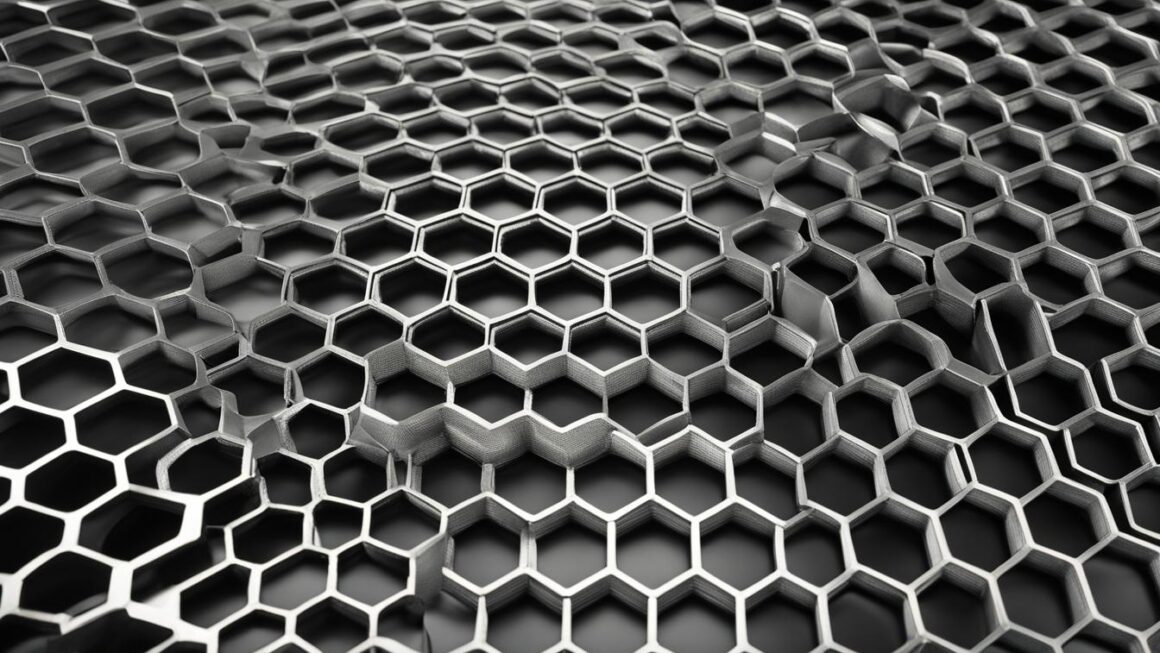

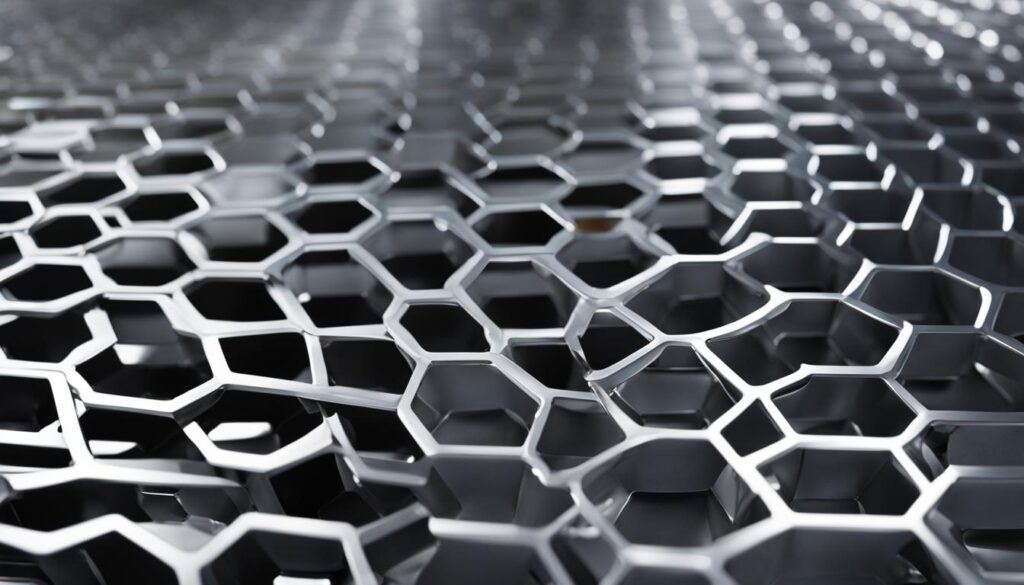

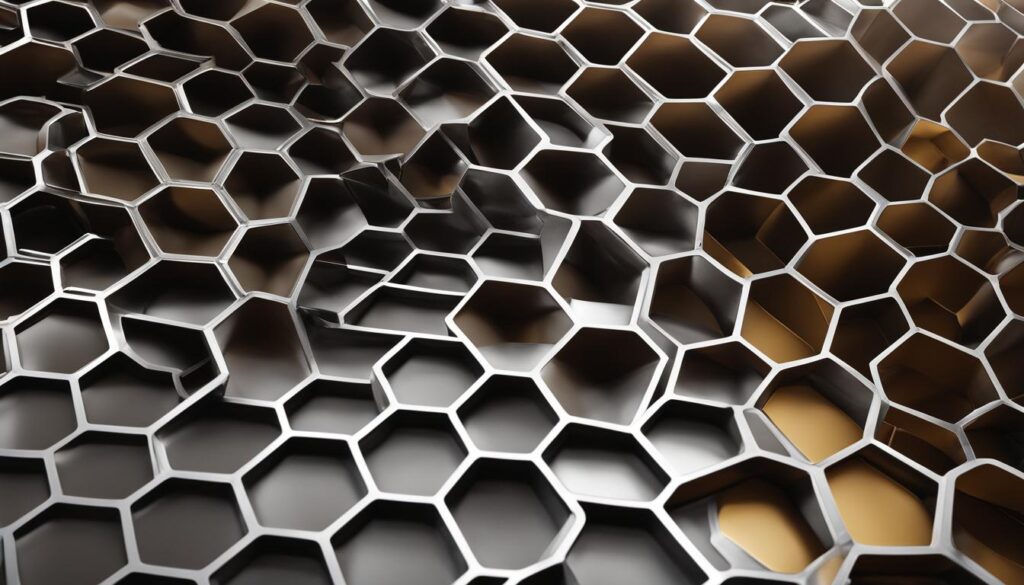

Aluminum honeycomb panels have become increasingly popular in various industries due to their lightweight nature, strength, and versatility. These panels are constructed by bonding a thin sheet of aluminum to a core made of hexagonal aluminum honeycomb. This unique structure provides exceptional strength and rigidity, while also adding durability and resistance to corrosion. The aluminum honeycomb panels find applications in building facades, flooring, partitions, as well as in the aerospace and automotive industries.

Key Takeaways:

- Aluminium honeycomb core panels offer a lightweight solution for numerous industries.

- The hexagonal structure of the honeycomb core provides excellent strength and rigidity.

- Aluminium honeycomb panels are durable and resistant to corrosion.

- These panels are easily installed, reducing labor costs and time.

- Aluminium honeycomb panels provide energy efficiency and insulation properties.

Strength and Durability of Aluminium Honeycomb Core

The hexagonal structure of the aluminum honeycomb core provides exceptional strength and durability to the aluminum honeycomb panels. This unique structure allows the panels to withstand high loads and impacts, making them suitable for various applications that require a high-strength material. The honeycomb structure distributes the load evenly across the panels, ensuring optimal weight-bearing capacity.

In addition to its strength, the aluminum skin bonded to the honeycomb core adds durability and resistance to corrosion. This makes the panels highly resistant to harsh environmental conditions, such as moisture, temperature variations, and UV exposure. As a result, aluminum honeycomb panels are able to maintain their structural integrity and appearance over a long period of time.

The strength and durability of aluminum honeycomb panels make them ideal for use in industries such as aerospace, marine, and automotive. In aircraft, the panels are used for structural components, flooring, and interior cladding. For boats, they are commonly used for hulls, decks, and bulkheads. In the automotive industry, aluminum honeycomb panels can be found in car interiors, body panels, and chassis components, providing lightweight yet robust solutions.

Strength and Durability in Different Industries

The exceptional strength and durability of aluminum honeycomb panels make them highly suitable for use in various industries:

- Aerospace: The lightweight nature and high-strength properties of aluminum honeycomb panels make them an excellent choice for aircraft interiors, flooring, and structural components.

- Marine: The corrosion-resistant properties of the panels make them ideal for boat interiors, hulls, decks, and bulkheads.

- Automotive: The strength and lightweight nature of aluminum honeycomb panels contribute to improved fuel efficiency and performance in automobiles, where weight reduction is crucial.

