When it comes to sealing technology, honeycomb seals have emerged as a game-changer in various industrial applications. Their advanced design and sealing solutions make them highly effective in aerospace applications, gas turbine engines, and high-temperature environments. The unique honeycomb structure of these seals not only improves efficiency but also reduces leakage, ensuring durability and superior performance even in the most demanding conditions.

Key Takeaways:

- Honeycomb seals offer advanced sealing solutions for industrial applications.

- They excel in aerospace applications, gas turbine engines, and high-temperature environments.

- The honeycomb structure improves efficiency and reduces leakage.

- These seals are known for their durability and superior performance.

- Honeycomb seals play a crucial role in enhancing overall efficiency and reliability in industrial equipment.

The Advantages of Honeycomb Seals

Honeycomb seals offer several advantages over traditional sealing technologies. Their honeycomb structure provides increased efficiency by reducing leakage between components. This helps to optimize the performance of industrial equipment, such as gas turbine engines, by minimizing energy losses. Additionally, honeycomb seals are highly durable, ensuring long-lasting operation even in harsh environments. This combination of efficiency and durability makes honeycomb seals an excellent choice for enhancing overall performance.

One of the key benefits of honeycomb seals is their ability to improve efficiency in industrial applications. The unique honeycomb structure creates a labyrinth-type seal, which optimizes the flow of fluids or gases within the system. This reduces leakage and minimizes energy losses, resulting in improved overall efficiency. By enhancing the sealing capabilities of industrial equipment, honeycomb seals contribute to energy savings and increased productivity.

The durability and performance of honeycomb seals are unmatched. These seals are designed to withstand demanding operating conditions, including high temperatures, pressures, and mechanical stresses. They undergo rigorous testing to ensure their reliability and long-lasting operation. Honeycomb seals are made from materials that can withstand harsh environments while maintaining their sealing capabilities. This durability and performance make honeycomb seals a trusted choice for critical industrial applications.

Honeycomb seals provide a range of advantages that make them superior to traditional sealing technologies. Their unique honeycomb structure reduces leakage and improves overall efficiency, while their durability ensures reliable operation even in harsh environments. With their ability to enhance performance and contribute to energy savings, honeycomb seals are a valuable asset in various industrial applications.

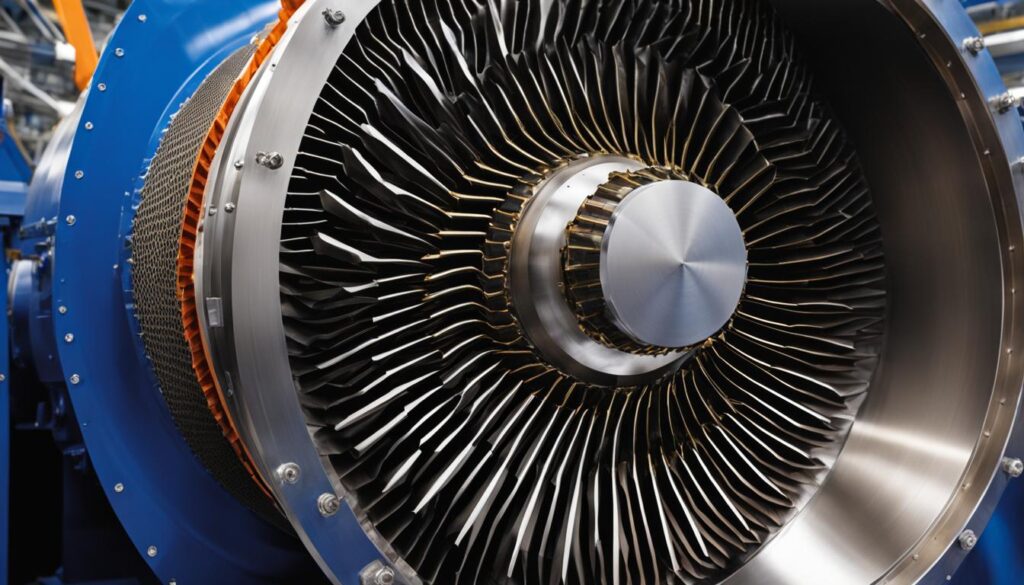

Honeycomb Seals in Aerospace Applications

Honeycomb seals are widely utilized in the aerospace industry, specifically in gas turbine engines that power aircraft propulsion systems. These seals play a crucial role in improving efficiency and reducing leakage within various components of the engine, such as the compressor and turbine stages. By minimizing energy losses and optimizing airflow, honeycomb seals contribute to enhanced overall performance and reliability in aircraft engines.

