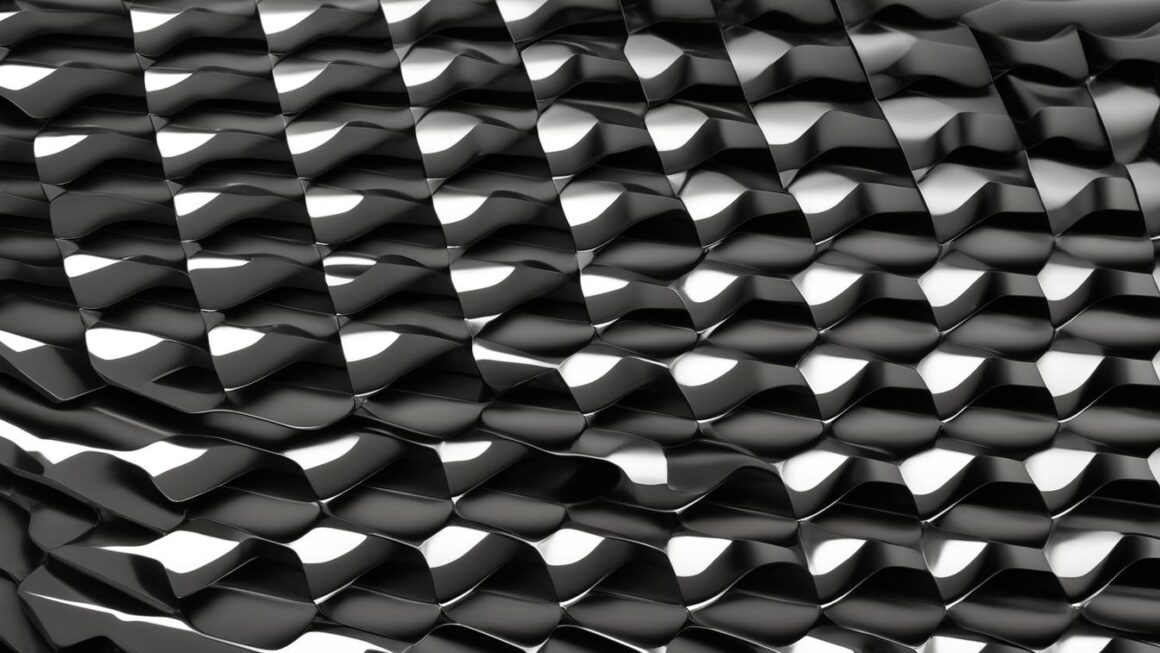

Carbon fiber honeycomb sandwich panels are revolutionizing various industries with their lightweight and durable characteristics. These panels, composed of carbon fiber prepreg layers enclosing a honeycomb core, offer exceptional strength, stiffness, and longevity. With their high strength-to-weight ratio, excellent thermal insulation, and corrosion resistance, carbon fiber honeycomb sandwich panels provide a reliable and long-lasting construction material.

Key Takeaways:

- Carbon fiber honeycomb sandwich panels are lightweight and durable.

- They offer exceptional strength, stiffness, and thermal insulation.

- These panels are corrosion-resistant and provide long-lasting performance.

- Customization options include size, shape, and surface finish.

- They find applications in aerospace, automotive, and construction industries.

Carbon Fiber Honeycomb Sandwich Panel Specifications and Customization

Carbon fiber honeycomb sandwich panels offer a wide range of specifications and customization options to meet the specific requirements of various applications. These panels can be customized in terms of thickness, size, and even shape, allowing for a tailored solution for each project.

The thickness of carbon fiber honeycomb sandwich panels can range from 0.2mm to 30mm, with the option for custom thicknesses based on specific load-bearing and structural needs. Additionally, the standard sizes for these panels are 400*500mm and 200*300mm, but they can also be customized to sizes such as 500*600mm, providing flexibility in design and application.

In terms of customization, carbon fiber honeycomb sandwich panels can be CNC cut based on specific drawings and design requirements. This ensures precise shaping and fitting, making them suitable for various intricate projects. Whether it’s a panel for aerospace, automotive, or construction applications, these panels can be tailored to meet the desired specifications.

Overall, the specifications and customization options of carbon fiber honeycomb sandwich panels make them a versatile choice for a wide range of industries. The ability to choose the right thickness, size, and shape allows for optimized performance and functionality in any given application.

