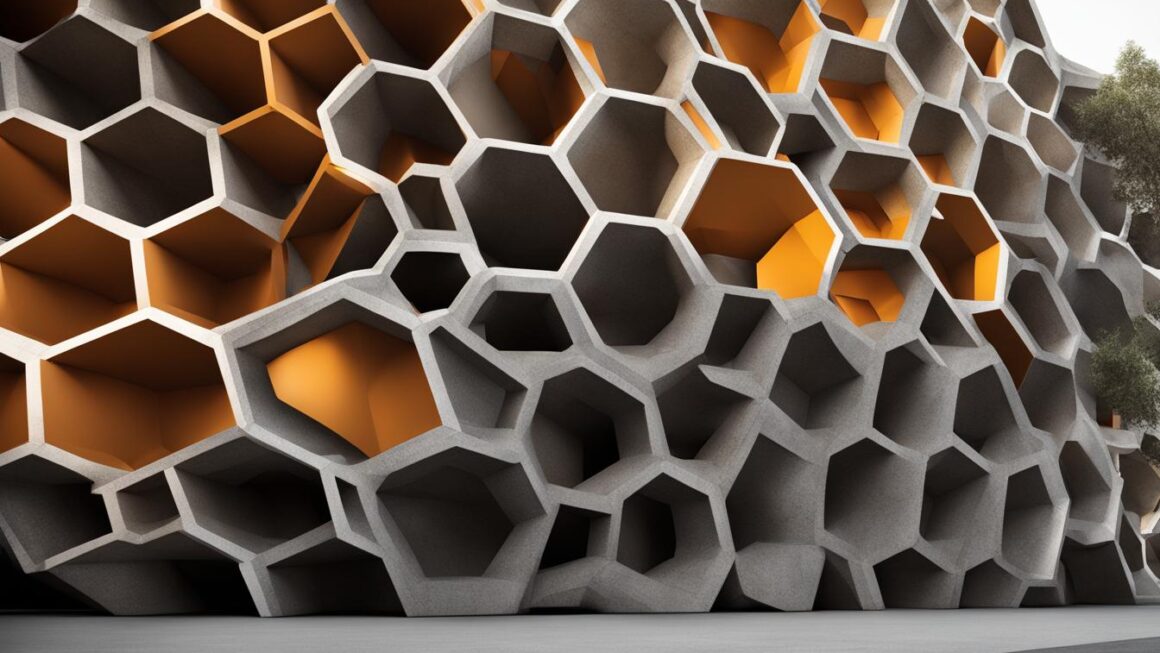

When it comes to building materials, honeycomb concrete offers a unique and innovative solution that combines strength, durability, and sustainability. This lightweight concrete, also known as cellular concrete or foam concrete, is characterized by its unique honeycomb structure, which consists of voids or cavities within the concrete matrix. These voids not only reduce the weight of the concrete but also provide excellent thermal insulation and acoustical properties.

Honeycomb concrete is created by incorporating air or gas bubbles into the concrete mixture, resulting in a cellular lightweight material that is both strong and eco-friendly. This technology has gained popularity in the construction industry due to its numerous benefits and applications.

Key Takeaways:

- Honeycomb concrete is a lightweight and eco-friendly building material.

- Its unique honeycomb structure provides excellent thermal insulation and acoustical properties.

- The technology behind honeycomb concrete involves incorporating air or gas bubbles into the concrete mixture.

- Honeycomb concrete offers strength, durability, and sustainability in construction projects.

- It has various applications, including interior partitions, cottages, factories, and more.

What is Honeycomb in Concrete?

Honeycomb in concrete refers to the formation of cavities due to poor compaction of the concrete. These cavities can occur close to the surface or internally. The main causes of honeycomb in concrete include lack of workability, inadequate vibration, reinforcement congestion, segregation, and inadequate cover to the reinforcements.

Poor compaction of the concrete can result in voids or gaps within the material, leading to honeycomb formation. This can happen when the concrete mixture is not properly mixed or when there is inadequate vibration during the pouring and settling process. Reinforcement congestion, where the steel bars are densely packed, can also contribute to the formation of honeycomb as it hinders the flow of concrete and causes uneven compaction.