One of the key benefits of using honeycomb seals in the aerospace industry is the significant improvement in efficiency. The unique honeycomb structure of these seals creates a labyrinth-type seal, which effectively minimizes leakage and optimizes the flow of fluids or gases. This optimization results in reduced energy losses, leading to improved fuel efficiency and increased power output.

Furthermore, honeycomb seals offer enhanced sealing capabilities that are crucial for safe and efficient flight. They ensure that the engine operates with minimal leakage, maximizing the efficiency of the propulsion system and reducing the risk of performance issues. With their ability to withstand high temperatures and pressures, honeycomb seals provide reliable sealing solutions for the demanding conditions experienced in aerospace applications.

Benefits of Honeycomb Seals in Aerospace Applications

- Improved efficiency by minimizing leakage and reducing energy losses.

- Enhanced overall performance and reliability of aircraft engines.

- Optimized airflow for increased fuel efficiency and power output.

- Effective sealing capabilities for safe and efficient flight.

- Durable construction to withstand high temperatures and pressures.

Overall, honeycomb seals have become indispensable in the aerospace industry due to their ability to enhance efficiency, improve performance, and ensure reliable operation in gas turbine engines. The aerospace sector relies on the advanced sealing capabilities of honeycomb seals to achieve optimal efficiency and maintain safe and efficient flight.

Honeycomb Seals for High-Temperature Environments

Honeycomb seals are well-suited for high-temperature applications, offering exceptional thermal stability and thermal shock resistance. These seals are specifically designed to withstand extreme temperatures without compromising their sealing capabilities. The honeycomb structure of the seals provides excellent thermal insulation, minimizing heat transfer and ensuring the integrity of the seal even under demanding conditions.

One of the key advantages of honeycomb seals in high-temperature environments is their ability to maintain sealing efficiency and performance. They are engineered to resist thermal stresses and fluctuations, ensuring reliable operation in harsh industrial settings. By effectively sealing components and minimizing leakage, honeycomb seals contribute to the overall efficiency and safety of high-temperature applications.

Table:

| Honeycomb Seal Characteristics | Benefits |

|---|---|

| Thermal stability | Allows seals to withstand high temperatures without degradation |

| Thermal shock resistance | Protects seals from sudden temperature changes and prevents failure |

| High-temperature insulation | Minimizes heat transfer, ensuring efficient sealing in extreme conditions |

| Durable performance | Ensures reliable operation and long-lasting functionality |

Honeycomb seals are widely used in industries such as aerospace, power generation, and oil and gas, where high-temperature environments are prevalent. Their exceptional thermal stability and thermal shock resistance make them a trusted choice for sealing critical components in these demanding applications.

The Technology Behind Honeycomb Seals

Honeycomb seals incorporate advanced sealing technology to achieve superior performance in various industrial applications. Engineers leverage design optimization and fluid dynamics to create innovative solutions that minimize leakage and optimize airflow. Through computational modeling and advanced testing techniques, honeycomb seals undergo continuous development to enhance their sealing capabilities.

The key to the effectiveness of honeycomb seals lies in their unique honeycomb structure, which creates a labyrinth-type seal. This design maximizes the efficiency of fluid or gas flow within the system, reducing leakage and minimizing energy losses. By optimizing airflow, honeycomb seals contribute to improved overall efficiency and performance, making them an ideal choice for industrial applications.

“The honeycomb structure of these seals allows for the optimization of fluid dynamics, resulting in reduced leakage and improved overall performance.”

The technology behind honeycomb seals enables engineers to continuously refine and optimize their design. By considering factors such as fluid dynamics and sealing efficiency, engineers can create seals that are tailored to specific industrial applications. Ongoing research and development in honeycomb seal technology ensure that these advanced solutions meet the evolving needs of various industries.

| Advantages of Honeycomb Seals | Technology Behind Honeycomb Seals | Aerospace Applications of Honeycomb Seals |

|---|---|---|

| Increased efficiency | Design optimization | Gas turbine engines |

| Reduced leakage | Fluid dynamics | Aircraft propulsion systems |

| Durability and reliability | Continuous development | Enhanced efficiency |

Honeycomb seals are the result of advanced sealing technology and design optimization, driven by a deep understanding of fluid dynamics. With their ability to reduce leakage and improve efficiency, these seals offer advanced solutions for diverse industrial applications. The continuous development and refinement of honeycomb seal technology ensure that they remain at the forefront of sealing technology, delivering reliable performance in a range of industries.

Honeycomb Seals for Improved Efficiency

Honeycomb seals are highly effective in improving efficiency in industrial applications. These seals utilize a unique honeycomb structure that optimizes flow and reduces leakage, resulting in significant energy savings. By creating a labyrinth-type seal, honeycomb seals minimize the escape of fluids or gases, ensuring that equipment operates at peak efficiency.

