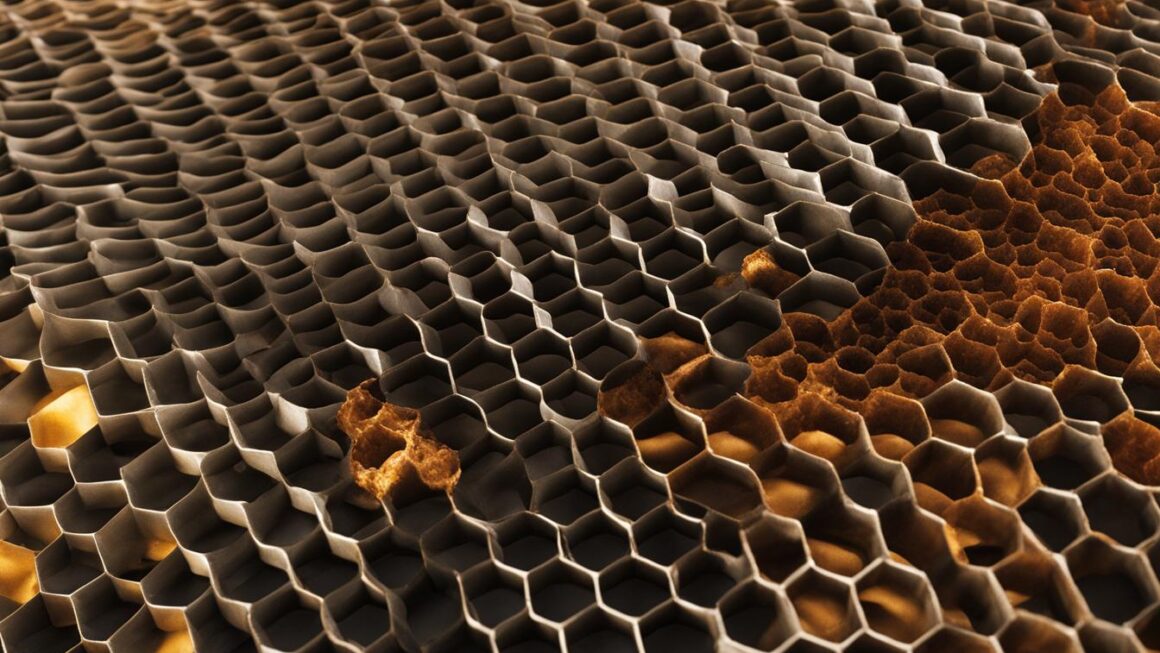

Honeycomb core panels are innovative and durable solutions that offer lightweight yet strong construction materials for a wide range of applications. These panels utilize a honeycomb structure, creating a high strength-to-weight ratio that allows for significant weight reduction without compromising structural integrity. They are commonly used in aerospace and marine applications due to their exceptional impact resistance and thermal insulation properties. With their versatility and strength, honeycomb core panels are ideal for various construction projects.

Key Takeaways:

- Honeycomb core panels are lightweight and durable solutions for construction projects.

- They utilize a honeycomb structure, providing a high strength-to-weight ratio.

- These panels are commonly used in aerospace and marine applications.

- They offer excellent impact resistance and thermal insulation properties.

- Honeycomb core panels are versatile and suitable for various construction projects.

The Benefits of Honeycomb Core Panels

Honeycomb core panels offer a multitude of benefits for construction projects. One of the key advantages is their lightweight nature, which reduces the overall weight of structures. This makes them easier to handle and transport, resulting in increased efficiency during construction. Despite their lightweight design, honeycomb core panels provide excellent impact resistance, ensuring durability and longevity. This makes them a reliable choice for applications where structural integrity is crucial.

Another significant benefit of honeycomb core panels is their thermal insulation properties. The honeycomb structure creates a natural insulation barrier, which helps to regulate temperature and reduce heat transfer. This makes honeycomb core panels particularly valuable in applications where energy efficiency is a priority, such as in environmentally conscious building projects.

Peter Johnson, a construction engineer, emphasizes the advantages of honeycomb core panels, stating, “Their lightweight nature and impressive impact resistance make honeycomb core panels an excellent choice for a wide range of construction projects. They offer structural integrity while reducing overall weight, making them highly versatile and cost-effective.”

