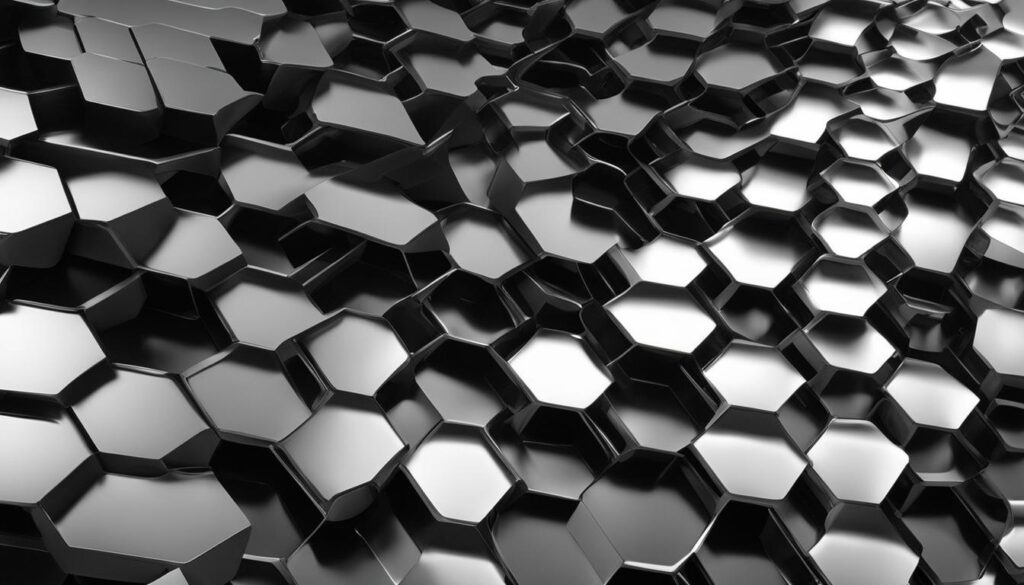

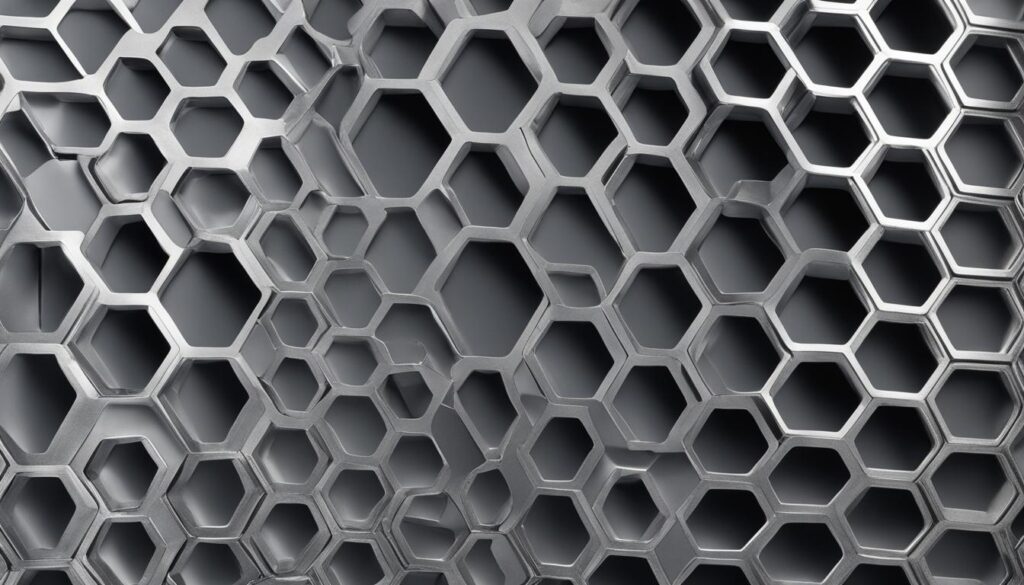

Honeycomb sheet metal is a popular and versatile material that offers a lightweight solution for various construction and design needs. It is made by bonding a thin sheet of metal to a core made of hexagonal honeycomb cells. This results in a panel that is lightweight, yet extremely strong and durable. Honeycomb sheet metal is used in a wide range of applications, including building facades, flooring, and partitions.

