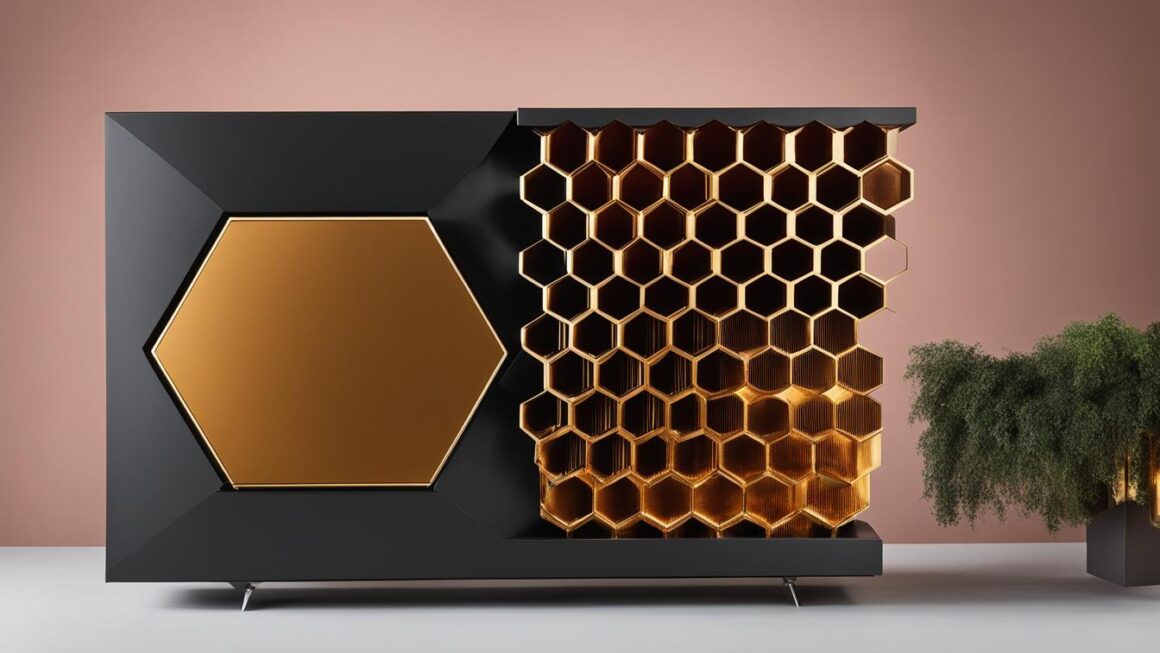

Honeycomb radiators are revolutionizing the world of radiator design, offering an innovative solution for efficient cooling and optimal performance. With their unique honeycomb core structure, these radiators provide enhanced heat transfer and thermal conductivity, making them ideal for a wide range of applications, including automotive and space systems.

Key Takeaways:

- Honeycomb radiators utilize a honeycomb core structure for efficient cooling and heat transfer.

- They offer superior heat dissipation and improved cooling efficiency compared to traditional radiator designs.

- The properties of honeycomb radiators include increased surface area, improved thermal conductivity, and lightweight design.

- They play a crucial role in the transcritical CO2 heat pump and space radiator systems.

- Honeycomb radiators can be integrated with controlled loop heat pipes for applications requiring controlled cooling.

The Properties and Advantages of Honeycomb Radiators

Honeycomb radiators offer several properties that make them highly advantageous for efficient cooling and heat transfer. The key to their effectiveness lies in their unique honeycomb core structure, which provides enhanced thermal conductivity and increased surface area. This results in improved heat dissipation and cooling efficiency compared to traditional radiator designs.

One of the main advantages of honeycomb radiators is their lightweight and compact design. This makes them ideal for applications where space and weight are crucial factors, such as automotive radiators. Their compact size allows for easy installation in vehicles without compromising on cooling performance.

Furthermore, honeycomb radiators have a higher heat transfer coefficient, meaning they can dissipate heat more effectively. This leads to improved overall performance and durability, making them the preferred choice for high-performance radiators.

