exterior finishes, the furniture industry for lightweight construction, and the packaging industry for strength and energy absorption capabilities.

How does honeycomb construction contribute to sustainability?

Honeycomb construction reduces the amount of materials needed, resulting in cost savings and lower transportation and installation requirements. It also has a high strength-to-weight ratio, reducing energy consumption and environmental impact during production and operation.

What are the benefits of honeycomb cladding systems?

Honeycomb cladding systems offer durability, functionality, and aesthetic appeal. They are versatile and suitable for various applications, such as doors, countertops, and cabinets, and can be custom-designed for specific projects.

What are the advancements in honeycomb core technology?

Advancements in honeycomb core technology include smaller cell sizes for improved surface quality, the use of advanced materials like polypropylene to enhance strength-to-weight ratio, and efforts towards achieving carbon neutral production through renewable energy sources and sustainable practices.

What are some real-world examples of honeycomb construction?

Notable examples of honeycomb construction include the use of honeycomb structures in the aerospace industry for aircraft and rockets, such as the North American XB-70 Valkyrie, and in the construction of large structures like the Pantheon in Rome. Honeycomb cladding systems have also been implemented in modern architectural designs for durability and aesthetic appeal.

What is the future of honeycomb construction?

The future of honeycomb construction lies in advancements in materials and manufacturing processes, such as the development of advanced composites and nanomaterials, as well as innovative techniques like 3D printing. These advancements will drive further innovation in building techniques and enhance the properties of honeycomb structures.