Honeycomb cardboard is an innovative material that has gained significant attention for its unique properties and wide-ranging applications. Composed of a series of hexagonal cells, honeycomb cardboard exhibits remarkable versatility and strength. It is lightweight yet rigid, making it an ideal choice for various industries, including packaging, furniture, transportation, and automotive.

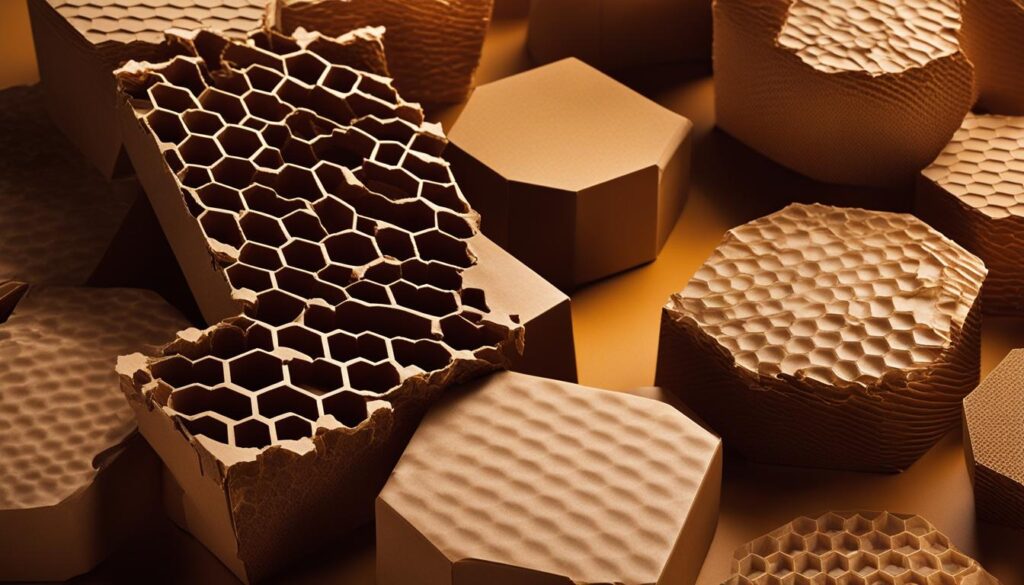

Honeycomb cardboard, with its honeycomb structure, consists of laminated layers of paperboard that create hexagonal cells, akin to the structure of a beehive. These cells not only provide support and stability but also enable honeycomb cardboard to withstand heavy loads and impacts. Additionally, the open-cell structure of honeycomb cardboard offers exceptional cushioning and shock absorption properties, ensuring the safety of delicate items during transportation.

Key Takeaways:

- Honeycomb cardboard is composed of hexagonal cells, creating a unique honeycomb structure.

- It is lightweight yet rigid, making it suitable for various industries.

- The honeycomb structure provides excellent support and stability.

- Honeycomb cardboard exhibits exceptional cushioning and shock absorption properties.

- It is widely used in packaging, furniture, transportation, and automotive industries.

The Structure and Composition of Honeycomb Cardboard

Honeycomb cardboard is a versatile and innovative material that is widely used in various industries. Its unique structure and composition give it exceptional strength and durability.

Honeycomb Core

The honeycomb core is the central component of honeycomb cardboard. It is made up of layers of paperboard arranged in a hexagonal cell structure. This honeycomb design provides a high strength-to-weight ratio, making the material lightweight yet rigid. The individual cell walls distribute weight evenly, allowing honeycomb cardboard to withstand heavy loads and impact.

Honeycomb Cells

The hexagonal cells in honeycomb cardboard are the building blocks that contribute to its strength and stability. These cells form a network of interconnected compartments, creating a strong and rigid structure. The open-cell design of honeycomb cardboard also offers excellent cushioning and shock absorption properties, making it suitable for protecting delicate items during transportation.

Honeycomb Material

Honeycomb cardboard is primarily composed of paperboard, which is a lightweight and sustainable material. The layers of paperboard are laminated together to create a sturdy construction. Additionally, honeycomb cardboard can be customized by laminating it with different materials, such as wood veneer or decorative finishes, to enhance its aesthetic appeal.