Overall, the strength and durability of aluminum honeycomb panels make them a reliable and long-lasting material for a wide range of applications in multiple industries.

https://www.youtube.com/watch?v=idInZKGcI74

Lightweight and Easy Installation of Aluminium Honeycomb Core

When it comes to choosing a material for construction projects, finding a lightweight option that is easy to install can be a game-changer. That’s where aluminum honeycomb core panels come in. With their unique structure and properties, these panels offer a range of advantages that make them a preferred choice for many industries.

The lightweight nature of aluminum honeycomb panels makes them incredibly easy to handle and install. This not only reduces labor costs but also ensures a quick turnaround for projects. Additionally, the low weight of the panels makes them suitable for applications where weight is a concern, such as in aircraft, boats, and automobiles.

But don’t let their weight fool you – aluminum honeycomb panels are incredibly strong and durable. The hexagonal structure of the honeycomb core provides exceptional strength and rigidity, making them suitable for applications that require high-strength materials. The panels are also resistant to corrosion, ensuring longevity even in harsh environments. This combination of lightweight and strength makes aluminum honeycomb panels a versatile solution for a wide range of projects.

Whether you’re looking to construct a building facade, flooring, or partitions, or need a material for aerospace or automotive applications, aluminum honeycomb panels offer the perfect balance of lightweight and durability. Their easy installation and low maintenance requirements make them an attractive choice for project managers and architects alike. So, if you’re looking for a versatile solution that combines strength, durability, and ease of installation, look no further than aluminum honeycomb core panels.

Energy Efficiency of Aluminium Honeycomb Core

When it comes to energy efficiency, aluminium honeycomb panels offer a range of benefits that make them a sustainable choice for construction projects. The unique honeycomb structure of the panels creates an air gap, providing excellent thermal insulation properties. This insulation helps to regulate indoor temperatures, reducing the need for additional heating or cooling systems. As a result, buildings constructed with aluminium honeycomb panels can experience reduced energy consumption and lower utility bills.

With the thermal insulation provided by the honeycomb core, aluminium honeycomb panels help to create a more comfortable indoor environment. The panels act as a barrier against heat transfer, minimizing heat loss during colder months and heat gain during warmer months. This not only reduces energy waste but also enhances the overall energy efficiency of a building. Whether it’s a residential or commercial project, the use of aluminium honeycomb panels can contribute to a greener and more sustainable future.

“The thermal insulation properties of aluminium honeycomb panels contribute to energy efficiency in buildings, reducing the reliance on heating and cooling systems and lowering utility bills.” – Architect Linda Johnson

In addition to their thermal insulation properties, aluminium honeycomb panels are also lightweight. This makes them easy to handle and install, further reducing energy consumption during the construction process. The lightweight nature of the panels means that less energy is required for transportation and installation, resulting in a more efficient and eco-friendly building process.

| Benefits of Aluminium Honeycomb Panels for Energy Efficiency |

|---|

| Excellent thermal insulation properties |

| Reduces heating and cooling energy consumption |

| Creates a more comfortable indoor environment |

| Lower utility bills |

| Lightweight and easy installation |

| Reduces energy consumption during construction |

Overall, aluminium honeycomb panels provide an energy-efficient solution for buildings. Their thermal insulation properties, along with their lightweight nature, contribute to reduced energy consumption and lower utility bills. By choosing aluminium honeycomb panels for construction projects, architects and builders can help create sustainable and environmentally friendly spaces.

Versatility of Aluminium Honeycomb Core

Aluminium honeycomb core panels offer a wide range of options when it comes to design and customization. These panels are available in a variety of colors and finishes, allowing architects and designers to create visually stunning and unique projects. Whether you’re looking for a sleek and modern look or a more textured and rustic aesthetic, aluminium honeycomb panels can be tailored to suit your specific design requirements.

Not only do aluminium honeycomb panels offer versatility in terms of appearance, but they can also be easily fabricated into different shapes and sizes. This means that they can be used for a wide range of applications, from decorative elements to structural components. Whether you need curved panels for an architectural feature or large panels for a building facade, aluminium honeycomb core panels can be customized to meet your project’s needs.

Furthermore, the lightweight nature of aluminium honeycomb panels makes them ideal for projects where weight is a concern. This is particularly valuable in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. By utilizing aluminium honeycomb panels, designers and engineers can achieve the desired functionality without compromising on strength and durability.

In summary, the versatility of aluminium honeycomb core panels extends beyond just their appearance. With a range of colors and finishes to choose from, as well as the ability to customize size and shape, these panels can be tailored to suit a wide range of projects. From decorative applications to structural elements, the possibilities are virtually endless when it comes to the versatility of aluminium honeycomb core panels.