Advantages of Honeycomb Radiators:

- Enhanced thermal conductivity

- Increased surface area for improved heat dissipation

- Compact and lightweight design

- Higher heat transfer coefficient

- Improved cooling efficiency and performance

In summary, honeycomb radiators offer exceptional properties and advantages that make them the preferred choice for efficient cooling and heat transfer. Their unique honeycomb core structure, combined with their compact and lightweight design, results in improved thermal conductivity, increased surface area for better heat dissipation, and higher heat transfer coefficient. These properties contribute to enhanced cooling efficiency, improved overall performance, and durability in various applications, making honeycomb radiators the ideal solution for high-performance radiators.

The Role of Honeycomb Radiators in the Transcritical CO2 Heat Pump

In the transcritical CO2 heat pump system, the gas cooler plays a crucial role in the overall thermal cycle and heat transfer performance. Honeycomb radiators have been adopted in the gas cooler of the transcritical CO2 heat pump due to their high heat transfer efficiency and strong pressure-bearing capacity. The honeycomb structure enhances heat transfer between the supercritical carbon dioxide (SCO2) and the cooling water, resulting in improved cooling efficiency and overall system performance.

Studies have shown that honeycomb radiators outperform traditional heat exchangers in terms of heat transfer characteristics and overall efficiency. The honeycomb core design provides a larger surface area for heat exchange, allowing for more effective cooling. Additionally, the thermal conductivity of the honeycomb material enhances the transfer of heat, ensuring optimal performance of the gas cooler.

With the adoption of honeycomb radiators in the gas cooler of transcritical CO2 heat pump systems, engineers can achieve higher heat transfer performance and more efficient cooling. This is crucial in applications where maintaining optimal temperatures is essential for the overall functionality and efficiency of the system.

The Role of Honeycomb Radiators in Transcritical CO2 Heat Pump Systems

Honeycomb radiators have proven to be highly efficient in the gas cooler of transcritical CO2 heat pump systems. Their unique design allows for enhanced heat transfer between the supercritical carbon dioxide and the cooling water, resulting in improved cooling efficiency. The high heat transfer efficiency of honeycomb radiators makes them an ideal choice for applications where heat dissipation is critical.

Furthermore, honeycomb radiators have a strong pressure-bearing capacity, ensuring their reliability and durability in demanding operating conditions. This is particularly important in transcritical CO2 heat pump systems, where the gas cooler is subjected to high pressures and temperature differentials.

| Advantages of Honeycomb Radiators in Transcritical CO2 Heat Pump Systems |

|---|

| Enhanced heat transfer efficiency |

| Improved cooling performance |

| High pressure-bearing capacity |

| Reliability and durability |

The use of honeycomb radiators in transcritical CO2 heat pump systems offers significant benefits in terms of heat transfer performance and overall system efficiency. As engineers continue to explore innovative solutions for efficient cooling, honeycomb radiators remain at the forefront of radiator technology.

Honeycomb Radiators for Space Radiators

Honeycomb radiators have also been applied in space radiator systems. These radiators, with their honeycomb panel design, provide a moderate temperature range, low-mass, and highly efficient cooling solution for space applications. Tests conducted on thin-wall honeycomb radiators with a hexagonal-cell size have shown excellent heat transfer performance and isothermal behavior throughout the surface. The use of honeycomb radiators in space applications ensures efficient and reliable heat dissipation, contributing to the overall success and functionality of space systems.

One key advantage of honeycomb radiators in space applications is their ability to provide efficient cooling performance while maintaining a lightweight design. The honeycomb structure allows for increased surface area, enhancing heat transfer and cooling efficiency. This is particularly important in space systems where weight and space constraints are critical factors. With honeycomb radiators, spacecraft can effectively dissipate heat generated by onboard systems, maintaining optimal operating temperatures and ensuring the reliability and functionality of the mission.