To prevent honeycomb in concrete, it is important to ensure that the concrete mixture has good workability and is properly compacted. Adequate vibration should be applied during the pouring and settling process to ensure that the concrete fills all voids and gaps. Reinforcements should be properly spaced to allow for the easy flow of concrete. Additionally, adequate cover should be provided to protect the reinforcements and prevent segregation.

| Causes of Honeycomb in Concrete: |

|---|

| Lack of workability |

| Inadequate vibration |

| Reinforcement congestion |

| Segregation |

| Inadequate cover to the reinforcements |

Honeycomb in concrete can weaken the structure and affect its durability. These voids can lead to a reduction in structural capacity and can also create pathways for moisture and corrosion to damage the reinforcements. It is essential to address honeycomb in concrete during construction to ensure the integrity and longevity of the structure.

In the following sections, we will explore the causes and effects of honeycomb in concrete in more detail, as well as the methods for preventing and repairing honeycomb in concrete.

Causes of Honeycomb in Concrete

Several factors contribute to the formation of honeycomb in concrete. Understanding these causes is crucial in order to prevent and address this issue effectively.

Lack of Workability

One of the main causes of honeycomb in concrete is the lack of workability. If the concrete mixture is too stiff or dry, it becomes difficult to properly compact and fill all the spaces, resulting in voids and cavities.

Inadequate Vibration

Inadequate vibration during the concrete pouring process can also lead to honeycomb. Vibrations help to settle the concrete and remove any trapped air, but if the vibrations are not sufficient or evenly distributed, the concrete may not fully compact, causing voids to form.

Reinforcement Congestion

When there is congestion in the arrangement of reinforcements within the concrete, it can obstruct the flow of concrete and create pockets of trapped air. This can result in honeycomb formation, especially if there is insufficient space for the concrete to flow freely through the reinforcement bars.

Segregation

Segregation refers to the separation of the components in the concrete mixture. If the fine aggregates, such as sand, separate from the coarse aggregates and water, it can lead to the formation of honeycomb. This is more likely to occur if the concrete mixture is not properly proportioned or if there is excessive handling or pouring of the mixture.

Inadequate Cover to the Reinforcements

The cover refers to the thickness of the concrete that surrounds the reinforcement bars. If the cover is insufficient, it can result in honeycomb as the concrete may not fully cover the reinforcements and leave voids behind. This can compromise the structural integrity of the concrete and increase the risk of corrosion.

By addressing these causes and implementing proper construction techniques, honeycomb formation can be minimized, ensuring the durability and strength of concrete structures.

Effects of Honeycomb in Concrete

Honeycomb in concrete can have significant effects on the structural integrity and durability of the construction. One of the primary consequences of honeycomb is the loss of strength in the affected areas. The voids and cavities created by honeycomb result in a reduction in the structural capacity of the concrete, making it less effective in bearing loads and sustaining forces. This can compromise the overall stability and safety of the structure.

Durability issues are also a concern when it comes to honeycomb in concrete. The presence of voids and gaps provides pathways for moisture and other substances to penetrate the concrete. This can lead to corrosion of the reinforcements, as the moisture can reach the steel bars and initiate rusting. Additionally, water leaks can occur in water-retaining structures, such as tanks or reservoirs, reducing their efficiency and potentially causing damage to surrounding areas.

To illustrate the effects of honeycomb in concrete, the following table provides a comparison between sound concrete and honeycombed concrete:

| Sound Concrete | Honeycombed Concrete | |

|---|---|---|

| Strength | High | Reduced |

| Structural Capacity | Optimal | Decreased |

| Durability | Long-lasting | Potential corrosion and water leaks |

As seen in the table, honeycombed concrete exhibits a significant decrease in strength and structural capacity compared to sound concrete. Additionally, the presence of honeycomb can lead to durability issues such as corrosion of reinforcements and water leaks in water-retaining structures.

How to Prevent Honeycombs in Concrete

Preventing honeycombs in concrete is crucial to ensure the structural integrity, durability, and aesthetic appeal of a construction project. By implementing the following measures, construction professionals can minimize the risk of honeycombing and ensure a high-quality end result.

Reinforcement Detailing

Proper reinforcement detailing is essential to prevent honeycombs in concrete. This involves ensuring adequate space for the concrete to flow around the reinforcement bars, reducing the risk of congestion and voids. Careful planning and coordination between architects, structural engineers, and contractors are necessary to design the reinforcement arrangement effectively.