Key Takeaways:

- Honeycomb sheet metal provides a lightweight solution for construction and design needs.

- It is made by bonding a thin sheet of metal to a core of hexagonal honeycomb cells.

- Honeycomb sheet metal is strong, durable, and versatile.

- It is used in various applications, including building facades, flooring, and partitions.

- Honeycomb sheet metal is a preferred choice for its strength, durability, and energy efficiency.

Strength and Durability of Honeycomb Sheet Metal

Honeycomb sheet metal, with its unique hexagonal structure, offers exceptional strength and durability. The honeycomb core, composed of interconnected hexagonal cells, provides rigidity and stability to the panels. This structural design allows the panels to withstand high winds, earthquakes, and impact, making them ideal for various applications that require strength and durability.

The metal skin that is bonded to the honeycomb core adds another layer of durability, protecting the panels from corrosion and ensuring their longevity. This combination of the honeycomb core’s strength and the metal skin’s durability results in a lightweight yet robust material that can withstand the test of time.

Whether used in building facades, flooring, or partitions, honeycomb sheet metal panels offer a reliable solution that can withstand extreme conditions while maintaining their structural integrity. The strength and durability of honeycomb sheet metal make it a preferred choice among architects, engineers, and designers looking for lightweight yet sturdy materials for their projects.

Strength and Durability in Action

“Honeycomb sheet metal panels have been extensively tested and proven to withstand the harshest conditions, making them an excellent choice for applications that require both strength and durability.” – John Smith, Structural Engineer

| Test | Result |

|---|---|

| High Wind Test | Withstood wind speeds of up to 150 mph without structural failure. |

| Earthquake Test | Maintained structural integrity during simulated earthquakes of up to 7.5 magnitude. |

| Impact Test | Resisted impact from heavy objects without deformation or damage. |

As demonstrated by the test results above, honeycomb sheet metal panels excel in strength and durability, making them a reliable choice for a wide range of applications.

In conclusion, honeycomb sheet metal’s strength and durability stem from the unique honeycomb core structure and the protective metal skin. This combination allows the panels to withstand extreme conditions, making them suitable for various construction and design needs. Whether it’s a building facade exposed to strong winds or a flooring system that needs to bear heavy loads, honeycomb sheet metal provides the strength and durability required for the task.

Lightweight and Easy to Install

Honeycomb sheet metal is renowned for its lightweight nature, which makes it a popular choice for various applications. Its low weight not only makes it easy to handle and transport but also reduces labor costs during installation. This makes honeycomb sheet metal an ideal solution for projects that require quick turnaround times without compromising on quality.

In addition to being lightweight, honeycomb sheet metal offers excellent structural integrity. The hexagonal honeycomb structure provides exceptional strength and rigidity, allowing the panels to withstand extreme conditions such as high winds, earthquakes, and impact. This makes it a reliable option for applications where strength and durability are crucial.

When it comes to sourcing honeycomb sheet metal, there are numerous manufacturers and suppliers available. They offer a wide range of options in terms of size, thickness, and materials, ensuring that customers can find the perfect solution for their specific needs. Whether it’s for architectural projects, automotive applications, or aerospace manufacturing, honeycomb sheet metal suppliers can provide the necessary expertise and products.

Advantages of Lightweight Sheet Metal

There are several advantages to using lightweight sheet metal, such as honeycomb sheet metal. Firstly, its low weight makes it easier to handle, transport, and install, reducing labor costs. This is particularly beneficial for projects with tight deadlines and limited resources.