In addition to their efficient cooling capabilities, honeycomb radiators offer other advantages for space applications. Their isothermal behavior across the radiator’s surface ensures even heat distribution and minimizes thermal gradients, eliminating the risk of hotspots and potential damage to sensitive equipment. Furthermore, the honeycomb structure provides structural stability and pressure-bearing capacity, making them suitable for the extreme conditions of space environments.

Overall, the adoption of honeycomb radiators in space systems signifies a significant advancement in thermal management technology. These radiators offer efficient and reliable cooling solutions while meeting the stringent requirements of space missions. With ongoing research and development, honeycomb radiators continue to evolve, pushing the boundaries of efficient heat transfer and dissipation in space applications.

| Advantages of Honeycomb Radiators for Space Radiators | Benefits |

|---|---|

| Efficient Cooling Performance | Ensures optimal operating temperatures for onboard systems |

| Lightweight Design | Meets weight and space constraints in space applications |

| Isothermal Behavior | Prevents hotspots and thermal gradients, ensuring equipment integrity |

| Structural Stability | Withstands extreme conditions of space environments |

Table: Advantages of Honeycomb Radiators for Space Radiators

Honeycomb Radiators with Controlled Loop Heat Pipes

Honeycomb radiators, with their efficient heat transfer capabilities and high thermal conductivity, can be combined with controlled loop heat pipes (LHPs) to provide effective cooling in applications that require controlled cooling. The integration of honeycomb radiators with LHPs offers several advantages, including enhanced thermal performance and efficient heat dissipation. This combination is particularly beneficial for systems that require reliable and precise temperature control.

One of the key benefits of using honeycomb radiators with controlled LHPs is their high thermal conductivity. The honeycomb core structure, coupled with the use of carbon fiber reinforced plastics as face sheets, enables efficient heat transfer and improved cooling performance. This helps to maintain optimal operating temperatures and prevent overheating in critical applications.

Moreover, the lightweight design of honeycomb radiators makes them well-suited for space missions and other weight-sensitive applications. The use of carbon fiber reinforced plastics reduces the overall weight of the radiator while maintaining its structural integrity and thermal conductivity. This allows for efficient heat transfer without adding unnecessary weight to the system.

In summary, honeycomb radiators integrated with controlled loop heat pipes offer an effective solution for applications that require controlled cooling. With their high thermal conductivity, lightweight design, and efficient heat transfer capabilities, these radiators provide reliable and precise temperature control. Whether used in space systems or other demanding environments, honeycomb radiators with controlled LHPs are a valuable technology for optimizing cooling performance.

Advancements in Carbon Fiber Radiator Technology

The development of carbon fiber reinforced plastic (CFRP) face sheets has revolutionized the radiator industry. These face sheets, made from high-modular carbon fibers, offer high thermal conductivity, low specific mass, and excellent strength and stiffness. The use of CFRP face sheets in honeycomb radiators results in a lightweight design without compromising on heat transfer efficiency. The linear thermal expansion coefficient of CFRP is comparable to that of Aluminum alloys, making them compatible with metallic components in radiator systems. Carbon fiber radiators have undergone extensive testing and qualification, proving their reliability and performance in various applications.

Carbon fiber radiators with CFRP face sheets offer several advantages over traditional radiator designs. Firstly, they provide superior thermal conductivity, allowing for efficient heat transfer and cooling. This results in improved performance and durability of the radiator system. Additionally, the lightweight design of carbon fiber radiators reduces the overall weight of the system, making it ideal for applications where weight is a critical factor, such as aerospace or automotive industries.

Another benefit of carbon fiber radiators is their exceptional strength and stiffness. The high-modulus carbon fibers used in CFRP face sheets provide excellent structural integrity, ensuring the radiator can withstand the operational conditions and environmental stresses. This enhances the overall reliability and longevity of the radiator system.

“The use of carbon fiber reinforced plastics as face sheets in honeycomb radiators enhances thermal conductivity while reducing the overall weight of the radiator.”