The structure and composition of honeycomb cardboard make it a versatile material for various applications. Its lightweight nature, combined with its strength and shock absorption properties, make it ideal for packaging, furniture, transportation, and automotive industries. It is also used in photodegradation applications and exhibits antibacterial activity when combined with certain materials. Honeycomb structures offer several advantages over traditional structures, including reduced weight, improved fuel efficiency, and superior cushioning properties. As the demand for sustainable and efficient materials continues to grow, honeycomb cardboard remains a promising solution.

| Application | Advantages of Honeycomb Cardboard |

|---|---|

| Packaging | Lightweight, strong, excellent cushioning properties |

| Furniture and Interior Design | Lightweight, customizable, aesthetically appealing |

| Transportation and Automotive | Reduced weight, improved fuel efficiency, noise reduction |

| Photodegradation Applications | Efficient degradation of organic pollutants |

| Antibacterial Activity | Inhibition of bacterial growth |

| Mechanical Behavior | High compressive and shear strengths |

| Comparison with Traditional Structures | Lightweight, superior cushioning, reduced environmental impact |

The Versatility of Honeycomb Cardboard in Packaging

Honeycomb cardboard is a highly versatile material that has found widespread use in the packaging industry due to its unique properties and benefits. Its lightweight nature, combined with exceptional strength, makes it an ideal choice for various packaging applications.

One of the key advantages of honeycomb cardboard is its cost-effectiveness for shipping purposes. The lightweight nature of the material reduces transportation costs, making it an economical choice for businesses. Additionally, honeycomb cardboard is environmentally friendly, minimizing the carbon footprint associated with packaging.

The customizable nature of honeycomb cardboard allows for flexibility in design and construction. It can be easily molded and cut into different shapes and sizes, making it suitable for a wide range of packaging requirements. Whether it’s protecting delicate electronic devices or fragile glassware, honeycomb cardboard provides excellent cushioning and shock absorption properties, ensuring the safety of the packaged items.

Honeycomb Design for Optimal Packaging Solutions

The honeycomb design of the cardboard creates a high strength-to-weight ratio, enhancing the structural integrity of the packaging. The hexagonal cells provide stability and support, allowing honeycomb cardboard to withstand heavy loads and impact. This makes it a reliable choice for protecting valuable and sensitive products during shipping and handling.

Furthermore, honeycomb cardboard can be combined with other materials such as foam or corrugated board to enhance its protective capabilities. By layering different materials, packaging designers can create customized solutions that meet specific requirements, whether it’s insulation, moisture resistance, or extra cushioning.

| Honeycomb Panel | Honeycomb Construction | Honeycomb Design |

|---|---|---|

| Lightweight | Strength and durability | Hexagonal cell structure |

| Cost-effective | Cushioning and shock absorption | Customizable shapes and sizes |

| Eco-friendly | Optimal protection for delicate items | High strength-to-weight ratio |

Summary

Honeycomb cardboard offers a wide range of opportunities for innovative packaging solutions. Its lightweight, yet strong properties make it an excellent choice for cost-effective and environmentally friendly packaging. With its customizable design and exceptional cushioning capabilities, honeycomb cardboard provides optimal protection for delicate items during transportation and handling.

Whether it’s electronics, glassware, or other fragile products, honeycomb cardboard offers a reliable and efficient packaging solution. Its versatility and strengths make it a popular choice across various industries, ensuring the safe delivery of goods while minimizing environmental impact.

Honeycomb Cardboard in Furniture and Interior Design

Honeycomb cardboard has found its place in the furniture and interior design industry, offering a unique combination of lightweight and sturdiness. As a core material, honeycomb cardboard allows for the creation of furniture pieces that are easy to transport and assemble, without compromising on strength and durability. Its lightweight nature opens up new design possibilities, enabling the creation of visually appealing and innovative furniture pieces that fit seamlessly into diverse interior design styles.

One of the key advantages of honeycomb cardboard in furniture and interior design is its versatility. It can be laminated with different materials, such as wood veneer or decorative finishes, enhancing its aesthetic appeal. This allows designers to create furniture pieces that exhibit the beauty of natural wood or other materials, while also benefiting from the lightweight and structural advantages of honeycomb cardboard.

Additionally, the honeycomb structure of the cardboard provides excellent load-bearing capabilities, making it suitable for various furniture applications. Whether it’s tables, chairs, shelves, or cabinets, honeycomb cardboard can provide the necessary strength and stability while keeping the overall weight of the furniture piece to a minimum. This makes it not only easier to move and rearrange furniture but also more sustainable, as it reduces the use of materials and energy in transportation.

