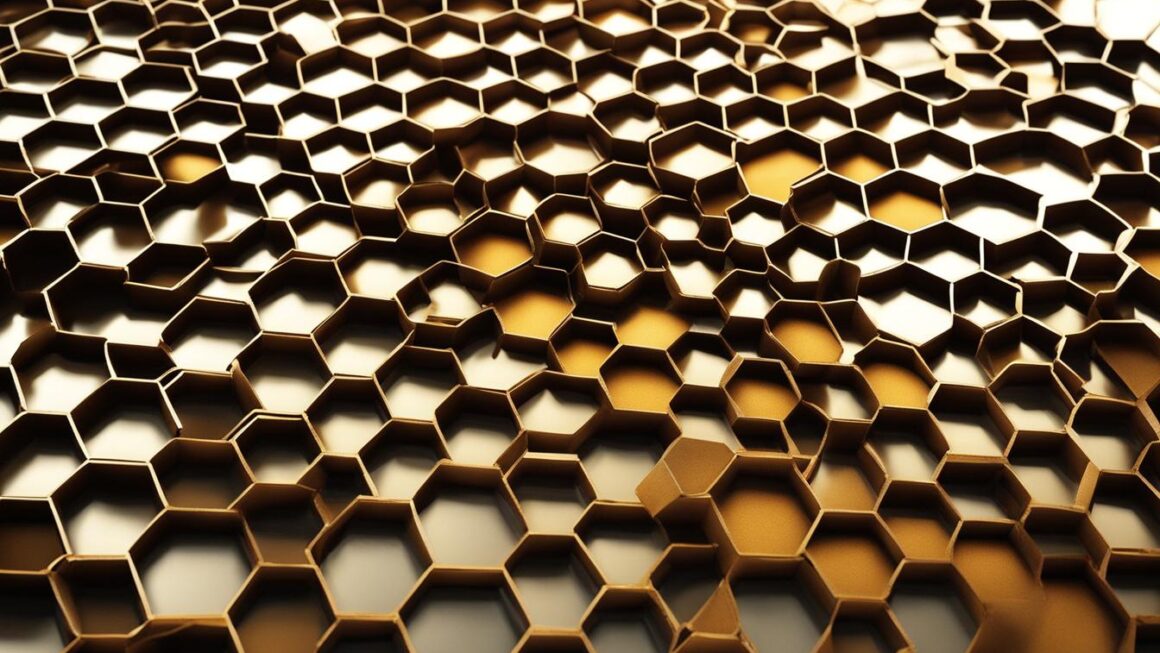

Honeycomb tables are essential for laser cutting as they provide stability and support for materials during the cutting process. They are ideal for cutting thin products or consumable sheets. The honeycomb structure allows the laser beam to pass through the material while evacuating vapors efficiently. Laser cut honeycomb panels are commonly used in woodworking and acrylic cutting, as they help to enhance the precision of cuts and reduce the risk of burn marks. Additionally, they provide improved airflow to remove dust and fumes, resulting in cleaner cuts.

Key Takeaways:

- Honeycomb tables provide stability and support for materials during laser cutting.

- Laser cut honeycomb panels enhance precision and reduce the risk of burn marks.

- Honeycomb structure allows efficient evacuation of vapors and improves airflow for cleaner cuts.

- They are commonly used in woodworking and acrylic cutting.

- Honeycomb tables are essential for optimizing precision cuts.

Benefits of Using Honeycomb for Laser Cutting

Honeycomb tables offer several advantages for laser cutting. Firstly, they provide a stable base for materials, ensuring precise and consistent cuts. They also help to reduce waste by preventing materials from shifting or warping during cutting. This improves the overall efficiency and productivity of laser cutting processes. Additionally, laser cut honeycomb material ensures excellent material preservation by eliminating burn marks and minimizing the build-up of dust and smoke. This results in a cleaner and higher-quality finished product.

Enhanced Stability and Precision

The honeycomb structure of laser cutting tables provides enhanced stability during the cutting process. It prevents materials from moving or vibrating, allowing for more precise and accurate cuts. This is especially important when working with delicate or thin materials that are prone to shifting. The stable base also minimizes the risk of misalignment, resulting in cleaner and more consistent cuts.

Reduced Waste and Improved Efficiency

By preventing materials from shifting or warping during cutting, honeycomb tables help to reduce waste. This is particularly beneficial when working with expensive or limited resources. The stable support provided by the honeycomb structure allows for optimized material utilization, maximizing efficiency and minimizing material loss. This leads to cost savings and improved productivity in laser cutting processes.