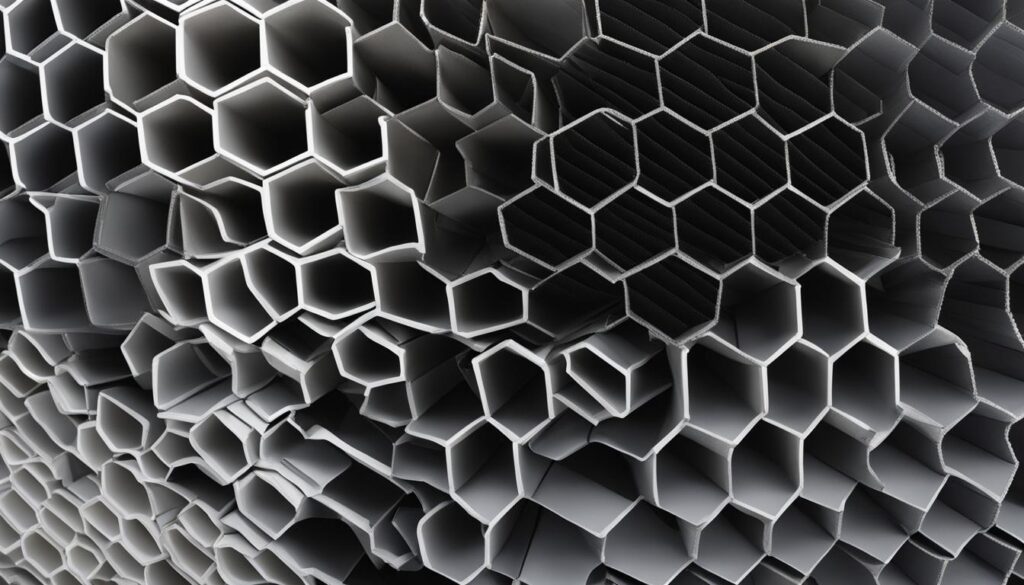

Carbon Fiber Honeycomb Sandwich Panel Core Material Options

When it comes to carbon fiber honeycomb sandwich panels, the choice of core material plays a crucial role in determining their performance and characteristics. Various core materials are available, each offering unique properties and advantages for specific applications.

One commonly used core material is PVC/PMI foam, which provides optimal stiffness-to-weight ratio and excellent thermal insulation. Aluminum honeycomb core, on the other hand, offers high strength and corrosion resistance, making it suitable for demanding environments. Aramid paper honeycomb core is known for its moisture resistance and flame retardancy, while PP honeycomb core provides lightweight yet robust construction.

Balsa wood core is another popular option, offering a combination of lightweight design and exceptional strength. This natural wood core provides excellent thermal insulation and has been used in various industries, including aerospace and marine.

Carbon Fiber Honeycomb Sandwich Panel Core Material Options:

| Core Material | Properties |

|---|---|

| PVC/PMI foam | Optimal stiffness-to-weight ratio, excellent thermal insulation |

| Aluminum honeycomb | High strength, corrosion resistance |

| Aramid paper honeycomb | Moisture resistance, flame retardancy |

| PP honeycomb | Lightweight, robust construction |

| Balsa wood | Lightweight, exceptional strength, thermal insulation |

The choice of core material depends on the desired performance, application requirements, and industry specifications. By selecting the appropriate core material, carbon fiber honeycomb sandwich panels can be customized to meet specific needs, ensuring optimal performance and durability.

Benefits of Carbon Fiber Honeycomb Sandwich Panels in Various Industries

Carbon fiber honeycomb sandwich panels offer a plethora of benefits that make them highly advantageous for use in various industries. These lightweight panels have revolutionized the aerospace, automotive, marine, construction, and industrial sectors with their exceptional properties. Let’s explore the remarkable advantages that carbon fiber honeycomb sandwich panels bring to these industries:

Fuel Efficiency and Lightweight Design

One of the key benefits of carbon fiber honeycomb sandwich panels is their lightweight nature. This attribute makes them particularly valuable in the aerospace and automotive industries, where weight reduction is crucial. The panels’ low weight contributes to increased fuel efficiency in aircraft, improving overall performance and reducing operating costs. In the automotive sector, carbon fiber honeycomb sandwich panels enable the production of lightweight components, enhancing fuel economy and reducing environmental impact.

High Strength-to-Weight Ratio

Despite their lightness, carbon fiber honeycomb sandwich panels exhibit an exceptional strength-to-weight ratio. This characteristic ensures structural integrity and load-bearing capabilities, making them ideal for applications that require durability and high performance. The use of carbon fiber skins and a honeycomb core results in panels that can withstand significant mechanical stresses while maintaining their integrity.