Honeycomb core panels are a popular choice for various construction applications due to their numerous benefits. Whether it’s their lightweight composition, exceptional impact resistance, or thermal insulation properties, these panels continue to provide durable and efficient solutions for modern construction projects.

| Benefits of Honeycomb Core Panels |

|---|

| Lightweight |

| Excellent impact resistance |

| Thermal insulation properties |

Honeycomb Core Panels in Aerospace Applications

Honeycomb core panels are widely utilized in the aerospace industry for their exceptional lightweight and high-strength properties. These panels provide a durable and lightweight solution for various applications in aircraft construction. With their honeycomb structure, they offer an impressive strength-to-weight ratio, allowing for significant weight reduction without compromising structural integrity.

Honeycomb core panels exhibit excellent impact resistance, making them suitable for withstanding the demanding conditions of aerospace environments. They are commonly used for interior fittings, flooring, and structural components in different aircraft models. The lightweight nature of these panels contributes to fuel efficiency, allowing for increased range and payload capacity.

Moreover, honeycomb core panels offer thermal insulation properties, helping to regulate temperature within the aircraft. This is particularly important for maintaining comfort and safety for passengers and crew members. The ability to provide both lightweight construction and thermal insulation makes honeycomb core panels an ideal choice for aerospace applications.

Advantages of Honeycomb Core Panels in Aerospace:

- Significant weight reduction without compromising structural integrity

- Exceptional impact resistance for withstanding harsh conditions

- Thermal insulation properties for temperature regulation

- Increased fuel efficiency for improved range and payload capacity

Table: Applications of Honeycomb Core Panels in Aerospace

| Application | Description |

|---|---|

| Interior Fittings | Used for cabin interiors, providing lightweight and durable solutions for seating, storage, and fixtures. |

| Flooring | Provides lightweight and strong flooring solutions for enhanced safety and comfort. |

| Structural Components | Utilized in the construction of wings, fuselage, and other structural elements for their strength and weight-saving properties. |

Honeycomb Core Panels in Marine Applications

Honeycomb core panels are widely used in marine applications due to their lightweight and durable nature. These panels provide a strong and lightweight alternative to traditional construction materials, making them ideal for boat building and ship construction. With their exceptional impact resistance, honeycomb core panels can withstand the forces of the sea and ensure the longevity of marine structures.

In boat building, honeycomb core panels are commonly used for interior fittings, hull construction, and structural components. Their lightweight nature allows for easier handling and transportation during the construction process, while still providing the necessary strength and durability. The honeycomb structure of these panels also contributes to their thermal insulation properties, offering energy efficiency benefits in marine environments.

Table:

| Application | Benefits |

|---|---|

| Interior fittings | – Lightweight |

| Hull construction | – Excellent impact resistance |

| Structural components | – Durable and long-lasting |

With their versatility and strength, honeycomb core panels have become a preferred choice for marine applications. They offer numerous advantages, including weight reduction, impact resistance, and thermal insulation. Whether it’s for small boats or large ships, honeycomb core panels provide a reliable and efficient construction solution for the marine industry.

Honeycomb Core Panels in Construction

Honeycomb core panels are highly versatile and durable construction materials that offer numerous benefits for a wide range of applications. These lightweight panels are well-suited for use in construction projects where structural integrity, impact resistance, and thermal insulation are essential. With their unique honeycomb structure, honeycomb core panels provide exceptional strength-to-weight ratio, making them an ideal choice for structural panels in buildings.

One of the key advantages of honeycomb core panels in construction is their excellent impact resistance. These panels can withstand significant forces, ensuring durability and safety in buildings. Whether it’s protecting against potential impacts or withstanding extreme weather conditions, honeycomb core panels offer reliable performance.

In addition to their impact resistance, honeycomb core panels also offer thermal insulation properties. The honeycomb structure creates a natural insulation barrier, which helps regulate heat flow and contributes to energy efficiency in buildings. This insulation capability can lead to energy savings and improved comfort.