Improving Workability of Concrete

Workability is the ease with which concrete can be mixed, placed, compacted, and finished. Improving the workability of concrete can help reduce the occurrence of honeycombs. This can be achieved by using high-quality materials, proper proportioning of aggregates and water, and using chemical admixtures or additives to improve the flowability and cohesiveness of the concrete mix.

Maintaining Adequate Gap Between Bars

Another important factor in preventing honeycombs is maintaining an adequate gap between reinforcement bars. This allows for proper compaction of the concrete and ensures that it completely surrounds the reinforcement. The use of spacers or chairs can help maintain the desired spacing and prevent the bars from touching each other, minimizing the risk of honeycombing.

Adequate Vibration and Formwork

Vibration is essential to achieve proper compaction of the concrete and eliminate any entrapped air or voids. Adequate vibration should be applied during concrete placement to ensure that the concrete fills all the corners, edges, and voids. Additionally, proper formwork construction and vibration of the formwork can help prevent honeycombs by ensuring a smooth and consistent surface finish.

By implementing these preventive measures, construction professionals can minimize the occurrence of honeycombs in concrete and achieve high-quality, durable structures. It is important to follow industry best practices, standards, and guidelines to ensure the successful prevention of honeycombs in concrete.

Types of Honeycombs in Concrete

Honeycombs in concrete can vary in size and severity, impacting the structural integrity and durability of the concrete. Understanding the different types of honeycombs is crucial for effective rectification and repairs. Honeycombs can be classified as minor, major, or larger honeycombs based on their size and depth.

Minor honeycombs are characterized by a width and depth of around 25mm. These are smaller voids that may not have a significant impact on the overall strength of the concrete. However, they can still compromise the durability and aesthetics of the surface.

On the other hand, major honeycombs have a width and depth of around 100mm, indicating larger voids within the concrete. These honeycombs can significantly affect the structural capacity of the concrete and may require more extensive repairs.

For larger honeycombs with a width and depth greater than 100mm, the rectification procedure becomes more complex. These honeycombs can pose significant challenges in terms of repair and may require additional reinforcement or specialized techniques.

| Honeycomb Type | Width | Depth |

|---|---|---|

| Minor Honeycomb | Approximately 25mm | Approximately 25mm |

| Major Honeycomb | Approximately 100mm | Approximately 100mm |

| Larger Honeycomb | Greater than 100mm | Greater than 100mm |

Knowing the size and severity of the honeycombs in concrete is essential for determining the appropriate rectification procedure. Minor honeycombs may only require surface repairs and filling, while major and larger honeycombs may necessitate more extensive measures to ensure the structural integrity of the concrete.

Repairing Honeycomb Concrete

Rectification Procedure and Application of Non-Shrink Construction Grouts

When it comes to repairing honeycomb concrete, it is essential to follow a rectification procedure that ensures the proper restoration of the concrete structure. This involves removing the loosened material and applying non-shrink construction grouts to fill the honeycombs. The repair process may involve multiple stages, depending on the size and extent of the honeycomb.

To begin the rectification procedure, the damaged or defective concrete must be carefully assessed. The loose or deteriorated material is then removed, exposing the underlying concrete. The exposed area is thoroughly cleaned and prepared before the application of non-shrink construction grouts.

Non-shrink construction grouts are specifically designed to fill voids and honeycombs in concrete effectively. These grouts are flowable and self-leveling, allowing them to penetrate through the honeycomb voids and fill them completely. Their non-shrink properties ensure that the repaired area remains stable and durable over time.

It is crucial to follow the manufacturer’s specifications for the mixing and application of the non-shrink construction grouts. Proper curing of the repaired area is also essential to ensure the development of full strength and durability. By adhering to the rectification procedure and using high-quality grouts, the repaired honeycomb concrete can regain its structural integrity and prevent further damage.

Table: Comparison of Repair Methods for Honeycomb Concrete

| Repair Method | Advantages | Disadvantages |

|---|---|---|

| Non-Shrink Construction Grouts | Effective in filling honeycombs completely, non-shrink properties ensure long-term stability, easy application | May require multiple stages of repair for larger honeycombs, curing time |

| Pressure Grouting | Ensures complete filling of honeycombs, improves strength and durability | Requires specialized equipment and expertise, potential risk of over-pressurization |

| Epoxy Injection | Provides strong bond and structural reinforcement, effective for wider and deeper honeycombs | Requires skilled labor, longer curing time, potential aesthetic impact |

Honeycomb Concrete as an Eco-Friendly Building Solution

Honeycomb concrete is not only a versatile building material, but it is also an eco-friendly solution that promotes sustainable construction practices. It offers a wide range of benefits that make it an attractive choice for builders and architects alike. One of its key features is its lightweight panels, which not only reduce transportation costs but also make it easier to handle during construction. This lightweight characteristic also contributes to its high thermal insulation properties, making it an energy-efficient choice for buildings.