Enhanced Material Preservation

Laser cut honeycomb material offers excellent material preservation. The honeycomb structure allows for efficient evacuation of vapors, reducing the risk of burn marks and discoloration on the material. It also helps to minimize the build-up of dust and smoke, resulting in cleaner and higher-quality cuts. This is especially important when working with materials that require a pristine finish, such as acrylic or wood, as it ensures the final product meets the desired specifications.

Overall, honeycomb tables provide numerous benefits in laser cutting processes. They offer enhanced stability and precision, reduced waste, and improved material preservation. These advantages make honeycomb laser cutting services and laser cut honeycomb material a valuable choice for industries that require precision cutting and high-quality finished products.

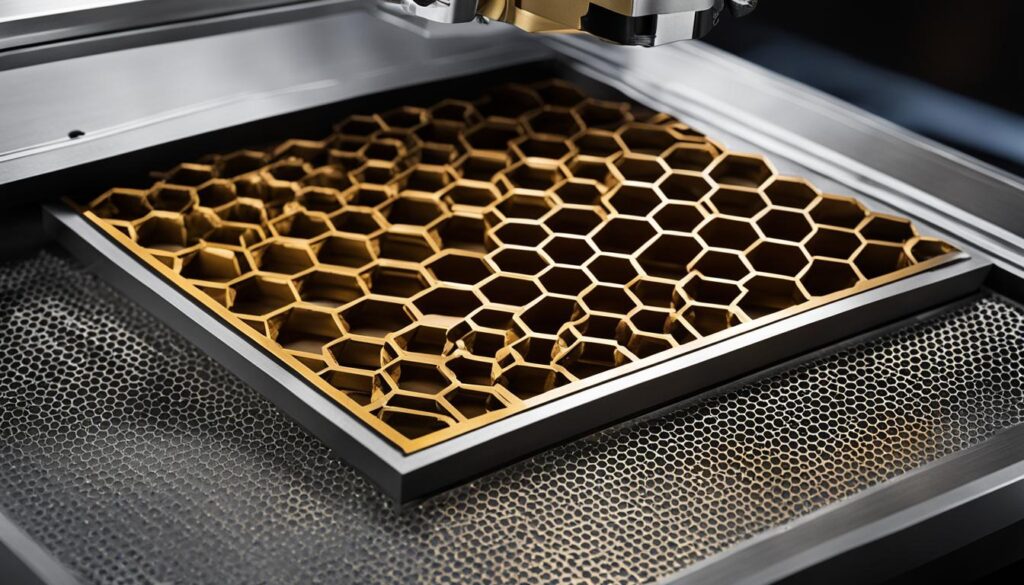

Types of Honeycomb Laser Cutting Solutions

When it comes to honeycomb laser cutting, there are various types of solutions available to cater to different needs and industries. One of the key components in honeycomb laser cutting is the honeycomb laser cutter itself. These machines are specifically designed to work with a honeycomb table, providing precise and accurate cutting capabilities for a wide range of materials.

In addition to the honeycomb laser cutter, another type of solution commonly used is laser cutting honeycomb boards. These boards are customizable to fit the specific requirements of different materials and projects. They provide the necessary support and airflow needed for optimal cutting results.

Whether you’re working with wood, leather, or plastics, honeycomb laser cutting solutions offer enhanced precision and efficiency. The honeycomb structure of the table allows for stable material support, ensuring consistent and clean cuts. It also helps to reduce waste by preventing materials from shifting or warping during the cutting process.

Benefits of Honeycomb Laser Cutting Solutions:

- Precise and accurate cuts

- Efficient material utilization

- Stable support for materials

- Reduction in waste

- Cleaner and higher-quality cuts

Honeycomb Laser Cutters vs. Other Cutting Methods:

| Honeycomb Laser Cutting | Other Cutting Methods | |

|---|---|---|

| Precision | High precision and accuracy | Depending on the method, varying levels of precision |

| Material Support | Stable support with reduced risk of shifting or warping | May require additional support or clamping |

| Efficiency | Efficient cutting with reduced waste | Potential for more waste due to material shifting |

| Cut Quality | Cleaner cuts with minimal burning or distortion | Potential for burning and distortion |

In conclusion, honeycomb laser cutting solutions offer a range of benefits and advantages for precision cutting. Whether you choose a honeycomb laser cutter or opt for laser cutting honeycomb boards, you can expect enhanced precision, reduced waste, and cleaner cuts. These solutions are widely used in industries such as woodworking, leathercrafting, and plastics cutting. By utilizing honeycomb laser cutting, you can achieve superior cutting results and elevate your production processes.