Applications in Construction

In construction, honeycomb core panels have a wide range of applications. They are commonly used for wall cladding, providing a lightweight yet strong solution that enhances the aesthetics of buildings. These panels are also used for roofing, offering durability and protection against the elements. Additionally, honeycomb core panels are used for partitions and other structural elements, providing stability and strength.

With their lightweight nature, impact resistance, and thermal insulation properties, honeycomb core panels offer an excellent solution for various construction projects. Whether it’s a commercial building, residential complex, or infrastructure project, these panels provide the reliability and performance needed to meet the demands of modern construction.

| Advantages | Benefits |

|---|---|

| Lightweight | Reduces overall weight of structures, making them easier to handle and transport |

| Impact resistance | Ensures durability and longevity, even in challenging environments |

| Thermal insulation | Contributes to energy efficiency in buildings, leading to potential energy savings |

| Versatility | Can be used for various applications such as wall cladding, roofing, partitions, and structural elements |

In summary, honeycomb core panels are an excellent choice for construction projects due to their lightweight, impact resistance, and thermal insulation properties. These panels provide the strength and durability needed for structural panels in buildings, while offering numerous advantages over conventional construction materials. From wall cladding to roofing, honeycomb core panels offer versatility and performance that make them a valuable asset in modern construction.

Other Applications of Honeycomb Core Panels

Honeycomb core panels have proven to be incredibly versatile, finding applications beyond aerospace, marine, and construction industries. These lightweight panels offer a range of benefits that make them suitable for various uses. Let’s explore some of the other applications where honeycomb core panels excel.

Honeycomb Core Panels in the Automotive Industry

In the automotive industry, honeycomb core panels are used to create lightweight components and body panels. The lightweight nature of these panels helps reduce the overall weight of vehicles, resulting in improved fuel efficiency and performance. Additionally, the impact resistance of honeycomb core panels ensures enhanced safety in case of collisions.

Honeycomb Core Panels in Furniture Manufacturing

Honeycomb core panels are also utilized in the production of furniture. These panels provide lightweight yet sturdy materials that can be used for various designs. The versatility of honeycomb core panels allows for the creation of furniture pieces that are not only aesthetically pleasing but also durable and long-lasting.

| Application | Advantages |

|---|---|

| Automotive | – Lightweight construction – Improved fuel efficiency – Enhanced impact resistance |

| Furniture | – Lightweight and sturdy materials – Design versatility – Long-lasting durability |

“Honeycomb core panels offer lightweight yet strong construction materials that can be customized to suit specific project requirements.”

Honeycomb Core Panels in Packaging and Transportation

The exceptional impact resistance of honeycomb core panels makes them ideal for protective packaging and transportation containers. These panels provide a reliable and robust solution to ensure the safe transportation of goods. Whether it’s fragile items or heavy machinery, honeycomb core panels offer the necessary strength to withstand the rigors of transportation.

With their lightweight construction, impact resistance, and numerous customization options, honeycomb core panels continue to prove their worth in a wide range of applications. From automotive components to furniture manufacturing and packaging, these panels offer durability, strength, and versatility.

Case Studies: Honeycomb Core Panels in Real-Life Projects

Honeycomb core panels have been successfully implemented in various real-life projects across different industries. These case studies highlight the versatility and effectiveness of honeycomb core panels in aerospace, marine, and construction applications.

Aerospace Applications

In the aerospace industry, honeycomb core panels have proven to be a reliable and efficient choice for a range of applications. One notable case study is the use of honeycomb core panels in the interior fittings of aircraft. These panels provide lightweight yet strong solutions for cabin partitions, overhead bins, and galleys. Their exceptional impact resistance ensures durability and passenger safety.

“The implementation of honeycomb core panels in our aircraft interiors has improved overall efficiency and passenger comfort. The lightweight nature of the panels reduces fuel consumption while maintaining structural integrity.” – Chief Engineer, Aerospace Company

Marine Applications

Honeycomb core panels are also widely utilized in the marine industry, offering lightweight and durable solutions for various applications. One case study showcases their use in boat building, specifically in the construction of hulls. By using honeycomb core panels, boat builders can achieve a strong and lightweight structure, resulting in improved fuel efficiency and better performance.