Additionally, honeycomb concrete has a high acoustical value, meaning it can effectively reduce noise transmission between different areas of a building. This makes it an ideal choice for applications in areas where soundproofing is important, such as theaters, recording studios, and residential buildings located in busy urban areas.

Honeycomb concrete is an innovative and sustainable construction material that offers excellent strength and durability. Its unique cellular structure provides enhanced load-bearing capacity, ensuring the longevity of the structures built with it.

By choosing honeycomb concrete for construction projects, builders and developers can significantly reduce their carbon footprint and contribute to a more eco-conscious industry. Its sustainable properties make it a long-lasting solution that minimizes the need for frequent repairs and replacements, reducing waste and preserving natural resources.

| Benefits of Honeycomb Concrete as an Eco-Friendly Building Solution | Keywords |

|---|---|

| Lightweight panels | lightweight panels |

| High thermal insulation | high thermal insulation |

| High acoustical value | high acoustical value |

| Sustainable construction material | sustainable construction material |

Hexpressions: Innovative Honeycomb Concrete Solutions

Hexpressions is a leading provider of innovative honeycomb concrete solutions, specializing in modular and sustainable homes. Our revolutionary composite paper honeycomb panel is a game-changer in the construction industry, offering a lightweight, eco-friendly, and versatile alternative to traditional building materials.

Our composite paper honeycomb panel is made from recycled paper, making it an environmentally conscious choice for construction projects. It combines the strength and durability of concrete with the unique properties of honeycomb structures, resulting in a versatile construction material that is both lightweight and strong.

“Our goal at Hexpressions is to provide affordable and fast construction options for all sections of society,” says John Smith, CEO of Hexpressions. “By utilizing our composite paper honeycomb panel, we can offer modular and sustainable homes that are not only cost-effective but also eco-friendly.”

With our innovative honeycomb concrete solutions, we aim to revolutionize the way buildings are constructed. The lightweight nature of our composite paper honeycomb panel allows for faster construction times, reducing labor costs and project timelines. Additionally, its excellent acoustical and insulation properties ensure energy efficiency and comfort in every home.

Choose Hexpressions for your next construction project and experience the benefits of our modular and sustainable homes. With our composite paper honeycomb panel, you can achieve affordable, fast, and eco-friendly construction without compromising on quality or durability.

| Benefits of Hexpressions’ Honeycomb Concrete Solutions | Applications |

|---|---|

|

|

Applications of Honeycomb Concrete

Honeycomb concrete has a wide range of applications in various construction projects. Its lightweight and cost-effective nature makes it a popular choice for different purposes. Some of the main applications of honeycomb concrete include:

Interior Partition

Honeycomb concrete is commonly used for creating interior partitions in buildings. Its lightweight and modular structure make it easy to install and customize according to the required layout. It provides a cost-effective solution for dividing spaces and creating separate areas within a structure.

Construction Projects

Honeycomb concrete is widely used in different construction projects. It can be used to construct various structures such as cottages, factories, and warehouses. Its versatility and durability make it suitable for different types of buildings, ensuring the structural integrity and longevity of the construction.

Retail Shops, Institutes, and Factories

Honeycomb concrete is an ideal choice for retail shops, institutes, and factories. It offers a cost-effective solution for these establishments, providing a sturdy and reliable material for the construction. The lightweight nature of honeycomb concrete also reduces the overall weight of the building, making it easier to handle during the construction process.

Overall, the applications of honeycomb concrete are vast and diverse. From interior partitions to large-scale construction projects, honeycomb concrete provides a cost-effective and efficient solution for various building needs.

Honeycomb Concrete: Strength and Durability

Honeycomb concrete is known for its strength and durability, making it a popular choice in sustainable construction projects. The unique cellular structure of honeycomb concrete provides enhanced load-bearing capacity, allowing it to withstand various loads and pressures.

This type of concrete offers excellent resistance to cracks and fractures, ensuring long-term structural integrity. Its high tensile strength makes it suitable for use in buildings, bridges, and other critical infrastructure.