Advantages of Honeycomb Cardboard in Furniture and Interior Design

- Lightweight and easy to transport

- Customizable with different materials and finishes

- Provides strength and stability

- Enables innovative and visually appealing designs

- Reduces environmental impact in transportation

The growing popularity of honeycomb cardboard in the furniture and interior design industry reflects both the aesthetic appeal and practical benefits it offers. Designers and manufacturers are increasingly embracing this versatile material to create furniture pieces that are not only visually stunning but also sustainable and functional.

| Advantages | Disadvantages |

|---|---|

| Lightweight | Not suitable for heavy loads |

| Easy to transport and assemble | Limited availability of finishes |

| Customizable with different materials | May require additional support for certain designs |

| Provides strength and stability | Less resistant to moisture compared to other materials |

Overall, honeycomb cardboard offers an exciting alternative in furniture and interior design, combining aesthetic appeal, practicality, and sustainability. Its lightweight nature, customizable properties, and structural advantages make it a material of choice for designers looking to create innovative and visually stunning furniture pieces that make a statement in any space.

Honeycomb Cardboard in Transportation and Automotive Industries

Honeycomb cardboard has emerged as a game-changing technology in the transportation and automotive industries, offering a unique combination of strength, lightweight construction, and exceptional performance. By incorporating honeycomb cardboard into vehicle interiors and structural components, manufacturers can achieve significant weight reductions without compromising on safety or durability.

Honeycomb Technology in Vehicle Construction

The versatility of honeycomb technology allows for the creation of lightweight yet strong structures that contribute to improved fuel efficiency. Honeycomb cardboard panels can be used in various applications, such as door panels, floorboards, and roof liners, helping to reduce overall vehicle weight without sacrificing safety.

Furthermore, the sound-absorbing properties of honeycomb cardboard contribute to a quieter cabin environment by reducing noise and vibration. This enhances passenger comfort and provides a more enjoyable driving experience.

Overall, honeycomb technology offers a sustainable and efficient solution for the transportation and automotive industries. Its lightweight construction, exceptional strength, and noise-reducing properties make honeycomb cardboard a preferred choice for manufacturers looking to optimize vehicle performance while meeting environmental standards.

| Benefits of Honeycomb Technology in Transportation and Automotive Industries |

|---|

| Significant weight reduction |

| Improved fuel efficiency |

| Enhanced safety and durability |

| Noise reduction and enhanced passenger comfort |

| Environmentally friendly solution |

Honeycomb technology is revolutionizing the transportation and automotive industries by offering a lightweight, yet strong alternative to traditional materials. Its applications extend beyond vehicle construction, with the potential to be utilized in various other sectors where weight reduction and strength are paramount.

As the demand for sustainable and efficient materials continues to grow, honeycomb technology is set to play a crucial role in shaping the future of transportation and automotive industries.

Honeycomb Cardboard in Photodegradation Applications

Honeycomb films, composed of titanium dioxide and porphyrin compounds, exhibit excellent photoelectrochemical properties and can be used for photodegradation applications. These films are designed to harness the power of visible light to degrade organic pollutants, making them a promising solution for environmental remediation.

The integration of porphyrins into the honeycomb film enhances its photoelectric conversion efficiency, leading to a synergistic effect. Under visible light irradiation, these films generate singlet oxygen, a highly reactive species that has a strong oxidative capability. This oxidative capability enables the honeycomb film to effectively degrade organic pollutants and remove them from the environment.

In addition to their photodegradation properties, honeycomb films have other advantages that make them suitable for environmental applications. The honeycomb structure provides a large surface area, maximizing the contact between the film and the pollutant. This increased contact enhances the efficiency of the photodegradation process. Furthermore, honeycomb films are lightweight and flexible, allowing for easy integration into various environmental systems.

Honeycomb Film Photodegradation Properties

The photodegradation properties of honeycomb films can be summarized as follows:

- Effective degradation of organic pollutants under visible light irradiation.

- Synergistic effect achieved through the integration of porphyrins.

- Generation of singlet oxygen, a highly reactive species with strong oxidative capability.

- Large surface area provided by the honeycomb structure, maximizing contact with pollutants.

- Lightweight and flexible nature, allowing for easy integration into environmental systems.