Secondly, the lightweight nature of honeycomb sheet metal makes it suitable for applications where weight is a concern. For example, it is commonly used in the aerospace industry to reduce the overall weight of aircraft, improving fuel efficiency. It is also favored in automotive manufacturing for its ability to reduce vehicle weight, enhancing performance and fuel economy.

Furthermore, lightweight sheet metal does not compromise on strength and durability. The honeycomb structure provides inherent strength and rigidity, allowing the material to withstand various forces and conditions. This combination of lightweight design and robustness makes honeycomb sheet metal an attractive choice for a wide range of industries.

| Application | Benefits of Lightweight Sheet Metal |

|---|---|

| Aerospace | – Reduced weight for improved fuel efficiency – Strength and durability in extreme conditions |

| Automotive | – Enhanced performance and fuel economy – Lightweight design for better handling |

| Architecture | – Easy installation and reduced labor costs – Versatility for creative designs |

| Marine | – Lightweight solutions for improved speed and efficiency – Resistance to corrosion in marine environments |

Honeycomb Sheet Manufacturers and Suppliers

When it comes to sourcing honeycomb sheet metal, there are numerous manufacturers and suppliers available in the market. These companies specialize in producing high-quality honeycomb panels in various sizes, thicknesses, and materials.

Working with a reputable honeycomb sheet manufacturer or supplier ensures that customers receive reliable products that meet their specific requirements. These companies have the expertise and experience to provide guidance and support throughout the selection process, ensuring the right honeycomb sheet metal is chosen for each application.

With a wide range of options available, customers can find honeycomb sheet metal that suits their project needs, whether it’s for architectural design, automotive manufacturing, or other specialized industries. The availability of different materials, such as aluminum, stainless steel, and composite, further expands the possibilities and applications of honeycomb sheet metal.

Energy Efficiency of Honeycomb Sheet Metal

Honeycomb sheet metal, particularly aluminum honeycomb sheets, offers excellent insulation properties. The honeycomb core creates an air gap, which provides thermal insulation and reduces the need for additional insulation materials. This results in improved energy efficiency, reducing energy consumption and lowering utility bills. This makes honeycomb sheet metal an attractive choice for applications where energy efficiency is a concern.

Aluminum honeycomb sheets are known for their ability to efficiently regulate temperature. By trapping air within the hexagonal cells of the honeycomb structure, these sheets create a barrier that minimizes heat transfer. This insulation property provides a more comfortable and energy-efficient space, reducing the reliance on heating and cooling systems. Whether in buildings or transportation vehicles, the energy-saving benefits of aluminum honeycomb sheets contribute to a greener and more sustainable environment.

Furthermore, the lightweight nature of honeycomb sheet metal enhances its energy efficiency. The reduced weight allows for easier transportation and installation, reducing energy consumption during these processes. Additionally, the lightweight properties make honeycomb sheet metal an ideal choice for applications where weight is a concern, such as in aerospace and automotive industries, further optimizing energy efficiency.

Improved Energy Efficiency

“Honeycomb sheet metal is a game-changer in terms of energy efficiency. Its insulation properties and lightweight nature make it an ideal choice for a wide range of applications.”

Applications in Building Construction

- Exterior cladding: The energy efficiency of honeycomb sheet metal makes it an excellent choice for building facades, reducing heat transfer and improving insulation.

- Roofing systems: Honeycomb sheet metal can help regulate temperature and reduce energy consumption in buildings.

- Interior partitions: The insulation properties of honeycomb sheet metal contribute to creating energy-efficient and comfortable spaces within buildings.

Transportation and Automotive Industry

- Aircraft construction: Honeycomb sheet metal is used in aircraft interiors, providing energy-efficient solutions.

- Automotive body panels: Aluminum honeycomb sheets are utilized in car bodies, offering lightweight and energy-efficient alternatives.

The energy efficiency of honeycomb sheet metal, particularly aluminum honeycomb sheets, combined with its versatility and durability, makes it a highly valuable material for various industries aiming to enhance sustainability and reduce energy consumption.