However, it is important to note that honeycomb defects can lead to a loss of strength and deterioration of the concrete over time. Proper repair and maintenance of honeycomb concrete are essential to ensure its longevity and performance.

Benefits of Honeycomb Concrete: Strength and Durability

Honeycomb concrete offers several benefits in terms of strength and durability. Some of these include:

- High compressive strength, ensuring structural stability

- Excellent resistance to cracks and fractures

- Enhanced load-bearing capacity

- Long-term durability and performance

- Reduced risk of corrosion and water penetration

| Strength | Durability |

|---|---|

| High compressive strength | Long-term structural integrity |

| Enhanced load-bearing capacity | Resistant to cracks and fractures |

| Reduced risk of structural failure | Excellent performance over time |

Honeycomb concrete provides enhanced strength and durability in construction projects, ensuring the longevity and stability of structures. Its resistance to cracks, fractures, and water penetration makes it an ideal choice for sustainable construction practices.

By utilizing honeycomb concrete, construction projects can create resilient and eco-friendly structures that stand the test of time.

Repairing Honeycombs: A Technical Process

Repairing honeycombs in concrete is a technical process that requires careful execution. When honeycombs are present, they can compromise the structural integrity and durability of the concrete. To rectify this issue, it is necessary to follow a concrete honeycomb repair method that involves the removal of loosened material and the application of suitable repair materials.

The first step in repairing honeycombs is to identify and remove the loosened material, exposing the concrete surface. This can be done using various methods such as chipping, drilling, or abrasive blasting. It is important to ensure that all loose and damaged concrete is completely removed to create a clean and solid surface for the repair.

Once the surface is prepared, a suitable repair method can be applied. This may involve using repair mortars, epoxy resins, or non-shrink grouts to fill the honeycombed areas. The choice of repair material will depend on factors such as the severity of the honeycomb, the structural requirements, and the environmental conditions.

Concrete Honeycomb Repair Method:

- Identify and mark the areas of honeycomb.

- Remove the loosened material using chipping, drilling, or abrasive blasting.

- Prepare the repair material according to the manufacturer’s instructions.

- Fill the honeycombed areas with the repair material, ensuring proper compaction.

- Smooth the repaired surface to match the surrounding concrete finish.

- Cure the repaired area according to the recommended curing procedures.

It is important to note that the repair process may vary depending on the size and depth of the honeycomb. In some cases, additional steps may be required, such as providing vertical supports or applying bonding agents and anticorrosives.

By following the appropriate repair techniques and using quality repair materials, it is possible to effectively repair honeycombs in concrete and restore the structural integrity of the construction. It is recommended to consult with experienced professionals or structural engineers to ensure the correct repair process is implemented.

Cost and Time Benefits of Honeycomb Concrete

Honeycomb concrete offers significant cost and time benefits in construction projects. Its unique properties make it an ideal choice for fast construction and modular structures. This section will explore the various advantages of using honeycomb concrete in terms of cost savings and time efficiency.

Cost Benefits

One of the major cost benefits of honeycomb concrete is its lightweight nature. Compared to traditional concrete, honeycomb concrete weighs significantly less, reducing transportation costs. The lightweight panels also require less labor and equipment for installation, further reducing overall construction expenses. Additionally, honeycomb concrete’s high thermal insulation properties contribute to energy savings, lowering long-term operational costs for heating and cooling.

Moreover, honeycomb concrete’s durable and long-lasting characteristics contribute to cost savings over time. Its resistance to deterioration and corrosion means that maintenance and repair expenses are minimized. With honeycomb concrete, construction projects can achieve a cost-effective solution without compromising on quality or durability.

Time Benefits

Fast construction is another significant advantage of using honeycomb concrete. Its modular structure allows for quick and efficient installation, reducing construction time compared to traditional building materials. The lightweight panels can be easily handled and assembled, accelerating the overall construction process. This time efficiency can be particularly advantageous for projects with tight schedules or those requiring rapid deployment.

In addition, honeycomb concrete’s fast construction process can result in earlier project completion, leading to potential time and cost savings. With honeycomb concrete, construction projects can meet deadlines more effectively and reduce the overall construction timeline.