Construction Projects

Honeycomb core panels have made an impact in the construction industry as well. In a case study involving the construction of a high-rise residential tower, honeycomb core panels were used for wall cladding. These panels not only provided an aesthetically pleasing exterior but also contributed to the overall energy efficiency of the building. The honeycomb structure acted as a natural thermal insulator, reducing heat transfer and improving the building’s energy performance.

| Project | Industry | Application |

|---|---|---|

| Kings Domain Residential Tower | Construction | Exterior Wall Cladding |

| Boat Building | Marine | Hull Construction |

| Aircraft Interior Fittings | Aerospace | Cabin Partitions, Overhead Bins, Galleys |

These case studies demonstrate the wide-ranging applications of honeycomb core panels and highlight their effectiveness in providing lightweight, durable, and energy-efficient solutions for real-life projects.

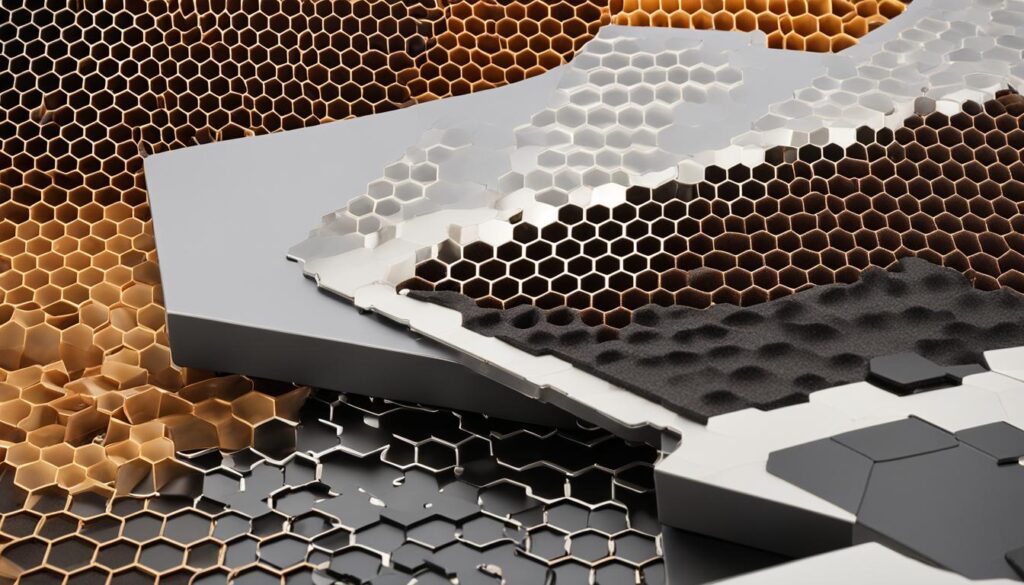

Quality Control in Honeycomb Core Panel Production

To ensure the highest quality of honeycomb core panels, manufacturers implement strict quality control measures. These measures include adhering to ISO 9001 standards, which ensure consistent and standardized production practices. The use of ISO 9001 standards demonstrates the manufacturer’s commitment to producing reliable and durable honeycomb core panels that meet industry standards.

Experienced quality control staff are assigned to projects to monitor the production process and address any potential defects or issues. They conduct regular inspections, ensuring that each step of the manufacturing process meets the required specifications. In-house laboratory testing is also conducted to assess bonding performance and identify any defects or weaknesses in the panels.

The data from these tests is carefully analyzed, and any necessary adjustments are made to improve the quality of the honeycomb core panels. By conducting rigorous quality control procedures, manufacturers can confidently produce honeycomb core panels that are of the highest quality and provide reliable solutions for various applications.

| Quality Control Measures | Benefits |

|---|---|

| Adherence to ISO 9001 standards | Ensures consistent and standardized production practices |

| Experienced quality control staff | Monitors the production process and addresses defects or issues |

| In-house laboratory testing | Assesses bonding performance and identifies defects or weaknesses |

| Data analysis and adjustments | Improves the quality of honeycomb core panels |

Customization Options for Honeycomb Core Panels

Honeycomb core panels offer a wide range of customization options to meet the specific requirements of different projects. These options include size, coating, and surface options, allowing for flexibility in design and installation.

