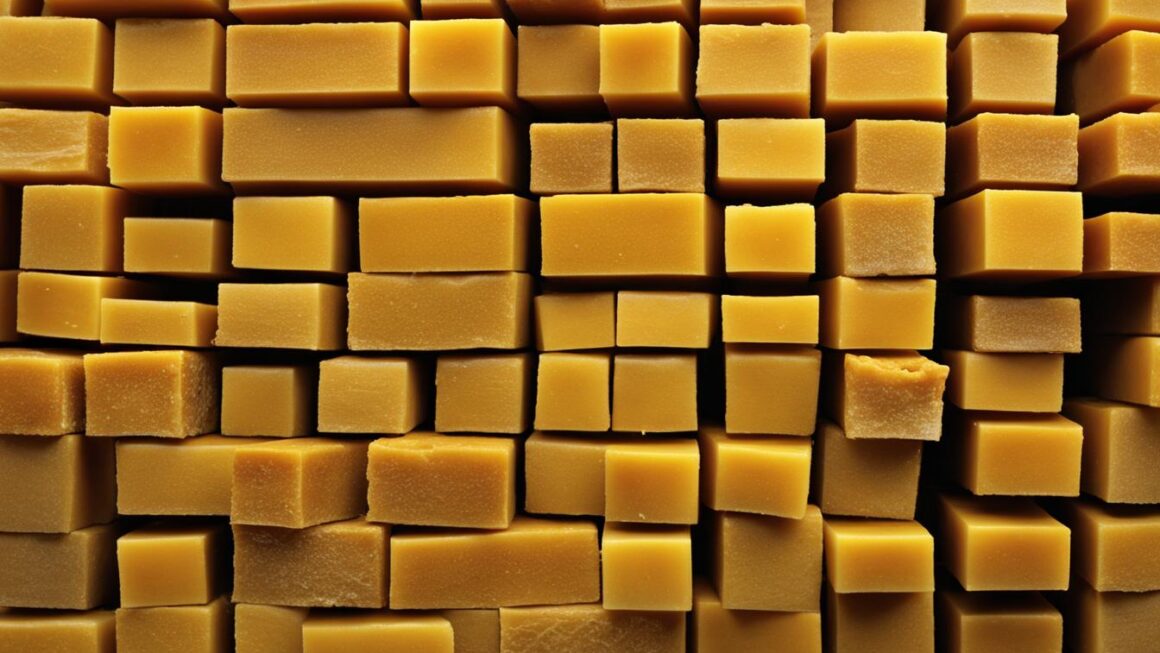

Beeswax filtering is an essential process that ensures the purity and quality of this versatile substance. Whether you are a beekeeper or a DIY enthusiast, understanding the different beeswax filtering techniques is crucial for obtaining clean and refined beeswax for your projects.

Key Takeaways:

- Filtering beeswax is vital for removing impurities and ensuring a high-quality end product.

- There are various beeswax filtering methods available, including sedimentary filtering, gravity filtering, water bath method, double boiler method, and crockpot method.

- Each filtering technique has its advantages and is suitable for different scales of operations and desired levels of purity.

- Experimenting with different filtering methods can help you find the one that works best for your needs and preferences.

- Mastering the art of beeswax filtering will enhance the appearance, performance, and versatility of this valuable natural material.

The Importance of Beeswax Filtering

Filtering beeswax is a crucial step in the production process to ensure the purity and quality of this versatile substance. By removing impurities such as bee parts, pollen, and hive debris, filtering improves the appearance, performance, and overall quality of the beeswax. This is especially important for applications where purity is a priority, such as in cosmetics and candle making.

Purifying beeswax through effective filtering techniques is essential to achieve the desired results. By following best practices for filtering beeswax, you can ensure that your final product is free from unwanted contaminants. Proper filtration not only enhances the aesthetic appeal but also contributes to the functionality and longevity of beeswax-based products.

Whether you are a beekeeper or a DIY enthusiast, understanding the importance of beeswax filtering is key to obtaining high-quality beeswax. The next sections will explore different filtering methods and provide step-by-step instructions for each technique, allowing you to choose and implement the method that best suits your needs.

Best Practices for Filtering Beeswax:

- Ensure that your filtering equipment is clean and free from debris before starting the process.

- Use a fine mesh or filter medium that can effectively trap impurities without hindering the flow of wax.

- Allow sufficient time for the beeswax to cool and solidify after filtering to facilitate easy removal of impurities.