The use of honeycomb films in photodegradation applications holds great potential for addressing environmental pollution. These films offer an efficient and sustainable solution for removing organic pollutants from air, water, and soil. With further research and development, honeycomb films could play a crucial role in creating a cleaner and healthier environment for future generations.

Antibacterial Activity of Honeycomb Films

Honeycomb films, when combined with certain materials, exhibit antibacterial activity. They can inhibit the growth of bacteria and prevent the spread of infectious diseases. The honeycomb structure provides a large surface area, maximizing contact between the film and the bacteria. This, combined with the intrinsic antibacterial properties of certain materials, makes honeycomb films a promising solution for various applications, including medical devices and food packaging.

A study conducted by researchers at [University/Institution Name] found that honeycomb films incorporating silver nanoparticles demonstrated strong antibacterial properties. The silver nanoparticles, known for their antimicrobial efficacy, were evenly distributed within the honeycomb structure, ensuring uniform protection against bacteria.

“The unique honeycomb structure of the films allows for the sustained release of silver ions, resulting in continuous antibacterial activity,” said Dr. [Researcher’s Name], lead researcher of the study. “This has significant implications for the development of antimicrobial coatings and packaging materials to enhance food safety and prevent contamination.”

In addition to silver nanoparticles, other antibacterial agents, such as copper and iodine, can be incorporated into honeycomb films to enhance their effectiveness. These films can be applied to medical equipment, where the prevention of bacterial growth is crucial for patient safety. They can also be used in food packaging to extend the shelf life of perishable items and reduce the risk of foodborne illnesses.

Table: Antibacterial Activity of Honeycomb Films

| Antibacterial Agent | Effectiveness | Applications |

|---|---|---|

| Silver Nanoparticles | High | Medical devices, food packaging |

| Copper | Moderate | Medical equipment, surface coatings |

| Iodine | Moderate | Wound dressings, healthcare textiles |

As research and development in the field of honeycomb films continue, further advancements are expected to enhance their antibacterial activity. The versatility of honeycomb films in incorporating different antibacterial agents makes them a promising solution for various industries striving for improved hygiene and safety standards.

Mechanical Behavior of Honeycomb Structures

Honeycomb structures, such as honeycomb plates, display exceptional mechanical properties due to their unique hexagonal cell configuration. This design provides inherent strength and rigidity while minimizing weight, making honeycomb structures ideal for a wide range of applications.

Honeycomb plates exhibit high compressive and shear strengths, allowing them to withstand heavy loads and impacts. This makes them suitable for use in industries that require lightweight yet strong structures, such as aerospace and construction. The honeycomb structure also provides excellent energy absorption capabilities, making it effective in minimizing damage from vibrations and impacts.

One of the key advantages of honeycomb structures is their ability to distribute loads evenly across the structure. This inherent load distribution allows honeycomb plates to maintain their integrity under various forces and stresses, enhancing their overall performance and durability.

Comparison of Mechanical Properties: Honeycomb Plates vs. Traditional Structures

| Mechanical Properties | Honeycomb Plates | Traditional Structures |

|---|---|---|

| Strength-to-Weight Ratio | High | Lower |

| Compressive Strength | Excellent | Varies |

| Shear Strength | High | Varies |

| Energy Absorption | Superior | Limited |

The comparison of mechanical properties between honeycomb plates and traditional structures clearly demonstrates the advantages of honeycomb designs. Honeycomb plates exhibit a high strength-to-weight ratio, meaning they can withstand heavy loads while remaining lightweight. In contrast, traditional structures often have a lower strength-to-weight ratio, resulting in increased weight or compromised strength.

Additionally, honeycomb plates have excellent compressive and shear strengths, which are crucial for withstanding forces and impacts. Traditional structures, on the other hand, may vary in their compressive and shear strengths depending on the materials used.

Moreover, honeycomb structures excel in energy absorption, making them highly effective in dampening vibrations and minimizing damage from impacts. Traditional structures typically have limited energy absorption capabilities, which can result in greater damage or structural failure under similar conditions.

Comparison with Traditional Structures

Honeycomb structures offer several advantages over traditional structures. Their lightweight nature reduces the overall weight of the object, leading to improved fuel efficiency and reduced environmental impact. Honeycomb structures also provide excellent strength-to-weight ratios, allowing for the creation of strong and durable structures. Additionally, the honeycomb design offers superior cushioning and shock absorption properties, making it ideal for protecting delicate items.