Thermal Insulation and Temperature Control

Carbon fiber honeycomb sandwich panels possess excellent thermal insulation properties, making them suitable for applications that require temperature control. These panels effectively retain heat, providing insulation against extreme temperatures. This attribute is particularly valuable in industries such as aerospace, automotive, and electronics, where temperature variations can impact performance or pose a risk to sensitive components.

Corrosion Resistance and Durability

Another significant advantage of carbon fiber honeycomb sandwich panels is their exceptional corrosion resistance and durability. These panels can withstand harsh environmental conditions, including exposure to moisture, chemicals, and saltwater. This makes them highly suitable for industries such as marine, construction, and industrial automation, where resistance to corrosion and long-lasting performance are critical requirements.

Summary

Carbon fiber honeycomb sandwich panels offer a wide range of benefits that make them an attractive choice for various industries. Their lightweight design contributes to fuel efficiency in aerospace and automotive applications, while their high strength-to-weight ratio ensures structural integrity. The panels’ thermal insulation properties provide temperature control, while their corrosion resistance and durability make them suitable for demanding environments. Overall, carbon fiber honeycomb sandwich panels offer a reliable and efficient solution that combines lightweight construction with robust performance.

| Industry | Benefits |

|---|---|

| Aerospace | Fuel efficiency, lightweight design, high strength, thermal insulation |

| Automotive | Fuel economy, lightweight components, temperature control |

| Marine | Corrosion resistance, durability, lightweight construction |

| Construction | Lightweight paneling, structural components, durability |

| Industrial | Corrosion resistance, durability, lightweight automation solutions |

Applications of Carbon Fiber Honeycomb Sandwich Panels

Carbon fiber honeycomb sandwich panels have become a versatile solution with applications in various industries. The lightweight and durable nature of these panels make them ideal for a wide range of uses. Let’s explore some of the key applications of carbon fiber honeycomb sandwich panels:

Aerospace Industry

In the aerospace industry, carbon fiber honeycomb sandwich panels are widely used for aircraft interiors, general purpose aviation panels, and unmanned aerial vehicles (UAVs). These panels offer a lightweight alternative to traditional materials, reducing weight and enhancing fuel efficiency. Additionally, their high strength-to-weight ratio ensures structural integrity, making them suitable for critical components.

Automotive Industry

The automotive industry utilizes carbon fiber honeycomb sandwich panels for interior design and lightweight components. These panels provide an excellent solution for reducing the weight of vehicles, improving fuel economy, and optimizing performance. The high strength and durability of carbon fiber honeycomb sandwich panels make them a preferred choice for automotive manufacturers.

Marine Industry

In the marine industry, carbon fiber honeycomb sandwich panels find applications in paneling and structural components. Their lightweight nature helps in achieving optimum performance while maintaining stability. These panels also offer corrosion resistance and durability, making them suitable for demanding marine environments.

Construction Industry

Carbon fiber honeycomb sandwich panels are increasingly used in the construction industry for various purposes. They can be applied in paneling, interior design, and structural components. These panels provide a lightweight alternative to traditional construction materials, reducing the overall weight of structures without compromising strength and durability.

| Industry | Applications |

|---|---|

| Aerospace | Aircraft interiors, general purpose aviation panels, UAVs |

| Automotive | Interior design, lightweight components |

| Marine | Paneling, structural components |

| Construction | Paneling, interior design, structural components |

Weave and Surface Finish Options for Carbon Fiber Honeycomb Sandwich Panels

When it comes to carbon fiber honeycomb sandwich panels, customization plays a crucial role in meeting specific design preferences. One aspect of customization is the weave options available for these panels. Weave patterns such as plain, twill, hexagonal, satin, and hybrid options like carbon-fiberglass or carbon-Kevlar provide different aesthetics and performance characteristics. Whether you’re looking for a classic look or a unique design, the variety of weave options allows for creative freedom in creating visually appealing structures.

In addition to weave options, the surface finish of carbon fiber honeycomb sandwich panels can also be customized. The choice of surface finish, whether glossy, matte, or color painting, depends on the desired appearance and functional requirements of the project. A glossy finish can give a sleek and polished look, while a matte finish can provide a more subtle and sophisticated appearance. The option to add color painting finishes further enhances the customization possibilities, allowing panels to match specific branding or design elements.