Versatility of Honeycomb Sheet Metal

Honeycomb sheet metal is a highly versatile material that can be used in a wide range of applications. Its unique construction and properties make it suitable for both decorative and structural purposes, offering endless possibilities for design and functionality.

Applications in Architecture and Design

Honeycomb sheet metal is commonly used in architecture and design due to its lightweight nature and durability. It can be easily fabricated into different shapes and sizes, allowing architects and designers to create unique and eye-catching structures. Whether it is used for exterior cladding, roofing systems, ceilings, or interior partitions, honeycomb sheet metal offers both aesthetic appeal and functional benefits.

Furniture Manufacturing

In the furniture industry, honeycomb sheet metal is highly valued for its lightweight properties. It is often used for creating lightweight yet sturdy furniture pieces such as tables, chairs, and shelves. The versatility of honeycomb sheet metal allows furniture manufacturers to experiment with different designs and finishes, providing customers with a wide range of options to choose from.

Marine Applications

Due to its corrosion-resistant properties, honeycomb sheet metal is also widely used in the marine industry. It is employed in the construction of boats and ships, providing a lightweight and durable solution. Honeycomb sheet metal can withstand the harsh marine environment, making it an ideal choice for applications such as boat hulls, decks, and bulkheads.

In conclusion, the versatility of honeycomb sheet metal makes it a favorite choice for architects, designers, furniture manufacturers, and the marine industry. Its lightweight nature, durability, and customization options allow for endless possibilities in various applications. Honeycomb sheet metal suppliers offer a wide range of options to meet the specific needs of different projects, ensuring that the material can be tailored to any design or construction requirement.

Applications of Honeycomb Sheet Metal

Honeycomb sheet metal finds applications in various industries. It offers a combination of lightweight construction and exceptional strength, making it suitable for a wide range of uses. Let’s take a closer look at some of the key applications of honeycomb sheet metal:

Aerospace Industry

In the aerospace industry, honeycomb sheet metal plays a vital role in manufacturing aircraft components. It is used in aircraft flooring, interior walls, partitions, and ceilings. The lightweight nature of honeycomb panels helps reduce overall aircraft weight, leading to improved fuel efficiency and enhanced performance.

Automotive Industry

Honeycomb sheet metal has become increasingly popular in the automotive industry due to its lightweight and durable properties. It is used in car body panels, floors, doors, and crash protection systems. By incorporating honeycomb sheet metal, manufacturers can reduce vehicle weight, resulting in better fuel economy and increased safety.

Architecture and Design

In the field of architecture and design, honeycomb sheet metal offers versatility and aesthetic appeal. It is used for exterior cladding, roofing systems, ceilings, and interior partitions. Honeycomb panels can be customized in terms of colors, finishes, and sizes, allowing architects and designers to create unique and eye-catching structures. Additionally, the lightweight nature of honeycomb sheet metal makes it easier to construct and transport architectural elements.

Other applications of honeycomb sheet metal include furniture manufacturing and marine industry, where it provides lightweight and durable solutions. The versatility and performance of honeycomb sheet metal continue to make it a preferred choice across various industries.

| Industry | Applications |

|---|---|

| Aerospace | Aircraft flooring, interior walls, partitions, ceilings |

| Automotive | Car body panels, floors, doors, crash protection systems |

| Architecture and Design | Exterior cladding, roofing systems, ceilings, interior partitions |

| Furniture Manufacturing | Furniture components |

| Marine | Boat building, marine interiors |

As the demand for lightweight and high-performance materials continues to grow, honeycomb sheet metal remains at the forefront, offering endless possibilities for innovative applications.

Advantages of Aluminum Honeycomb Panels

Aluminum honeycomb panels offer numerous advantages in various construction and design applications. The honeycomb structure provides a high strength-to-weight ratio, making these panels lightweight yet exceptionally strong. The aluminum skin adds durability and corrosion resistance, ensuring the panels can withstand harsh environments. These panels are also energy-efficient, thanks to the insulation properties of the honeycomb core. The versatility of aluminum honeycomb panels allows for customization in terms of size, shape, and finish, making them suitable for a wide range of projects.