Flow optimization is a key advantage of honeycomb seals. Their intricate design promotes smooth and uniform airflow, reducing turbulence and pressure losses. This not only enhances efficiency but also improves the overall performance of industrial equipment. With reduced leakage, honeycomb seals enable precise control of fluids or gases, resulting in enhanced productivity and cost savings.

The energy savings achieved through the use of honeycomb seals are substantial. By minimizing leakage and optimizing fluid dynamics, these seals reduce energy losses, which can have a significant impact on operating costs. In addition to cost savings, the improved efficiency resulting from the use of honeycomb seals contributes to a more sustainable and environmentally friendly operation.

Benefits of Honeycomb Seals for Improved Efficiency:

- Optimized flow and reduced leakage

- Enhanced performance and productivity

- Significant energy savings

- Improved control and precision

- Cost-effective and environmentally friendly operation

“The use of honeycomb seals has revolutionized industrial efficiency by minimizing leakage and optimizing fluid dynamics.”

| Application | Efficiency Improvement | Energy Savings |

|---|---|---|

| Aerospace | Reduction in leakage for improved engine performance | Reduced fuel consumption and lower emissions |

| Power Generation | Enhanced turbine efficiency for increased power output | Lower energy costs and reduced environmental impact |

| Oil and Gas | Improved sealing efficiency for enhanced equipment performance | Reduced energy consumption and improved safety |

In summary, honeycomb seals provide a highly effective solution for improving efficiency in industrial applications. Their unique honeycomb structure enables flow optimization, reduces leakage, and results in significant energy savings. With their ability to enhance performance, control, and precision, honeycomb seals offer a cost-effective and sustainable way to optimize industrial equipment.

The Durability and Performance of Honeycomb Seals

Honeycomb seals are widely recognized for their exceptional durability and high-performance capabilities in various industrial applications. These seals are specifically designed to withstand demanding operating conditions, including extreme temperatures, pressures, and mechanical stresses. With rigorous testing and advanced engineering, honeycomb seals ensure reliable and long-lasting operation, making them a trusted choice for critical industrial equipment.

The durability of honeycomb seals stems from their robust construction and materials that are carefully selected to withstand harsh environments. These seals are engineered to maintain their sealing capabilities even in the face of intense heat, pressure, and mechanical vibrations. By enduring challenging conditions, honeycomb seals contribute to the overall reliability and longevity of industrial systems.

The exceptional performance of honeycomb seals is a result of their advanced design features and sealing capabilities. The unique honeycomb structure optimizes fluid flow and minimizes leakage between components, enhancing overall system efficiency. This improved efficiency translates into energy savings, reduced maintenance requirements, and optimized performance for industrial equipment.

Honeycomb seals offer reliable and long-lasting operation, which is crucial for industries where downtime can result in significant financial losses and safety risks. The ability to withstand extreme conditions and maintain their sealing efficiency over time makes honeycomb seals an excellent choice for critical applications.

Durability vs. Performance: A Comparative Analysis

| Criteria | Durability | Performance |

|---|---|---|

| Resistance to extreme temperatures | Excellent | Excellent |

| Resistance to high pressures | Excellent | Excellent |

| Resistance to mechanical stresses | Excellent | Excellent |

| Leakage prevention | Superior | Superior |

This table showcases the remarkable durability and performance of honeycomb seals. It illustrates how honeycomb seals excel in various criteria, including their ability to withstand extreme temperatures, high pressures, and mechanical stresses. Additionally, honeycomb seals outperform traditional sealing technologies in terms of leakage prevention, ensuring superior reliability and performance.

Honeycomb Seals in Gas Turbine Engines

Honeycomb seals play a crucial role in ensuring the optimal performance of gas turbine engines. These engines rely on efficient sealing to minimize leakage and maximize power output. Honeycomb seals, with their unique honeycomb structure, are specifically designed to meet the demanding sealing requirements of gas turbine engines, contributing to increased performance and reduced emissions.

The honeycomb structure of these seals creates a labyrinth-type seal, which effectively minimizes leakage between components. This improves the overall efficiency of the gas turbine engine by optimizing airflow and reducing energy losses. By reducing leakage, honeycomb seals enhance the performance of the engine, resulting in increased power output.

In addition to improving performance, honeycomb seals also play a vital role in reducing emissions. By minimizing leakage, these seals help to maintain proper combustion within the engine, leading to cleaner exhaust gases. This is particularly important in today’s environmentally conscious manufacturing industries, where reducing emissions is a top priority.

Advantages of Honeycomb Seals in Gas Turbine Engines

Honeycomb seals offer several advantages when used in gas turbine engines:

- Improved sealing efficiency: The honeycomb structure reduces leakage between components, improving overall efficiency.