- Regularly clean and maintain your filtering equipment to prevent the buildup of residue, which can affect the quality of the filtered wax.

Quote:

Proper beeswax filtering is the foundation of producing high-quality beeswax products. By removing impurities, we ensure that our customers receive the purest and most reliable beeswax for their creative endeavors.” – Beekeeping expert, Jane Smith

| Filtering Method | Key Benefits |

|---|---|

| Sedimentary Filtering | Simple and cost-effective method suitable for small-scale filtering. |

| Gravity Filtering | Provides thorough purification and is ideal for larger-scale operations. |

| Water Bath Method | A versatile and easy-to-perform method suitable for small quantities of wax. |

| Double Boiler Method | Ensures controlled and safe melting of beeswax for optimal purity. |

| Crockpot (Slow Cooker) Method | Convenient and hands-off approach for cleaning larger quantities of beeswax. |

Sedimentary Filtering

One of the effective methods for filtering beeswax is sedimentary filtering. This technique is known for its simplicity and cost-effectiveness, making it suitable for small-scale operations. Sedimentary filtering helps remove larger impurities and debris from raw beeswax, resulting in cleaner and purer wax for various applications.

To perform sedimentary filtering, start by melting the beeswax in a double boiler or a heat-resistant container. Allow the wax to cool slowly, and as it cools, the impurities will settle at the bottom. Once the wax has solidified, carefully scrape off the impurities that have accumulated at the bottom using a spoon or a knife.

This method relies on gravity to separate the impurities from the beeswax. It is important to note that sedimentary filtering may not completely remove all impurities, especially smaller particles. For a more thorough purification, other filtering techniques such as gravity filtering or water bath method can be used in combination with sedimentary filtering.

Table: Sedimentary Filtering Instructions

| Steps | Equipment Needed |

|---|---|

| Melt the beeswax in a double boiler or a heat-resistant container | Double boiler or heat-resistant container |

| Allow the wax to cool slowly | None |

| Scrape off the impurities that have settled at the bottom | Spoon or knife |

“Sedimentary filtering is a simple and accessible method for small-scale beeswax filtering. It helps remove larger impurities, ensuring cleaner wax for various applications.” – Beekeeping expert

While sedimentary filtering is an effective method for initial purification, it is important to note that further filtering may be necessary, depending on the desired level of purity. Experimentation with different filtering methods can help find the best combination for clean beeswax production.

Gravity Filtering: An Effective Beeswax Filtering Process

Gravity filtering is a refined technique that offers a thorough purification process for beeswax. This method utilizes the force of gravity and a filtering medium to separate impurities from the melted wax, resulting in cleaner and higher quality beeswax.

The gravity filtering process involves pouring the melted beeswax into a filter medium, such as a pollen extractor or a mesh sieve. The filter traps larger impurities, such as bee parts and debris, while allowing the clean wax to flow through. This method ensures that the beeswax is thoroughly purified, making it suitable for various applications like candle making and cosmetics.

One of the key advantages of gravity filtering is its ability to handle larger-scale operations. Whether you are processing a small batch or a larger quantity of beeswax, this method can be easily adapted to accommodate your needs. Additionally, gravity filtering helps achieve a consistent and uniform filtration, resulting in a more refined end product.

The Gravity Filtering Process

- Melt the beeswax in a suitable container, ensuring it reaches a liquid state.

- Place a filter medium, such as a pollen extractor or a mesh sieve, over a clean container.

- Pour the melted beeswax into the filter medium, allowing it to pass through while trapping impurities.

- Allow the filtered wax to flow into the clean container, leaving behind the impurities.

- Repeat the process if necessary, ensuring a thorough filtration.

By utilizing gravity and a filtering medium, the gravity filtering method offers an effective way to separate impurities from beeswax. It is a versatile technique that can be adapted to different scales of operations. Incorporating gravity filtering into your beeswax filtering process will help you achieve a higher level of purity and enhance the overall quality of your beeswax products.

| Advantages of Gravity Filtering | Considerations |

|---|---|

| Thorough purification of beeswax | Requires a suitable filter medium |

| Handles larger-scale operations | May require multiple filtration cycles |

| Uniform and consistent filtration | Filter maintenance and cleaning |

Gravity filtering provides a reliable and efficient method for purifying beeswax. By harnessing the force of gravity, impurities can be effectively separated from the melted wax, resulting in a higher quality end product.