Advantages of Carbon Fiber Radiators:

- High thermal conductivity

- Lightweight design

- Excellent strength and stiffness

- Reduced weight of the system

- Compatibility with metallic components

| Advantages | Traditional Radiators | Carbon Fiber Radiators |

|---|---|---|

| Thermal Conductivity | Lower | Higher |

| Weight | Heavier | Lighter |

| Strength | Lower | Higher |

Design Considerations for Honeycomb Radiators

When designing honeycomb radiators, several key considerations must be taken into account to ensure optimal performance and reliability. The thermal contact and mechanical interface between the honeycomb structure and metallic components, such as loop heat pipe condensers or heat pipes, play a crucial role in achieving efficient heat transfer. Different materials have varying linear thermal expansion coefficients, which can pose challenges in creating a reliable interface between the honeycomb structure and metallic parts.

Proper surface preparation and bonding techniques are essential to ensure optimal thermal contact and transfer efficiency. Engineers need to carefully select and evaluate the bonding materials to ensure compatibility with the honeycomb structure and metallic components. This ensures a reliable and durable interface that can withstand thermal cycling and mechanical stresses.

In addition to thermal considerations, the overall structural stability and pressure-bearing capacity of the honeycomb radiator must be carefully evaluated and designed. The honeycomb core must be able to withstand internal pressures and external forces without deformation or failure. This requires a thorough understanding of the mechanical properties of the honeycomb structure and appropriate structural design and analysis techniques.

Considerations for Thermal Expansion

One of the critical design considerations for honeycomb radiators is the thermal expansion coefficient. The thermal expansion of materials can lead to significant dimensional changes when subjected to different temperature environments. To ensure the structural integrity and performance of the radiator, the thermal expansion coefficients of the honeycomb core and metallic components must be carefully matched.

| Material | Thermal Expansion Coefficient (10^-6/°C) |

|---|---|

| Honeycomb Core | 6-8 |

| Aluminum Alloy | 22-24 |

| Copper | 16.6 |

Table: Thermal Expansion Coefficients of Honeycomb Core and Metallic Components

By selecting materials with similar thermal expansion coefficients, the risk of thermal stresses and potential structural damage can be minimized. This ensures that the honeycomb radiator maintains its structural integrity and thermal performance throughout its operating range.

In conclusion, designing honeycomb radiators involves careful consideration of thermal contact, mechanical interface, and thermal expansion coefficients. Ensuring proper bonding and thermal coupling, as well as matching thermal expansion coefficients, is crucial for achieving optimal performance and reliability. By addressing these design considerations, engineers can create honeycomb radiators that offer efficient heat transfer and cooling capabilities in a wide range of applications.

Honeycomb Radiators vs. Traditional Radiator Designs

Honeycomb radiators and traditional radiator designs have distinct differences in heat transfer efficiency and cooling performance. The unique honeycomb core structure of honeycomb radiators provides several advantages over traditional designs, making them the preferred choice for applications that require optimal cooling and performance.

One of the main advantages of honeycomb radiators is their enhanced heat transfer efficiency. The honeycomb core structure increases the surface area and improves the thermal conductivity, allowing for more effective heat dissipation and cooling. In contrast, traditional radiators may have limitations in terms of heat dissipation due to their design and material properties.

“Honeycomb radiators offer superior heat transfer characteristics, cooling efficiency, and overall performance.”

Furthermore, honeycomb radiators exhibit improved cooling performance. The honeycomb core structure allows for better airflow and thermal contact, resulting in efficient cooling of the radiator. This enhanced cooling performance contributes to better overall system performance and durability.

To showcase the differences between honeycomb radiators and traditional designs, the following table presents a comparison of their key features:

| Feature | Honeycomb Radiators | Traditional Radiators |

|---|---|---|

| Heat Transfer Efficiency | High | Moderate |

| Cooling Performance | Excellent | Good |

| Surface Area | Increased | Standard |

| Thermal Conductivity | Enhanced | Standard |

Based on the comparison, honeycomb radiators offer superior heat transfer efficiency and cooling performance compared to traditional radiator designs. These advantages make honeycomb radiators the preferred choice for applications that require efficient cooling and optimal performance.