Customized Honeycomb Laser Cutting Solutions

Customized honeycomb laser cutting solutions offer a tailored approach to meet the unique requirements of different industries and applications. With customized designs, businesses can maximize precision and efficiency, resulting in high-quality cuts that align with specific project specifications. Whether it’s architectural designs, artwork, or industrial components, customized honeycomb laser cutting provides a comprehensive solution for optimal results.

By leveraging the benefits of customized honeycomb laser cutting, businesses can achieve superior accuracy and control in their cutting processes. These solutions enable the creation of personalized honeycomb designs that perfectly fit the materials being cut, ensuring stability and support during the laser cutting process. This customized approach minimizes the risk of errors or misalignments, resulting in cleaner and more precise cuts.

Customized honeycomb laser cutting solutions are particularly beneficial for industries that require intricate designs or precise measurements. The ability to tailor honeycomb designs for specific materials and projects allows for improved productivity and enhanced quality standards. With customized honeycomb laser cutting, businesses can confidently meet the demands of their unique applications and achieve exceptional cutting results.

Benefits of Customized Honeycomb Laser Cutting

Customized honeycomb laser cutting offers a range of benefits for businesses:

- Enhanced precision and accuracy in cuts

- Improved efficiency and productivity

- Reduced waste and material cost

- Minimized risk of burn marks or damage

By investing in customized honeycomb laser cutting solutions, businesses can optimize their cutting processes and achieve exceptional results that meet their specific needs and requirements.

Example of Customized Honeycomb Laser Cutting Solutions

To illustrate the versatility and applications of customized honeycomb laser cutting, here is an example:

| Industry | Application | Customized Solution |

|---|---|---|

| Architectural | Model Making | Precision-cut honeycomb panels for detailed architectural models |

| Art and Design | Acrylic Cutting | Custom honeycomb designs for intricate artwork and precise acrylic cuts |

| Manufacturing | Prototyping | Personalized honeycomb laser cutting for accurate and efficient prototyping of industrial components |

This example showcases how customized honeycomb laser cutting solutions cater to different industries and applications, providing tailored cutting capabilities that result in superior precision, quality, and efficiency.

The Importance of Honeycomb Laser Cutting in Various Industries

Honeycomb laser cutting solutions play a crucial role in a variety of industries, offering efficient and precise cutting capabilities. Let’s explore how honeycomb laser cutting benefits different sectors:

Woodworking

In woodworking, honeycomb laser cutting solutions enable intricate design work, precise cuts, and efficient material utilization. The stability provided by the honeycomb structure ensures consistent and accurate cutting, resulting in high-quality finished products. Whether it’s creating detailed furniture pieces or intricate decorative elements, honeycomb laser cutting enhances precision and productivity in the woodworking industry.

Leathercrafting

Honeycomb laser cutting is ideal for leathercrafting, as it ensures clean and precise cuts on various types of leather. The stability and support provided by the honeycomb table minimize material shifting, resulting in accurate and intricate designs. From custom leather accessories to footwear, honeycomb laser cutting solutions help craftsmen achieve exceptional precision and quality in their creations.

Textile Cutting

Textile cutting requires a versatile cutting solution that can handle different materials while maintaining speed and accuracy. Honeycomb laser cutting excels in this area, with its ability to cut diverse textiles without damaging protection layers. This technology offers fast, clean, and precise cutting, making it suitable for industries such as fashion, automotive, and home textiles.

Metal Engraving

In the metal engraving industry, honeycomb laser cutting is used for marking and engraving stainless steel and carbon steel. The precise cutting capabilities of honeycomb laser technology enable intricate designs and accurate marking on metal surfaces. This makes it a valuable tool for industries that require durable and high-quality engravings, such as jewelry manufacturing and industrial component production.

As we can see, honeycomb laser cutting solutions offer significant advantages across various industries. From enhancing precision in woodworking to enabling clean cuts in leathercrafting and providing fast and accurate textile cutting, honeycomb laser cutting is a valuable technology with diverse applications. Its ability to deliver precise and efficient cuts makes it an essential tool for industries that prioritize quality, productivity, and innovation.

Enhancing Precision with Honeycomb Laser Cutting

Honeycomb laser cutting is known for its ability to enhance precision in cutting processes. The stable support provided by the honeycomb structure ensures that materials remain in place during cutting, minimizing the risk of errors or misalignments. The improved airflow helps to remove debris and prevent accumulation, resulting in cleaner and more accurate cuts. Whether it’s for intricate designs or precise measurements, honeycomb laser cutting solutions offer superior precision and control.