Water Bath Method

The water bath method is a popular and easy technique for cleaning beeswax. It involves melting the wax in water, allowing the impurities to separate and sink to the bottom, and then carefully pouring off the clean wax. Let’s dive into the step-by-step process of using the water bath method to clean your beeswax.

Gather Your Supplies

- A heat-resistant container

- Raw beeswax

- Pot with water

- Stove or heat source

- Strainer or cheesecloth

- Heat-resistant gloves or pot holders

The Cleaning Process

1. Cut the raw beeswax into small chunks or shavings to speed up the melting process.

2. Fill a pot with water and place it on the stove or heat source.

3. Place the heat-resistant container with the raw beeswax into the pot of water, creating a double boiler setup.

4. Heat the water on low to medium heat, gently melting the beeswax. Stir occasionally to ensure even melting.

5. As the beeswax melts, impurities will separate and sink to the bottom of the container.

6. Once the wax is completely melted and the impurities have settled, carefully pour off the clean wax from the top, leaving the impurities behind.

7. For a final filtration, strain the melted wax through a strainer or cheesecloth to catch any remaining debris.

8. Allow the cleaned beeswax to cool and solidify before using it for your desired projects.

Benefits of the Water Bath Method

The water bath method offers a simple and accessible way to clean beeswax, making it suitable for small-scale operations or DIY enthusiasts. It requires minimal equipment and can be performed with household items. Additionally, this method effectively removes impurities, ensuring a clean and high-quality beeswax for your projects.

| Pros | Cons |

|---|---|

| Easy and accessible method | Not suitable for large quantities of beeswax |

| Minimal equipment required | Requires careful handling of hot wax |

| Effective in removing impurities | May take longer compared to other methods |

| Produces high-quality beeswax |

The Double Boiler Method: A Safe and Controlled Approach to Beeswax Cleaning

When it comes to filtering beeswax, the double boiler method offers a reliable and efficient solution. This technique utilizes a double boiler setup to gently melt and clean beeswax, ensuring the removal of impurities while preserving its natural properties.

The double boiler method is particularly suitable for those who prioritize safety and precision in their beeswax filtering process. By using indirect heat and a water bath, the risk of overheating or scorching the wax is minimized, resulting in a higher quality end product.

To start the double boiler method, you will need a small pot and a larger pot filled with water. Place the smaller pot inside the larger pot, making sure it is stable. Add your raw beeswax to the smaller pot and set the heat to low. As the wax begins to melt, stir occasionally to ensure even heating.

Once the beeswax has completely melted, it is time to strain out any impurities. Position a fine-mesh strainer or a cheesecloth-lined colander over a clean container and carefully pour the melted wax through the strainer. The fine mesh or cheesecloth will trap any debris, leaving you with clean and purified beeswax.

The Benefits of the Double Boiler Method

The double boiler method offers several advantages for beeswax cleaning. Firstly, it allows for precise temperature control, preventing the wax from being exposed to high temperatures that may degrade its quality. Secondly, it ensures a thorough filtration process, effectively removing impurities for a cleaner final product. Lastly, this method is safe and easy to perform, making it accessible to both beginners and experienced beekeepers.

Using the double boiler method for beeswax filtering provides peace of mind, knowing that you are taking the necessary precautions to maintain the integrity and purity of the wax.

As with any filtering method, it is essential to follow best practices and monitor the process closely to achieve optimal results. By utilizing the double boiler method, you can confidently produce clean and high-quality beeswax for various applications, including candle making, cosmetics, and woodworking.

Summary

- The double boiler method offers a safe and controlled approach to cleaning beeswax.

- By using a double boiler setup, the wax can be gently melted and strained to remove impurities.

- Temperature control and thorough filtration are key benefits of the double boiler method.

- Following best practices will ensure clean and high-quality beeswax for various applications.

Crockpot (Slow Cooker) Method

The crockpot method is a convenient and efficient way to clean beeswax, especially when dealing with larger quantities. This method utilizes the gentle heat of a slow cooker to melt the beeswax and separate impurities, resulting in clean and purified wax ready for use.

To use the crockpot method, start by placing the raw beeswax in the slow cooker. Set the temperature to low or medium heat and allow the wax to melt slowly. As the wax melts, impurities will separate and sink to the bottom of the crockpot.

After a few hours, carefully remove the clean wax from the top, leaving behind any impurities that have settled. It’s important to be cautious while handling the hot wax and use a straining tool, such as a cheesecloth or a fine-mesh sieve, to strain out any remaining impurities.