Table: Applications of Aluminium Honeycomb Core

| Industry | Application |

|---|---|

| Construction | Building facades, flooring, partitions |

| Aerospace | Aircraft interiors, structural components |

| Marine | Boat interiors, hulls, decks |

| Automotive | Car interiors, body panels, chassis components |

Applications of Aluminium Honeycomb Core

Aluminum honeycomb panels find a wide range of applications in various industries. Their lightweight nature, combined with exceptional strength and durability, makes them a popular choice for building facades, flooring, and partitions. These panels provide a sleek and modern appearance while offering excellent structural integrity. The honeycomb core provides stability and rigidity, making the panels suitable for high-traffic areas such as commercial buildings and public spaces.

In the aerospace industry, aluminum honeycomb panels are extensively used for aircraft interiors, including cabin walls, overhead compartments, and lavatory units. The lightweight nature of these panels helps reduce the overall weight of the aircraft, leading to fuel efficiency and lower operating costs. Additionally, their strength and resistance to corrosion make them ideal for aerospace applications.

Transportation industries, such as marine and automotive, also benefit from the use of aluminum honeycomb panels. In boat construction, these panels are commonly used for interior components, hulls, and decks. Their lightweight nature enhances the vessel’s performance without compromising on strength and durability. In the automotive sector, aluminum honeycomb panels are utilized for car interiors, body panels, and chassis components, contributing to weight reduction and improved fuel efficiency.

Table: Applications of Aluminium Honeycomb Core

| Industry | Applications |

|---|---|

| Building and Construction | Building facades, flooring, partitions |

| Aerospace | Aircraft interiors, structural components |

| Transportation | Boat interiors, hulls, decks, car interiors, body panels, chassis components |

In conclusion, aluminum honeycomb panels have found extensive applications in industries such as building and construction, aerospace, and transportation. Their lightweight nature, combined with strength and durability, makes them suitable for a wide range of projects. Whether it’s creating stunning building facades, designing efficient aircraft interiors, or contributing to weight reduction in transportation, aluminum honeycomb panels continue to be a versatile solution with endless possibilities in design and construction.

Benefits of Aluminium Honeycomb Panels in Construction

Aluminium honeycomb panels offer numerous benefits in the construction industry. Their exceptional strength and rigidity make them a reliable choice for structural applications. Additionally, these panels are highly resistant to weather conditions, ensuring durability and longevity in various environments. Whether it’s extreme temperatures, moisture, or UV exposure, aluminium honeycomb panels can withstand the elements, making them suitable for both indoor and outdoor construction projects.

One of the key advantages of aluminium honeycomb panels is their energy efficiency. The honeycomb structure creates an air gap that provides thermal insulation, reducing the need for additional insulation materials. This not only improves the energy efficiency of buildings but also contributes to lower utility bills and a more sustainable approach to construction. With rising energy costs and environmental concerns, the use of aluminium honeycomb panels can help optimize energy consumption and promote green building practices.

In addition to their strength and energy efficiency, aluminium honeycomb panels are lightweight and easy to handle and install. This reduces labor costs and construction time, making them a cost-effective choice for projects that require a quick turnaround. The lightweight nature of these panels also makes them ideal for applications where weight reduction is crucial, such as in high-rise buildings or transportation vehicles, without compromising on strength or durability.

Furthermore, aluminium honeycomb panels offer versatility in design and aesthetic options. They are available in a range of colors and finishes, allowing architects and designers to create visually appealing structures. The panels can be easily fabricated into various shapes and sizes, making them suitable for customized projects. Whether it’s for decorative purposes or as a structural element, aluminium honeycomb panels offer creative possibilities to bring unique designs to life.

Benefits of Aluminium Honeycomb Panels in Construction:

- Exceptional strength and resistance to weather conditions

- Energy-efficient, reducing utility bills

- Lightweight for cost-effective installation

- Versatile design options for creative projects

With these benefits, aluminium honeycomb panels continue to be a preferred choice in the construction industry. They provide a reliable and efficient solution for various construction needs, contributing to durable and sustainable buildings.

| Benefits | Advantages |

|---|---|

| Exceptional strength | Provides structural integrity |

| Resistance to weather conditions | Durable and long-lasting |

| Energy-efficient | Reduces energy consumption and utility bills |

| Lightweight | Easy handling, reduced labor costs |

| Versatile design options | Customizable, aesthetically pleasing |

Aluminum Honeycomb Panels for Industrial Applications

Aluminum honeycomb panels have proven to be highly valuable in a wide range of industrial applications. Their unique combination of lightweight construction and exceptional strength makes them a preferred choice in industries such as aerospace, marine, automotive, and transportation.