By offering both weave and surface finish options, carbon fiber honeycomb sandwich panels can be tailored to suit a wide range of applications. Whether it’s for the aerospace industry, automotive sector, or any other industry where lightweight, high-strength materials are required, these customization options ensure that the panels meet both functional and aesthetic needs. The ability to create unique designs and finishes sets carbon fiber honeycomb sandwich panels apart as a versatile and visually appealing construction material.

| Weave Options | Surface Finish Options |

|---|---|

| Plain | Glossy |

| Twill | Matte |

| Hexagonal | Color Painting |

| Satin | |

| Hybrid (Carbon-Fiberglass or Carbon-Kevlar) |

Table: Weave and Surface Finish Options for Carbon Fiber Honeycomb Sandwich Panels

Carbon Fiber Honeycomb Sandwich Panel Benefits – Lightweight, High Strength, and Durability

Carbon fiber honeycomb sandwich panels offer several key benefits that make them a highly sought-after solution in various industries. One of the most significant advantages of these panels is their lightweight nature. Due to the carbon fiber skins and honeycomb core combination, they provide exceptional strength-to-weight ratio, allowing for significant weight reduction in applications where weight is a critical factor. This makes carbon fiber honeycomb sandwich panels ideal for industries such as aerospace and automotive, where fuel efficiency and improved performance are paramount.

Despite their low weight, carbon fiber honeycomb sandwich panels exhibit remarkable high strength. The honeycomb core structure, along with the carbon fiber skins, provides excellent load-bearing capabilities and structural integrity. This high strength allows these panels to withstand substantial external forces, making them suitable for demanding applications in industries such as construction, marine, and industrial automation.

Furthermore, carbon fiber honeycomb sandwich panels offer exceptional durability. The carbon fiber skins provide resistance to corrosion, ensuring that the panels can withstand harsh environments without degradation. This durability makes carbon fiber honeycomb sandwich panels a reliable long-term solution, reducing maintenance and replacement costs over time.

These panels offer a combination of lightweight construction, high strength, and durability that makes them an optimal choice for various applications.

Table: Comparison of Carbon Fiber Honeycomb Sandwich Panels with Traditional Construction Materials

| Properties | Carbon Fiber Honeycomb Sandwich Panels | Traditional Construction Materials |

|---|---|---|

| Weight | Lightweight | Heavier |

| Strength | High | Lower |

| Durability | Excellent | Prone to corrosion and deterioration |

| Thermal Insulation | Good | Varies depending on material |

| Customization | Highly versatile | Limitations in design flexibility |

In comparison to traditional construction materials, carbon fiber honeycomb sandwich panels offer a range of advantages. They are significantly lighter in weight, providing fuel efficiency in aerospace and improving overall performance in automotive applications. The high strength of these panels ensures structural integrity while reducing the overall weight of the construction. Additionally, carbon fiber honeycomb sandwich panels exhibit excellent thermal insulation properties, making them suitable for applications that require temperature control.

In summary, carbon fiber honeycomb sandwich panels offer a compelling combination of lightweight design, high strength, and durability. These panels are a versatile and reliable solution for various industries, where their exceptional performance and long-lasting characteristics provide significant advantages.

Customization Options for Carbon Fiber Honeycomb Sandwich Panels

Carbon fiber honeycomb sandwich panels offer a wide range of customization options to meet the specific requirements of different projects. From size and shape to thickness and surface finish, these panels can be tailored to fit various applications.

When it comes to size and shape, carbon fiber honeycomb sandwich panels can be customized to match specific dimensions. Whether you need rectangular panels or more complex shapes, such as curved or angled panels, the size and shape can be adjusted to ensure a perfect fit.

Thickness is another factor that can be customized. Depending on the load-bearing and structural needs of the project, the thickness of the panels can be chosen accordingly. This customization allows for optimal performance and ensures that the panels meet the required strength and durability standards.

In addition to size, shape, and thickness, the surface finish of carbon fiber honeycomb sandwich panels can also be customized. Different surface finishes, such as glossy or matte, can be chosen depending on the desired appearance and functional requirements of the project. The surface finish not only enhances the aesthetics but also provides protection against environmental factors and enhances the overall durability of the panels.

Customization Options for Carbon Fiber Honeycomb Sandwich Panels:

| Customization Option | Description |

|---|---|

| Size and Shape | Tailored to fit specific dimensions, including rectangular and complex shapes. |

| Thickness | Customizable based on load-bearing and structural requirements. |

| Surface Finish | Options include glossy, matte, and other finishes for enhanced aesthetics and protection. |

With such extensive customization options, carbon fiber honeycomb sandwich panels can be optimized for each unique application, ensuring the perfect combination of performance, functionality, and visual appeal.