Conclusion:

In summary, honeycomb radiators, with their unique honeycomb core structure, outperform traditional radiator designs in terms of heat transfer efficiency and cooling performance. Their enhanced heat dissipation capabilities and improved thermal conductivity make them the ideal choice for applications that prioritize efficient cooling and optimal performance.

Conclusion

Honeycomb radiators offer an innovative solution for efficient cooling and optimal performance in various applications, including automotive and space systems. The honeycomb core structure of these radiators enhances thermal conductivity and cooling efficiency, resulting in superior heat transfer characteristics compared to traditional radiator designs.

With their increased surface area and improved thermal conductivity, honeycomb radiators ensure efficient heat dissipation and reliable cooling performance. This makes them ideal for high-performance radiators where effective heat transfer is crucial. Additionally, honeycomb radiators are lightweight and compact, making them suitable for automotive applications where space and weight are important factors.

The integration of honeycomb radiators with controlled loop heat pipes and carbon fiber technology further enhances their thermal capabilities and lightweight design. This combination results in high thermal conductivity, efficient heat transfer, and reduced weight. As a result, honeycomb radiators are highly versatile and reliable options for applications that require controlled cooling and efficient heat dissipation.

As radiator technology continues to advance, honeycomb radiators remain at the forefront of efficient cooling solutions. With ongoing research and advancements, these radiators will continue to play a significant role in radiator design, offering high-performance cooling solutions for various industries.

FAQ

What is a honeycomb radiator?

A honeycomb radiator is a radiator design that utilizes a honeycomb core to enhance cooling efficiency and thermal conductivity.

Why are honeycomb radiators advantageous for heat transfer and cooling?

Honeycomb radiators have increased surface area and improved thermal conductivity, resulting in efficient cooling and heat dissipation. They are also lightweight and compact, making them ideal for automotive applications where space and weight are crucial factors.

What role do honeycomb radiators play in the transcritical CO2 heat pump system?

Honeycomb radiators are used in the gas cooler of the transcritical CO2 heat pump due to their high heat transfer efficiency and strong pressure-bearing capacity. The honeycomb structure enhances heat transfer between the supercritical carbon dioxide (SCO2) and the cooling water, resulting in improved cooling efficiency and overall system performance.

How are honeycomb radiators applied in space radiator systems?

Honeycomb radiators with their honeycomb panel design provide a moderate temperature range, low-mass, and highly efficient cooling solution for space applications. They ensure efficient and reliable heat dissipation, contributing to the overall success and functionality of space systems.

Can honeycomb radiators be integrated with controlled loop heat pipes?

Yes, honeycomb radiators can be integrated with controlled loop heat pipes to offer high thermal conductivity and efficient heat transfer capabilities. This combination provides effective cooling for storage batteries and operating systems of spacecraft.

What advancements have been made in carbon fiber radiator technology?

Carbon fiber reinforced plastic (CFRP) face sheets have revolutionized the radiator industry. They offer high thermal conductivity, low specific mass, excellent strength, and stiffness. The use of CFRP face sheets in honeycomb radiators results in a lightweight design without compromising on heat transfer efficiency.

What design considerations should be taken into account when designing honeycomb radiators?

Special attention must be given to the thermal contact and mechanical interface between the honeycomb structure and metallic components. Different materials have different linear thermal expansion coefficients, which can pose challenges. Proper surface preparation and bonding techniques are crucial for achieving optimal thermal contact and transfer efficiency.

How do honeycomb radiators compare to traditional radiator designs?

Honeycomb radiators outperform traditional designs in terms of heat transfer characteristics, cooling efficiency, and overall performance. The honeycomb core structure provides a larger surface area and enhanced thermal conductivity, resulting in improved heat transfer efficiency and cooling performance.

In what applications are honeycomb radiators commonly used?

Honeycomb radiators are widely used in automotive radiators, space systems, and other high-performance radiators where efficient cooling and heat transfer are crucial.