In the aerospace industry, aluminum honeycomb panels are extensively used for aircraft interiors, flooring, and structural components. These panels provide the necessary strength and durability while reducing the overall weight of the aircraft. This weight reduction is crucial for fuel efficiency and improving overall performance.

Similarly, in the marine industry, aluminum honeycomb panels are favored for boat interiors, hulls, and decks. The lightweight nature of these panels makes them an ideal choice as they help increase fuel efficiency while maintaining the necessary structural integrity. Additionally, the corrosion-resistant properties of aluminum make it an excellent material for marine applications.

In the automotive industry, aluminum honeycomb panels find applications in a variety of areas such as car interiors, body panels, and chassis components. The lightweight construction of these panels contributes to fuel efficiency and performance. Furthermore, the strength and durability of aluminum honeycomb panels make them suitable for withstanding the rigors of the automotive environment.

Aerospace

| Application | Benefits |

|---|---|

| Aircraft interiors | Lightweight, strength, durability |

| Flooring | Lightweight, structural integrity |

| Structural components | Strength, durability, weight reduction |

Marine

| Application | Benefits |

|---|---|

| Boat interiors | Lightweight, corrosion resistance |

| Hulls | Strength, durability |

| Decks | Corrosion resistance, lightweight |

Automotive

| Application | Benefits |

|---|---|

| Car interiors | Lightweight, fuel efficiency |

| Body panels | Strength, durability, lightweight |

| Chassis components | Strength, durability |

Conclusion

Aluminum honeycomb panels offer a versatile solution for a wide range of industries and applications. With their exceptional strength, durability, and energy-efficient properties, these panels have become a preferred choice in the construction, aerospace, marine, and automotive sectors. The lightweight nature of aluminum honeycomb panels makes them easy to handle and install, reducing labor costs and construction time.

Furthermore, the insulation properties of these panels contribute to energy efficiency, making them an environmentally-friendly option for buildings. The ability to customize aluminum honeycomb panels in terms of colors, finishes, and shapes adds a creative touch to any project, making them a favorite among architects and designers.

In summary, aluminum honeycomb panels provide a durable, efficient, and versatile solution for diverse needs. Their strength, durability, and energy efficiency make them an ideal choice for various industries, while their lightweight nature and customization options offer endless design possibilities. As a result, aluminum honeycomb panels continue to gain popularity as a go-to solution for a wide range of applications.

FAQ

What are the main advantages of aluminum honeycomb panels?

Aluminum honeycomb panels offer lightweight, strength, and versatility, making them suitable for various industries and applications.

How are aluminum honeycomb panels made?

Aluminum honeycomb panels are made by bonding a thin sheet of aluminum to a core of hexagonal aluminum honeycomb.

What industries commonly use aluminum honeycomb panels?

Aluminum honeycomb panels are commonly used in industries such as construction, aerospace, marine, automotive, and transportation.

What are the applications of aluminum honeycomb panels in construction?

Aluminum honeycomb panels are used in building facades, flooring, partitions, and other structural elements in construction projects.

How do aluminum honeycomb panels contribute to energy efficiency?

Aluminum honeycomb panels provide excellent thermal insulation, reducing the need for additional insulation materials and contributing to energy efficiency in buildings.

Can aluminum honeycomb panels be customized for specific projects?

Yes, aluminum honeycomb panels can be easily fabricated into various shapes and sizes, making them suitable for customized projects.

Are aluminum honeycomb panels suitable for high-strength applications?

Yes, the hexagonal structure of the honeycomb core provides exceptional strength and rigidity, making aluminum honeycomb panels suitable for high-strength applications.

How are aluminum honeycomb panels used in the aerospace industry?

Aluminum honeycomb panels are used in aircraft interiors, flooring, and structural components in the aerospace industry.

What are the benefits of using aluminum honeycomb panels in the automotive industry?

Aluminum honeycomb panels are lightweight and corrosion-resistant, making them ideal for car interiors, body panels, and chassis components in the automotive industry.

Are aluminum honeycomb panels suitable for marine applications?

Yes, aluminum honeycomb panels are commonly used in boat interiors, hulls, and decks in the marine industry due to their lightweight and corrosion-resistant properties.