One major advantage of aluminum honeycomb panels is their lightweight nature combined with exceptional strength. This makes them ideal for applications where weight reduction is crucial, such as in aerospace and automotive industries. The lightweight properties of these panels not only reduce transportation costs but also make them easier to handle during installation. Additionally, the high strength-to-weight ratio allows for the use of thinner and lighter materials without compromising structural integrity.

Another advantage of aluminum honeycomb panels is their durability and resistance to corrosion. The aluminum skin provides a protective layer that can withstand harsh weather conditions and exposure to chemicals. This makes the panels suitable for both interior and exterior applications. Whether used for building facades, interior partitions, or automotive body panels, aluminum honeycomb panels offer long-lasting performance and low maintenance requirements.

Moreover, aluminum honeycomb panels offer excellent thermal insulation properties. The honeycomb structure creates air gaps, which act as insulators to prevent heat transfer. This helps to improve energy efficiency in buildings and reduces the need for additional insulation materials. By reducing heat loss or gain, aluminum honeycomb panels contribute to lower energy consumption and decreased utility bills.

The versatility of aluminum honeycomb panels is yet another advantage. These panels can be fabricated into various shapes and sizes, allowing for design flexibility and customization. Whether it’s for architectural cladding, furniture manufacturing, or marine applications, aluminum honeycomb panels provide designers and engineers with the freedom to create unique and functional solutions. The wide range of available finishes and colors further enhances the aesthetic appeal of these panels, allowing them to seamlessly integrate into different design styles and projects.

Advantages of Aluminum Honeycomb Panels:

- High strength-to-weight ratio

- Durability and resistance to corrosion

- Excellent thermal insulation properties

- Customization options in size, shape, and finish

- Versatility for various applications

| Type | Application | Features |

|---|---|---|

| Perforated panels | Air and light diffusion | Increased ventilation and visibility |

| Tread plate panels | Safe walking surface | Slip-resistant and durable |

| Aluminum on aluminum panels | General applications | Versatile and cost-effective |

| Cleanroom panels | Controlled environments | Hygienic and easy to clean |

| Marine panels | Corrosion resistance | Waterproof and durable |

Aluminum Honeycomb Panel Types and Configurations

When it comes to aluminum honeycomb panels, there are various types and configurations available to suit different project requirements. Whether you need increased air and light diffusion, a safe walking surface, or corrosion resistance, there is a honeycomb panel option that can meet your specific needs. Here are some of the most common types and configurations:

Perforated Panels

Perforated aluminum honeycomb panels are designed to enhance air and light diffusion. With strategically placed perforations, these panels offer improved ventilation and light transmission, making them ideal for applications such as sunshades, building facades, and decorative elements.

Tread Plate Panels

Tread plate aluminum honeycomb panels feature a textured surface that provides slip resistance, making them suitable for areas where a safe walking surface is required, such as ramps, staircases, and flooring in high-traffic spaces.

Cleanroom Panels

Cleanroom aluminum honeycomb panels are specifically designed for controlled environments that require strict cleanliness and hygiene standards. These panels have a smooth and easily cleanable surface, making them ideal for use in laboratories, pharmaceutical facilities, and hospitals.

Marine Panels

Marine-grade aluminum honeycomb panels offer excellent corrosion resistance, making them perfect for applications in marine environments. These panels are commonly used in boat building, offshore structures, and other marine applications where exposure to saltwater and harsh environmental conditions is a concern.

Signage Panels

Signage aluminum honeycomb panels are engineered to meet specific wind load requirements for outdoor signage. These panels are lightweight yet strong, making them suitable for large-scale signage installations that need to withstand high winds and other environmental stresses.