- Increased performance: By minimizing leakage and optimizing airflow, honeycomb seals contribute to increased power output.

- Reduced emissions: Proper sealing helps maintain proper combustion, resulting in cleaner exhaust gases.

- Long-lasting operation: Honeycomb seals are designed to withstand the demanding operating conditions of gas turbine engines, ensuring reliable and durable performance.

With their advanced sealing capabilities and numerous advantages, honeycomb seals have become an indispensable component in gas turbine engines. These seals not only enhance performance and efficiency but also contribute to reducing emissions, making them an essential technology for the future of sustainable energy production.

Honeycomb Seal Technology in Industrial Applications

Honeycomb seal technology has emerged as a game-changer in various industrial sectors, offering advanced designs and sealing solutions for a wide range of applications. The unique honeycomb structure of these seals allows for improved sealing efficiency, reduced leakage, and enhanced overall performance. With their versatile applications, honeycomb seals have become an indispensable component in industries such as power generation, oil and gas, chemical processing, and more.

One of the key advantages of honeycomb seal technology is its ability to provide efficient sealing capabilities in diverse industrial environments. These seals are designed to withstand challenging operating conditions, ensuring reliable and safe operation. By employing advanced materials and design optimization techniques, honeycomb seals offer superior durability and performance, making them well-suited for demanding industrial applications.

Moreover, honeycomb seals are known for their versatility, as they can be tailored to meet the specific sealing requirements of different industrial processes. Whether it’s high-temperature environments, corrosive substances, or extreme pressure differentials, honeycomb seals can be customized to provide optimal sealing solutions. This adaptability makes honeycomb seal technology a preferred choice for industries seeking reliable and efficient sealing solutions.

The Advantages of Honeycomb Seal Technology in Industrial Applications

- Enhanced sealing efficiency and reduced leakage

- Superior durability and performance in challenging operating conditions

- Versatile applications across various industrial sectors

- Customizable solutions to meet specific sealing requirements

With its advanced designs, sealing efficiency, and versatility, honeycomb seal technology continues to revolutionize industrial applications. As industries strive for improved efficiency, reliability, and safety, honeycomb seals play a crucial role in ensuring optimal performance and reducing downtime. The future of industrial sealing lies in the innovative capabilities of honeycomb seal technology, offering reliable sealing solutions for a wide range of industrial applications.

Conclusion

In conclusion, honeycomb seals have emerged as highly efficient and reliable sealing solutions for a wide range of industrial applications. The unique honeycomb structure of these seals improves sealing efficiency by reducing leakage and optimizing airflow. This leads to enhanced overall performance and increased energy savings in industrial equipment.

With their exceptional durability and ability to withstand harsh environments, honeycomb seals prove to be a trusted choice for critical applications. Whether it’s in aerospace industries, gas turbine engines, or high-temperature environments, these seals demonstrate their reliability and long-lasting operation.

As technology continues to advance, honeycomb seals will continue to play a crucial role in enhancing the efficiency and reliability of industrial equipment. Their versatile applications across various sectors, such as power generation, oil and gas, and chemical processing, make them an invaluable sealing solution for different industries.

FAQ

What are the advantages of honeycomb seals?

Honeycomb seals offer increased efficiency by reducing leakage and enhancing overall performance. They are highly durable, ensuring long-lasting and reliable operation.

In which industries are honeycomb seals commonly used?

Honeycomb seals are widely used in aerospace, power generation, oil and gas, chemical processing, and more.

How do honeycomb seals improve efficiency in gas turbine engines?

Honeycomb seals minimize leakage and optimize airflow, resulting in increased power output and reduced emissions.

Are honeycomb seals suitable for high-temperature environments?

Yes, honeycomb seals are designed to withstand extreme temperatures and provide thermal insulation to maintain their sealing capabilities.

What is the technology behind honeycomb seals?

Honeycomb seals incorporate advanced sealing technology, including design optimization and fluid dynamics, to achieve superior performance.

How do honeycomb seals contribute to energy savings?

Honeycomb seals reduce leakage and minimize energy losses, resulting in improved overall efficiency and increased productivity.

Are honeycomb seals durable and reliable?

Yes, honeycomb seals are known for their exceptional durability and performance, making them a trusted choice for critical industrial applications.

Can honeycomb seals be used in aerospace applications?

Yes, honeycomb seals play a crucial role in aerospace, particularly in gas turbine engines used for aircraft propulsion systems.

What makes honeycomb seal technology versatile?

Honeycomb seal technology offers advanced designs and sealing solutions, making it suitable for various industrial applications.

How do honeycomb seals enhance efficiency and reliability in industrial applications?

Honeycomb seals improve efficiency by reducing leakage and optimizing airflow, while their durability ensures long-lasting and reliable operation.