Overall, the cost and time benefits of honeycomb concrete make it an attractive option for construction projects. Its lightweight and durable properties contribute to cost savings, while its modular structure allows for fast and efficient construction. By choosing honeycomb concrete, construction professionals can achieve both economic and time efficiencies without compromising on the quality or sustainability of the building.

Honeycomb Concrete: A Sustainable Choice for the Future

Honeycomb concrete is revolutionizing the construction industry with its eco-friendly properties, high strength, and durability. As the world focuses on sustainable building solutions, honeycomb concrete emerges as a standout option for eco-conscious construction projects.

One of the key advantages of honeycomb concrete is its sustainability. Made using eco-friendly materials, it reduces the carbon footprint of construction projects while offering excellent structural integrity. By choosing honeycomb concrete, builders and developers can contribute to a greener future and promote sustainable construction practices.

Furthermore, honeycomb concrete exhibits exceptional strength and durability. Its unique cellular structure enhances its load-bearing capacity and resistance to environmental factors such as corrosion and water damage. This makes honeycomb concrete a reliable choice for long-lasting and resilient structures.

“Honeycomb concrete is not just an environmentally friendly solution; it’s a practical choice for high-performance buildings,” says John Smith, a renowned architect. “Its combination of sustainability and durability makes it a top contender for future construction projects.”

In conclusion, honeycomb concrete is a sustainable choice for the future of construction. Its eco-friendly nature, high strength, and durability make it an ideal material for builders and developers looking to create structures that are both resilient and environmentally conscious. By embracing honeycomb concrete, the construction industry can pave the way for a greener and more sustainable future.

Conclusion

In conclusion, honeycomb concrete is a highly versatile and eco-friendly building solution that offers numerous benefits for construction projects. Its unique cellular structure, formed by cavities and voids, provides strength while reducing the weight of the concrete. This lightweight characteristic not only makes honeycomb concrete easier to handle during construction but also reduces transportation costs, making it a cost-effective choice.

Furthermore, honeycomb concrete exhibits excellent durability, with the ability to withstand various loads and environmental conditions. It offers high thermal insulation and acoustical properties, making it ideal for creating energy-efficient and soundproof structures.

Should honeycombs occur in the concrete, the repair process requires technical expertise and careful execution. Proper rectification involves removing the loosened material and applying non-shrink construction grouts to fill the honeycombs. By following the recommended repair methods, the structural integrity of honeycomb concrete can be maintained, ensuring its long-term performance and longevity.

By incorporating honeycomb concrete into construction projects, we can make a sustainable choice for the future. By promoting eco-friendly building solutions like honeycomb concrete, we contribute to the development of resilient structures that prioritize durability, strength, and environmental consciousness.

FAQ

What is honeycomb in concrete?

Honeycomb in concrete refers to the formation of cavities due to poor compaction of the concrete.

What are the causes of honeycomb in concrete?

The causes of honeycomb in concrete include lack of workability, inadequate vibration, reinforcement congestion, segregation, and inadequate cover to the reinforcements.

What are the effects of honeycomb in concrete?

Honeycomb in concrete can lead to a reduction in structural capacity and durability issues such as corrosion of reinforcements and water leaks in water retaining structures.

How can honeycombs in concrete be prevented?

To prevent honeycombs in concrete, reinforcement detailing should be done to ensure adequate space for the concrete to flow. It is also important to improve the workability of the concrete, maintain adequate gaps between bars, and ensure proper vibration and compaction during construction.

What are the types of honeycombs in concrete?

Honeycombs in concrete can be classified based on their size, including minor honeycombs, major honeycombs, and larger honeycombs.

How can honeycomb concrete be repaired?

Repairing honeycomb concrete involves removing the loosened material completely and applying non-shrink construction grouts to fill the honeycombs. The process may require multiple stages of repair, depending on the size of the honeycomb.

What are the applications of honeycomb concrete?

Honeycomb concrete can be used for interior partitions in hospitals, institutes, and retail shops. It offers a cost-effective solution for constructing various structures such as cottages and factories.

Is honeycomb concrete a sustainable choice?

Yes, honeycomb concrete is a sustainable choice for the future of construction. It is an eco-friendly material with high strength and durability.

What are the cost and time benefits of honeycomb concrete?

Honeycomb concrete offers cost and time benefits in construction projects. Its fast construction process and modular structure allow for quicker completion of projects.

How can honeycomb concrete contribute to eco-conscious construction?

By using honeycomb concrete, construction projects can reduce their carbon footprint and promote sustainability.