Carbon Fiber Honeycomb Sandwich Panel Usage in Construction, Aerospace, and Automotive Industries

Carbon fiber honeycomb sandwich panels have seen significant utilization in the construction, aerospace, and automotive industries due to their unique combination of lightweight properties and durability. In the construction sector, these panels find extensive application in paneling, interior design, and structural components. Their lightweight nature allows for easier installation and reduces the overall weight of buildings, while their high strength ensures structural integrity and longevity.

In the aerospace industry, carbon fiber honeycomb sandwich panels are widely used for aircraft interiors, aviation panels, and unmanned aerial vehicles (UAVs). The lightweight nature of these panels contributes to fuel efficiency and improved performance, making them an ideal choice for aerospace applications. Additionally, their high strength-to-weight ratio provides enhanced structural integrity and safety.

The automotive industry also benefits from the advantages offered by carbon fiber honeycomb sandwich panels. These panels are utilized for lightweight components, such as body panels and interior design elements, contributing to improved fuel economy and overall vehicle performance. The lightweight nature of these panels also allows for better handling and maneuverability of vehicles.

In summary, carbon fiber honeycomb sandwich panels have found widespread usage in the construction, aerospace, and automotive industries. Their lightweight properties, coupled with exceptional strength and durability, make them an ideal choice for various applications. These panels contribute to the overall efficiency, performance, and sustainability of different industries due to their ability to reduce weight while maintaining structural integrity and longevity.

Conclusion

The carbon fiber honeycomb sandwich panel is a lightweight panel that offers a durable solution for various industries. With its high strength-to-weight ratio and excellent thermal insulation properties, this panel provides optimal performance in demanding environments. Its corrosion resistance ensures long-lasting durability, making it a reliable choice for construction, aerospace, and automotive applications.

Customization options such as size, shape, and surface finish allow for tailored solutions to meet specific project requirements. This versatility makes the carbon fiber honeycomb sandwich panel an efficient construction material that combines lightweight design with high strength and durability.

Overall, the carbon fiber honeycomb sandwich panel is a valuable solution for industries seeking a lightweight yet robust construction material. Its durability, customization options, and excellent performance characteristics make it a reliable choice for those looking for a long-lasting and efficient solution.

FAQ

What are carbon fiber honeycomb sandwich panels made of?

Carbon fiber honeycomb sandwich panels are made by sandwiching a honeycomb core between layers of carbon fiber prepreg.

What are the standard sizes for carbon fiber honeycomb sandwich panels?

The standard sizes for carbon fiber honeycomb sandwich panels are 400*500mm and 200*300mm, but they can also be customized to sizes such as 500*600mm.

What are the core material options for carbon fiber honeycomb sandwich panels?

Some core material options for carbon fiber honeycomb sandwich panels include PVC/PMI foam core, aluminum honeycomb core, aramid paper honeycomb core, PP honeycomb core, and wood core such as balsa wood.

What are the benefits of carbon fiber honeycomb sandwich panels in various industries?

Carbon fiber honeycomb sandwich panels offer lightweight construction, high strength, thermal insulation, corrosion resistance, and durability, making them suitable for applications in industries such as aerospace, automotive, marine, and construction.

What are the applications of carbon fiber honeycomb sandwich panels?

Carbon fiber honeycomb sandwich panels are used in industries such as aerospace (aircraft interiors, aviation panels, UAVs), automotive (lightweight components, interior design), marine (paneling), and construction (paneling, interior design, structural components).

What weave and surface finish options are available for carbon fiber honeycomb sandwich panels?

Weave options include plain, twill, hexagonal, satin, and hybrid carbon-fiberglass or carbon-Kevlar options. Surface finish options include glossy, matte, and color painting finishes.

What are the benefits of carbon fiber honeycomb sandwich panels?

Carbon fiber honeycomb sandwich panels are lightweight, yet exhibit high strength and durability. They offer fuel efficiency, structural integrity, thermal insulation, corrosion resistance, and long-lasting performance.

What customization options are available for carbon fiber honeycomb sandwich panels?

Carbon fiber honeycomb sandwich panels can be customized in terms of size, shape, thickness, and surface finish to meet specific project requirements.

In which industries are carbon fiber honeycomb sandwich panels commonly used?

Carbon fiber honeycomb sandwich panels are commonly used in industries such as construction, aerospace, and automotive due to their lightweight yet durable properties.