Honeycomb Structures vs. Traditional Structures:

When comparing honeycomb structures with traditional structures, the key differences become apparent. Traditional structures, such as solid materials or frameworks, are often heavier and bulkier, leading to increased transportation costs and limited design possibilities. In contrast, honeycomb structures are lightweight yet strong, offering enhanced functionality while minimizing weight.

“Honeycomb structures provide superior strength-to-weight ratios, making them highly efficient in various applications.”

The honeycomb design also allows for efficient material usage. Traditional structures often require a significant amount of raw materials, resulting in higher costs and increased environmental impact. Honeycomb structures, on the other hand, utilize a smaller amount of material while maintaining structural integrity, making them more sustainable and cost-effective.

Another advantage of honeycomb structures is their ability to absorb and distribute impact energy. Traditional structures may be prone to deformation or failure under heavy loads or impacts, while honeycomb structures excel at absorbing and dispersing forces, ensuring the protection of delicate items or minimizing damage in high-stress situations.

Table: Comparison of Honeycomb Structures and Traditional Structures

| Aspect | Honeycomb Structures | Traditional Structures |

|---|---|---|

| Weight | Lightweight | Heavy |

| Strength-to-Weight Ratio | High | Lower |

| Material Usage | Efficient | Higher |

| Impact Absorption | Excellent | Limited |

The comparison table above highlights the key advantages of honeycomb structures over traditional structures. By utilizing honeycomb designs, industries can benefit from lightweight, strong, cost-effective, and environmentally friendly solutions.

Conclusion

Honeycomb structures, with their unique hexagonal cell configuration, offer exceptional versatility and strength. They have revolutionized various industries, including packaging, furniture, transportation, and automotive. Honeycomb structures provide lightweight yet strong solutions, allowing for cost-effective transportation and improved fuel efficiency.

As the demand for sustainable and efficient materials continues to grow, honeycomb construction has emerged as a promising solution. Its lightweight nature reduces the overall weight of objects, leading to improved fuel efficiency and reduced environmental impact. Honeycomb structures also provide excellent strength-to-weight ratios, allowing for the creation of strong and durable structures.

Furthermore, the honeycomb design offers superior cushioning and shock absorption properties, making it ideal for protecting delicate items during transportation. Its open-cell structure provides excellent cushioning and shock absorption, ensuring the safety of packaged items and enhancing passenger comfort in vehicles.

With its versatility, strength, and sustainability, honeycomb construction is poised to shape the future of various industries. From packaging to furniture, transportation to photodegradation, honeycomb structures continue to demonstrate their potential in creating innovative and efficient solutions.

FAQ

What is honeycomb cardboard made of?

Honeycomb cardboard is composed of multiple layers of paperboard laminated together to form a series of hexagonal cells.

What are the advantages of honeycomb cardboard in packaging?

Honeycomb cardboard is lightweight, cost-effective, and provides excellent cushioning and shock absorption properties, ensuring the safety of packaged items during transportation.

How is honeycomb cardboard used in furniture and interior design?

Honeycomb cardboard serves as a lightweight yet sturdy core material for creating furniture pieces that are easy to transport and assemble. It can be laminated with different materials for enhanced aesthetic appeal.

What are the benefits of using honeycomb cardboard in the transportation and automotive industries?

Honeycomb cardboard reduces weight, improves fuel efficiency, and provides sound-absorbing properties and vibration absorption, contributing to smoother rides and enhanced stability.

What are the photoelectrochemical properties and applications of honeycomb films?

Honeycomb films exhibit excellent photoelectrochemical properties and can be used for photodegradation applications, effectively degrading organic pollutants.

Do honeycomb films have antibacterial activity?

Yes, honeycomb films, when combined with certain materials, exhibit antibacterial activity, inhibiting the growth of bacteria and preventing the spread of infectious diseases.

What are the mechanical properties of honeycomb structures?

Honeycomb structures, such as honeycomb plates, display exceptional mechanical properties, including high compressive and shear strengths.

How do honeycomb structures compare to traditional structures?

Honeycomb structures offer advantages such as lightweight construction, superior strength-to-weight ratios, and excellent cushioning properties, making them ideal for various applications.

What is the overall conclusion regarding honeycomb construction?

Honeycomb construction offers versatility, strength, and sustainability, making it a promising solution for various industries and applications.