Size Options

One of the key advantages of honeycomb core panels is their ability to be produced in various sizes. This flexibility allows for customization to fit specific project needs. Whether it’s a small interior application or a large-scale construction project, honeycomb core panels can be tailored to the desired dimensions, ensuring a perfect fit.

Coating Options

Honeycomb core panels can be coated with different materials to provide added protection and aesthetics. Some common coating options include PVDF, PE, and powdered coated finishes. These coatings not only enhance the visual appeal of the panels but also provide weather resistance properties, ensuring long-term durability in different environments.

Surface Options

When it comes to surface options, honeycomb core panels offer a wide variety of choices. From stone and porcelain to ceramic and natural finishes, there are numerous surface options available to suit different design preferences. These surface options not only add visual appeal but also contribute to the overall versatility and customization of honeycomb core panels.

With these customization options, honeycomb core panels can be tailored to meet the specific needs of different applications. Whether it’s size, coating, or surface options, these panels offer the flexibility and versatility required for a wide range of projects.

The Future of Honeycomb Core Panels

Honeycomb core panels are poised to revolutionize the construction industry with their lightweight properties, exceptional strength, and sustainability. As the demand for lightweight construction materials continues to grow, honeycomb core panels are expected to play a crucial role in meeting this need and driving future trends in the industry.

One of the key future trends for honeycomb core panels is the continuous improvement in lightweight construction. The unique honeycomb structure provides a high strength-to-weight ratio, allowing for significant weight reduction without compromising structural integrity. This lightweight nature not only makes them easier to handle and transport but also contributes to energy efficiency in buildings. With ongoing advancements in material science and manufacturing technologies, honeycomb core panels are expected to become even lighter, making them an ideal choice for a wide range of applications.

Honeycomb core panels have the potential to transform the way we build by offering sustainable materials for construction projects. With a focus on reducing carbon footprint and promoting eco-friendly practices, the construction industry is increasingly turning towards sustainable building materials. Honeycomb core panels, with their lightweight and durable properties, align with these sustainability goals. Made from recyclable materials, these panels offer a greener alternative to traditional construction materials while still maintaining their exceptional strength and impact resistance.

In addition to lightweight construction and sustainability, another future trend for honeycomb core panels is their expanding range of applications. While these panels are already widely used in industries such as aerospace, marine, automotive, and construction, their versatility opens up opportunities for new uses. From protective packaging to furniture manufacturing, honeycomb core panels offer a lightweight and sturdy solution for various design needs. As the demand for innovative and efficient materials grows, honeycomb core panels are likely to find their way into even more industries and applications in the future.

| Advantages of Honeycomb Core Panels for the Future |

|---|

| Lightweight construction |

| Sustainable materials |

| Expanded range of applications |

Summary

The future of honeycomb core panels is bright, with continued advancements and innovations on the horizon. These panels offer lightweight construction solutions, making them ideal for various industries and applications. The increasing focus on sustainability in the construction industry further positions honeycomb core panels as a promising choice for eco-friendly building practices. As the demand for lightweight and sustainable materials continues to rise, honeycomb core panels are expected to play a significant role in shaping the future of construction.

Advantages of Honeycomb Core Panels Over Conventional Materials

Honeycomb core panels offer several advantages over conventional construction materials, making them a preferred choice for modern construction projects.

Firstly, one of the key advantages of honeycomb core panels is their lightweight construction. These panels are significantly lighter than traditional materials, which simplifies transportation and installation processes. The reduced weight not only improves efficiency but also minimizes the load on supporting structures, allowing for more flexibility in design and construction.

Secondly, honeycomb core panels provide exceptional impact resistance. The unique honeycomb structure absorbs and disperses impact energy, making them highly durable and resistant to damage. This feature ensures the longevity of structures, even in challenging environments or high-traffic areas, where durability is paramount.

Additionally, honeycomb core panels offer excellent thermal insulation properties. The air pockets trapped within the honeycomb structure act as natural insulators, reducing heat transfer between the interior and exterior of a building. This results in improved energy efficiency and reduced heating or cooling costs. The thermal insulation provided by honeycomb core panels contributes to creating a comfortable and sustainable environment.