When using a laser cutter with a honeycomb table, the materials being cut are supported evenly across the surface, preventing any deflection or warping. This stability is vital for achieving precise cuts and maintaining consistent dimensions throughout the entire cutting process. The honeycomb structure also allows for efficient evacuation of vapors, ensuring that the laser beam can pass through the material without interference.

With honeycomb laser cutting, the precision of cuts is further enhanced by the improved airflow. The honeycomb structure allows for efficient removal of dust and fumes, creating a cleaner working environment. This not only results in cleaner cuts but also ensures the longevity of the laser cutter and reduces the need for frequent cleaning and maintenance.

“Honeycomb laser cutting solutions offer precise and accurate cutting capabilities, making them ideal for industries that require high levels of precision. The stability and support provided by the honeycomb structure enhance the accuracy of cuts and reduce the risk of errors.” – Laser Cutting Expert

Whether you require precision laser cutting services for intricate designs, architectural models, or industrial components, honeycomb laser cutting solutions can meet your needs. The advanced technology and precise control provided by these solutions ensure that every cut is executed with the utmost accuracy and precision. With honeycomb laser cutting, you can achieve clean, precise, and professional results every time.

In summary, honeycomb laser cutting is a reliable and efficient method for enhancing precision in cutting processes. The stability and support provided by the honeycomb structure, combined with improved airflow, ensure cleaner and more accurate cuts. Whether you’re working on intricate designs or precise measurements, honeycomb laser cutting solutions offer superior precision and control. Choose the right honeycomb laser cutting solution for your specific needs, and elevate the precision of your cutting processes.

Advancements in Honeycomb Laser Cutting Technology

Laser cutting technology has made significant advancements in recent years, offering improved precision and efficiency for cutting a wide range of materials. Honeycomb laser cutting solutions have played a vital role in these advancements, providing enhanced support and stability during the cutting process.

One of the notable advancements in honeycomb laser cutting technology is the development of more efficient laser cutting machines. These machines are now capable of delivering highly precise cuts with faster processing times. Advanced control systems enable better customization and optimization of cutting parameters, allowing for increased accuracy and flexibility in various applications.

Laser cutting software has also seen significant improvements, providing enhanced design capabilities and improved workflow efficiency. With intuitive interfaces and powerful features, laser cutting software allows users to create intricate designs and easily translate them into precise cutting instructions. This streamlines the cutting process and ensures consistent, high-quality results.

Enhanced materials and coatings

Another area of advancement in honeycomb laser cutting technology is the development of new materials and coatings for honeycomb tables. These materials offer improved durability, heat resistance, and enhanced laser beam absorption, resulting in more precise and efficient cutting. Additionally, the coatings applied to honeycomb tables can reduce the risk of scratches and provide better adhesion, ensuring materials stay firmly in place during cutting.

| Advancements in Honeycomb Laser Cutting Technology | Benefits |

|---|---|

| More efficient laser cutting machines | – Faster processing times – Increased accuracy – Flexibility in various applications |

| Improved laser cutting software | – Enhanced design capabilities – Streamlined workflow – Consistent, high-quality results |

| Enhanced materials and coatings | – Improved durability, heat resistance – Enhanced laser beam absorption – Reduced risk of scratches |

These advancements in honeycomb laser cutting technology have revolutionized the precision and efficiency of laser cutting processes. Whether it’s for intricate designs, precise measurements, or clean cuts, businesses can rely on honeycomb laser cutting solutions to achieve optimal results. As technology continues to advance, we can expect even more innovative solutions that further elevate the capabilities and possibilities of laser cutting.

Choosing the Right Honeycomb Laser Cutting Solution

When it comes to honeycomb laser cutting, selecting the right solution is crucial for achieving optimal results. Whether you’re working with woodworking, leathercrafting, textiles, or metal engraving, finding a honeycomb laser cutting solution that aligns with your specific needs is essential.

A key consideration when choosing a honeycomb laser cutting solution is the type of materials you’ll be working with. Different materials have varying requirements, so it’s important to select a solution that can accommodate the specific characteristics of your materials.

Another crucial factor to consider is the desired precision and quality of your cuts. Honeycomb laser cutting provides enhanced stability and support, minimizing the risk of errors or misalignments. This ensures that you can achieve precise and accurate cuts, resulting in high-quality finished products.