Once the wax has been strained, it can be cooled and solidified for further use. The crockpot method is an ideal option for those who want a hands-off approach to beeswax cleaning, as it allows for easy monitoring and control of the melting process.

The crockpot method offers a convenient and manageable way to clean beeswax efficiently. It is particularly useful when working with larger quantities and provides a safe and controlled environment for melting and purifying the wax.

Experimenting with Filtering Methods

When it comes to filtering beeswax, there is no one-size-fits-all method. Each beekeeper or DIY enthusiast may have different needs and preferences, and it’s important to find the filtering method that works best for you. Experimenting with various techniques can help you discover the optimal approach for achieving the highest quality beeswax for your projects.

One method worth trying is the sedimentary filtering technique. This simple yet effective process involves melting the beeswax and allowing it to cool, allowing impurities to settle at the bottom. By carefully scraping off the impurities, you can achieve cleaner and purer wax. This method is cost-effective and accessible for small-scale filtering.

Another method to consider is gravity filtering, which provides a more refined and thorough purification. By pouring the melted beeswax through a filtering medium, like a pollen extractor, impurities are trapped while clean wax flows through. This technique is suitable for larger-scale operations and can result in higher purity levels.

For those working with smaller quantities of beeswax, the water bath method is a simple and versatile option. By melting the wax in water, you can allow impurities to separate and sink to the bottom. Carefully pouring off the clean wax can give you a purified end product. Similarly, the double boiler method provides controlled and safe melting of beeswax, followed by straining to remove impurities. This method allows for precise temperature control and can yield clean wax ready for use.

| Filtering Method | Benefits | Scale |

|---|---|---|

| Sedimentary Filtering | Cost-effective and accessible | Small-scale |

| Gravity Filtering | Thorough purification | Large-scale |

| Water Bath Method | Simple and versatile | Small-scale |

| Double Boiler Method | Precise temperature control | Small-scale |

Experiment with different filtering methods to refine your process and achieve the best results for your beeswax. By finding the method that works for you, you can ensure the highest quality and purity of this valuable natural material.

Conclusion

Filtering beeswax is a critical step in clean beeswax production, ensuring the removal of impurities and achieving a high-quality end product. By following the appropriate filtering methods and techniques discussed in this guide, you can transform raw beeswax into a refined and versatile natural material.

Whether you are a beekeeper or a DIY enthusiast, mastering the art of beeswax filtering is essential. It enhances the appearance and performance of beeswax, making it ideal for various applications, including cosmetics, candle making, and other crafts.

Experimentation plays a crucial role in finding the best beeswax filtering method for your specific needs. Consider factors such as the scale of your operation, the volume of beeswax being processed, and the level of purity desired. By fine-tuning your filtering process, you can achieve the highest quality beeswax for your projects.

Remember, the journey to clean beeswax production doesn’t end with filtering. To further enhance the quality, store your filtered beeswax in a cool, dry place away from direct sunlight. This will help maintain its purity and usability for future endeavors.

FAQ

Why is beeswax filtering important?

Beeswax filtering is important to remove impurities such as bee parts, pollen, and hive debris, improving the purity and quality of the beeswax.

What is sedimentary filtering?

Sedimentary filtering is a method that involves melting beeswax, allowing it to cool and separate from water, and then scraping off impurities that have settled at the bottom.

How does gravity filtering work?

Gravity filtering uses gravity and a filtering medium, such as a pollen extractor, to separate impurities from melted beeswax. The clean wax flows through the filter while impurities are trapped.

What is the water bath method?

The water bath method involves melting beeswax in water, allowing impurities to separate and sink to the bottom, and then carefully pouring off the clean wax.

How does the double boiler method work?

The double boiler method uses a setup of two pots, with the wax melting in the smaller pot inside a larger pot with water. The melted wax is then poured through a strainer to remove impurities.

What is the crockpot method?

The crockpot method involves melting beeswax in a crockpot on a low temperature setting, allowing impurities to separate and be strained out. It is ideal for larger quantities of wax.

Why should I experiment with filtering methods?

Experimenting with filtering methods allows you to find the one that works best for your specific needs and preferences, taking into account factors such as scale of operation and desired level of purity.

What are the benefits of filtering beeswax?

Filtering beeswax ensures a high level of purity, resulting in a refined end product that is suitable for various applications in cosmetics and candle making.