Table: Comparison of Honeycomb Core Panels and Conventional Materials

| Advantages | Honeycomb Core Panels | Conventional Materials |

|---|---|---|

| Weight | Lightweight construction reduces overall weight of structures, simplifying transportation and installation. | Heavier materials can increase costs and require more complex installation procedures. |

| Impact Resistance | Honeycomb structure absorbs and disperses impact energy, providing exceptional durability and resistance to damage. | Traditional materials may be more prone to damage from impacts, requiring frequent repairs or replacements. |

| Thermal Insulation | Air pockets in the honeycomb structure act as natural insulators, reducing heat transfer and improving energy efficiency. | Less effective insulation may result in increased energy consumption and higher heating or cooling costs. |

Table: Comparison of Honeycomb Core Panels and Conventional Materials

Conclusion

Honeycomb core panels offer significant advantages over conventional materials in terms of lightweight construction, impact resistance, and thermal insulation. These panels provide a durable and efficient solution for modern construction projects, contributing to sustainable and energy-efficient building practices. As the demand for lightweight and versatile materials continues to grow, honeycomb core panels are expected to play a crucial role in the future of construction.

Conclusion

In summary, honeycomb core panels offer lightweight and durable construction materials that are highly versatile and suitable for a wide range of applications. With their unique honeycomb structure, these panels provide an excellent strength-to-weight ratio, allowing for significant weight reduction without compromising structural integrity. The exceptional impact resistance of honeycomb core panels ensures durability and longevity, making them ideal for challenging environments.

Furthermore, honeycomb core panels offer natural thermal insulation properties, contributing to energy efficiency in buildings. This makes them a popular choice for applications where sustainability and cost-effectiveness are priorities. With ongoing advancements in material science and manufacturing technologies, the future of honeycomb core panels looks promising. These panels are expected to become even lighter, stronger, and more durable, and will continue to play a significant role in the development of lightweight, sustainable, and efficient construction solutions.

As the demand for lightweight panels and construction materials continues to grow, honeycomb core panels are poised to meet the industry’s evolving needs. Whether in aerospace, marine, automotive, or construction applications, honeycomb core panels provide a reliable and versatile solution. With their exceptional impact resistance, thermal insulation properties, and future trends in lightweight construction, honeycomb core panels are set to shape the future of the construction industry.

FAQ

What are honeycomb core panels?

Honeycomb core panels are lightweight and durable construction materials that utilize a honeycomb structure, providing a high strength-to-weight ratio.

What are the benefits of honeycomb core panels?

Honeycomb core panels offer advantages such as lightweight construction, excellent impact resistance, and thermal insulation properties.

Where are honeycomb core panels commonly used?

Honeycomb core panels find applications in aerospace, marine, automotive, and construction industries.

In which aerospace applications are honeycomb core panels utilized?

Honeycomb core panels are used in aircraft construction for interior fittings, flooring, and structural components.

How are honeycomb core panels used in marine applications?

Honeycomb core panels are used in boat building for interior fittings, hull construction, and structural components.

What are the applications of honeycomb core panels in construction?

Honeycomb core panels are used for wall cladding, roofing, partitions, and other structural elements in construction projects.

Are there other uses for honeycomb core panels?

Yes, honeycomb core panels are also used in the automotive industry, furniture manufacturing, and protective packaging.

Can you provide examples of real-life projects using honeycomb core panels?

Yes, notable projects include the Kings Domain Residential Tower, CTF Tower, Shenzhen Airport, Xi’an Airport, Zhuhai Library, The Parisian Macau, and Bantian International School.

How is the quality of honeycomb core panels ensured during production?

Manufacturers adhere to strict quality control measures, including ISO 9001 standards, and conduct regular laboratory testing.

Can honeycomb core panels be customized?

Yes, honeycomb core panels can be produced in various sizes and offer coating and surface options for customization.

What is the future outlook for honeycomb core panels?

With ongoing advancements in material science and manufacturing technologies, honeycomb core panels are expected to become lighter, stronger, and more sustainable.

What advantages do honeycomb core panels have over conventional materials?

Honeycomb core panels offer advantages such as lightweight construction, excellent impact resistance, and natural thermal insulation properties.