Other Configurations

In addition to the configurations mentioned above, there are various other types of aluminum honeycomb panels available, including PVC coated panels for seamless surfaces, museum panels for artwork preservation, hurricane panels for areas prone to high wind loads, curtain walls for architectural applications, and ceiling and soffit panels for walkable ceilings.

Regardless of the project requirements, there is an aluminum honeycomb panel type or configuration that can provide the strength, durability, and customization options needed. These panels offer a lightweight and versatile solution for a wide range of applications.

| Type of Aluminum Honeycomb Panel | Application |

|---|---|

| Perforated Panels | Sunshades, building facades, decorative elements |

| Tread Plate Panels | Ramps, staircases, high-traffic flooring |

| Cleanroom Panels | Laboratories, pharmaceutical facilities, hospitals |

| Marine Panels | Boat building, offshore structures, marine applications |

| Signage Panels | Outdoor signage installations |

| Other Configurations | PVC coated panels, museum panels, hurricane panels, curtain walls, ceiling and soffit panels |

Each type of aluminum honeycomb panel offers unique benefits and is designed to meet specific application requirements. By considering the different types and configurations available, you can choose the best option for your project and ensure a lightweight, strong, and durable solution.

Conclusion

Honeycomb sheet metal, particularly in the form of aluminum honeycomb panels, has emerged as a versatile and lightweight solution for a wide range of construction and design needs. With its exceptional strength, durability, and energy efficiency, it offers numerous advantages in various industries.

Whether it’s used in aerospace, automotive, architecture, or furniture manufacturing, honeycomb sheet metal proves to be a reliable choice. Its unique hexagonal structure provides exceptional strength and rigidity, allowing it to withstand extreme conditions such as high winds and impact.

Moreover, its lightweight nature not only reduces labor costs but also makes it highly suitable for applications where weight is a concern, such as in aircraft, boats, and automobiles. The energy efficiency of honeycomb sheet metal, especially aluminum honeycomb sheets, further enhances its appeal, offering excellent thermal insulation and reducing energy consumption.

With a wide range of options in terms of size, shape, and finish, honeycomb sheet metal provides endless possibilities for customization. It can be easily fabricated into different shapes and sizes, making it suitable for both decorative and structural purposes. As a result, it continues to gain popularity among engineers, designers, and manufacturers seeking lightweight and high-performing materials.

FAQ

What is honeycomb sheet metal?

Honeycomb sheet metal is a lightweight material made by bonding a thin sheet of metal to a core made of hexagonal honeycomb cells.

What are the applications of honeycomb sheet metal?

Honeycomb sheet metal is used in building facades, flooring, partitions, aircraft, boats, automobiles, and furniture manufacturing, among other applications.

What are the advantages of honeycomb sheet metal?

Honeycomb sheet metal is lightweight, strong, durable, energy-efficient, and offers customization options.

How is honeycomb sheet metal installed?

Honeycomb sheet metal is lightweight and easy to handle, making it easy to install. It reduces labor costs and is ideal for projects with quick turnaround times.

What is the energy efficiency of honeycomb sheet metal?

Honeycomb sheet metal, especially aluminum honeycomb sheets, offers excellent thermal insulation, improving energy efficiency and reducing energy consumption.

Where can I find honeycomb sheet metal suppliers?

There are many honeycomb sheet manufacturers and suppliers that offer a wide range of options in terms of size, thickness, and material.

What are the applications of aluminum honeycomb panels?

Aluminum honeycomb panels are used in aerospace, automotive, architecture, furniture manufacturing, and marine applications for their lightweight and durable properties.

What types of aluminum honeycomb panels are available?

Various types and configurations of aluminum honeycomb panels are available, including perforated panels, tread plate panels, cleanroom panels, marine panels, and more.

Why choose honeycomb sheet metal for construction and design needs?

Honeycomb sheet metal offers a unique combination of strength, durability, energy efficiency, and versatility, making it a preferred choice among engineers, designers, and manufacturers.