Additionally, the size and configuration of the laser cutting bed should be taken into account. Laser cutting beds with honeycomb structures are available in various sizes, allowing you to choose one that suits the dimensions of your materials and project requirements.

Comparison of Honeycomb Laser Cutting Solutions

| Features | Standard Solution | Customized Solution |

|---|---|---|

| Precision | Offers excellent precision for general cutting needs. | Provides tailored precision for specific materials and projects. |

| Material Compatibility | Compatible with a wide range of materials. | Customized to suit the specific requirements of different materials. |

| Flexibility | Offers standard configurations and settings. | Allows for customization and optimization of cutting parameters. |

| Efficiency | Provides efficient cutting capabilities. | Maximizes efficiency with personalized cutting solutions. |

| Scalability | May not be suitable for large-scale projects. | Can be scaled up to accommodate large-scale cutting needs. |

By carefully considering these factors and comparing different honeycomb laser cutting solutions, you can choose the one that best meets your needs. Whether you opt for a standard solution or a customized one, honeycomb laser cutting offers enhanced precision, reduced waste, and improved productivity. With the right solution, you can achieve cleaner cuts and elevate the quality standards of your products.

Conclusion

Honeycomb for laser cutting is a crucial component in optimizing precision cuts. With its honeycomb structure, it offers numerous benefits that enhance cutting processes. Firstly, honeycomb tables provide enhanced precision by offering stability and support to materials during cutting. This stability ensures consistent and accurate cuts, reducing the risk of errors or misalignments.

In addition to precision, honeycomb laser cutting solutions also contribute to reduced waste and improved productivity. By preventing materials from shifting or warping during cutting, honeycomb tables help maximize material utilization and minimize scrap. This not only saves costs but also improves overall efficiency and productivity in laser cutting processes.

Moreover, honeycomb laser cutting solutions offer cleaner cuts by minimizing the build-up of dust and smoke. The honeycomb structure allows for improved airflow, removing debris and vapors efficiently. This results in higher-quality finished products with reduced burn marks and improved material preservation.

As laser cutting technology continues to advance, honeycomb tables and laser cutting machines provide superior precision and control. Businesses can achieve optimal cutting results by choosing the right honeycomb laser cutting solution that caters to their specific needs. This ensures elevated productivity and quality standards, making honeycomb for laser cutting a valuable tool across various industries and applications.

FAQ

What are honeycomb tables used for in laser cutting?

Honeycomb tables provide stability and support to materials during the laser cutting process. They are ideal for cutting thin products or consumable sheets.

What are the benefits of using honeycomb for laser cutting?

Honeycomb tables offer stability for precise and consistent cuts, reduce waste by preventing material shifting or warping, and ensure cleaner cuts with minimal burn marks and dust build-up.

What types of honeycomb laser cutting solutions are available?

There are honeycomb laser cutters designed specifically for cutting materials with honeycomb tables. Laser cutting honeycomb boards are also customizable to specific material and project needs.

Can honeycomb laser cutting solutions be customized?

Yes, customized honeycomb laser cutting solutions can be created to cater to the unique requirements of different industries and applications, providing tailored cutting capabilities for optimal results.

In which industries is honeycomb laser cutting important?

Honeycomb laser cutting plays a crucial role in woodworking, leathercrafting, textile cutting, and metal engraving industries, offering precise cuts and efficient material utilization.

How does honeycomb laser cutting enhance precision?

The stable support provided by honeycomb tables ensures materials remain in place during cutting, minimizing the risk of errors or misalignments. Improved airflow also helps to remove debris for cleaner and more accurate cuts.

What advancements are being made in honeycomb laser cutting technology?

Laser cutting machines are becoming more efficient and versatile, with advanced control systems and software for better customization and optimization of cutting parameters. New materials and coatings for honeycomb tables further enhance cutting precision and quality.

How can I choose the right honeycomb laser cutting solution?

When choosing a honeycomb laser cutting solution, consider the type of materials being cut, desired precision and quality, and specific requirements of the application. Select a honeycomb laser cutting solution that provides the necessary support, stability, and airflow for optimal cutting results.

What are the key takeaways about honeycomb for laser cutting?

Honeycomb for laser cutting is crucial in optimizing precision cuts, offering numerous benefits such as enhanced precision, reduced waste, improved productivity, and cleaner cuts. Honeycomb laser cutting solutions cater to various industries, providing customized and efficient cutting capabilities. As laser cutting technology advances, honeycomb tables and laser cutting machines offer superior precision and control.